Recyclable lightweight single Component Composite Material developed for Injection-Molded Components

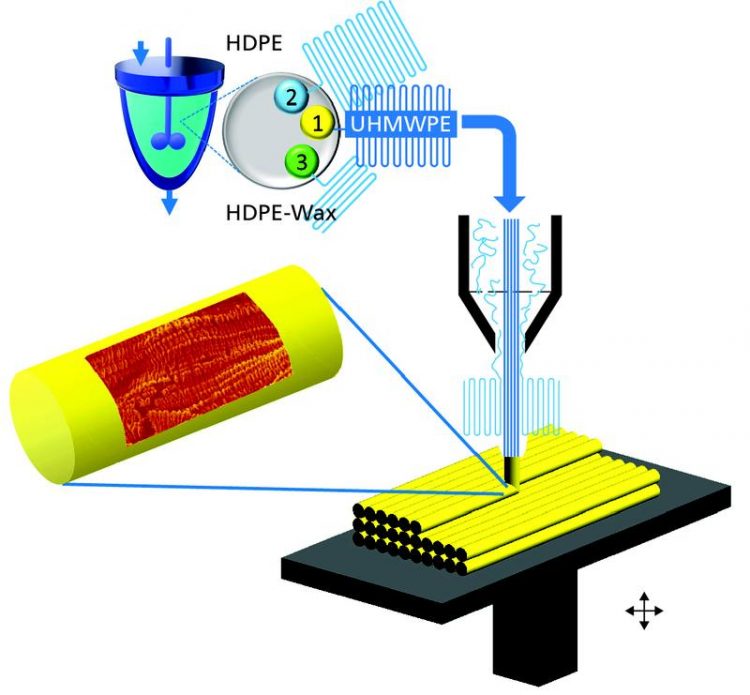

Using a catalyst, different unbranched PE chains are produced (top) and the fiber structures produced in the 3D pressure nozzle are deposited in the desired orientation in the printed component. Fraunhofer Institute for Mechanics of Materials IWM

The hydrocarbons polyethylene (PE) and polypropylene (PP) account for a good half of all polymers produced worldwide. PE can be found in many plastic products used every day. As a pure grade material, it is simple and virtually infinitely reusable: used products are rasped, melted and formed into new components with consistently good quality.

Or PE is heated and converted back into raw materials for the chemical industry or into building blocks for the production of hydrocarbon materials – completely without residue.

For this reason and because of their low weight, hydrocarbon materials are generally ideal for sustainable lightweight construction: for example in the automotive industry, which by law has to prove a certain percentage of the recyclability of its products.

However, up to this point it has not been possible to manufacture load-bearing components from regular PE because on its own it is not a strong enough material. Until now, fillers – mainly carbon or glass fibers – have been used for reinforcement.

The addition of fillers has, however, a negative impact on the cost and the energy, raw material, environmental balance: production and recycling are considerably more difficult and expensive.

So-called ultra-high molecular weight PE (UHMWPE), used as a high-performance material in medical implants such as acetabular cups or knee joints, offers an alternative. However, this pure, high-strength and abrasion-resistant material cannot be processed by injection molding:

It has to be pressed into a mold as a powder, sintered and then milled into the exact component in a complex and cost-intensive process. Although UHMWPE fibers can achieve the strength of steel, they are expensive and unsuitable for material recycling.

Pure grade PE composite via a controlled catalytic process

“In the SusCOMP project, we carried out research on All-PE single component composites that can be processed by injection molding and directly reinforce themselves. Of course, we were particularly interested in the mechanical properties of these composites,” explains Raimund Jaeger, leader of the Polymer Tribology and Biomedical Materials group at the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg.

“DSM already spins high-performance fibers from long UHMWPE molecular chains that orient themselves along the fiber direction, so-called “Dyneema” fibers. It would be technically possible to incorporate such fibers into PE as reinforcements, but this would involve a great deal of work and expense and would not be suitable for material recycling.

Prof. Dr. Rolf Mülhaupt and his team at the Freiburg Materials Research Centre (FMF) at the University of Freiburg found the solution to this challenge by finely distributing different catalysts, which can be used to produce PE in different chain lengths, along the same catalyst carrier. In the subsequent synthesis of PE using ethylene polymerization, mixtures of low, medium and ultra-high molecular weight PE, known as reactor blends, are simultaneously produced on this catalyst.

“With this trick, PE blends are produced directly during polymerization that can be injection molded without any problems,” explains Prof. Dr. Mülhaupt. The process avoids high viscosities, which are normally a challenge when a high proportion of UHMWPE molecular chains are to be processed in injection molding.

High shear currents, which occur during injection molding in narrow injection molds, cause fiber-like UHMWPE structures to form from the ultra-high molecular weight fraction via self-organization of the material. These fibers reinforce the composite and even orient themselves in the desired direction during injection molding, thus ensuring mechanical stability.

These components are also easy to recycle: “We have recycled a total of ten samples of these materials and always obtained the same good quality, since the desired material structures are formed again and again through self-organization,” says Prof. Dr. Mülhaupt.

The scientists at the Fraunhofer IWM tested samples of this new high-performance material for their material properties. The mechanical properties show: many applications are conceivable, for example long furniture parts as well as rail and shutter guides or parts for car interiors. In addition to their low weight, the components also have the advantage that water-based lubricants are very well tolerated.

In the future: pure PE composites on demand

The follow-up project, 3D-SusCOMP, now involves processing the material using a 3D printer. Previously, the good properties of All-PE composites could only be achieved if the polymers were oriented when injecting them into a narrow mold. However, the reinforcement by self-organization exclusively occurs in the direction specified by the molding tool.

This is already a major step forward, but other component shapes and composite materials, so-called multidirectional composites, are also desirable. The scientists found out: the fiber structures also form in the nozzle of a 3D printer. In contrast to injection molding, however, their orientation in the component can be controlled by the movement of the print head.

As a result, many new applications for this recyclable material are conceivable: in addition to light weight gear wheels in automobiles or for the food industry, it is also possible to produce robot grippers which adapt to the shape of a part, medical orthotics or connectors from a “single mold”.

The two projects SusCOMP and 3D-SusCOMP of the Sustainability Centre Freiburg are funded by the state of Baden-Württemberg and the Fraunhofer-Gesellschaft. The development of catalysts is based on many years of BMBF-funded research cooperation between the Freiburg Materials Research Centre and the world leader LyondellBasell in Frankfurt.

Extra Info: The production of polyethylene materials

The starting material for the production of polyethylene (PE) is ethylene: a monomer obtained from crude oil by the “cracking” process and consisting only of carbon and hydrogen atoms. In the production of PE, the polymerization process, many ethylene molecules are assembled into long molecule chains. Depending on the manufacturing process, they are branched (LDPE) or can also be produced unbranched (HDPE) using a catalyst. Special catalysts supply particularly long-chain PE (UHMWPE). The longer and more unbranched the chains are, the more likely they are to form semi-crystalline structures that increase mechanical stability. This is why, for example, elastic films are made of branched LDPE and parts subject to high mechanical stress, such as gear wheels, are made of UHMWPE.

Dr. Raimund Jaeger l Phone +49 761 5142-284 l Raimund.jaeger@iwm.fraunhofer.de | Fraunhofer Institute for Mechanics of Materials IWM l www.iwm.fraunhofer.de/en

Prof. Dr. Rolf Mülhaupt l Phone +49 761 203-6273l rolf.muelhaupt@makro.uni-freiburg.de | Institute for Macromolecular Chemistry , Freiburg l www.makro.uni-freiburg.de

https://www.iwm.fraunhofer.de/en/press/press-releases/27_08_19_Recyclable_lightw… – Press Release online

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

An Endless Loop: How Some Bacteria Evolve Along With the Seasons

The longest natural metagenome time series ever collected, with microbes, reveals a startling evolutionary pattern on repeat. A Microbial “Groundhog Year” in Lake Mendota Like Bill Murray in the movie…

Witness Groundbreaking Research on Achilles Tendon Recovery

Achilles tendon injuries are common but challenging to monitor during recovery due to the limitations of current imaging techniques. Researchers, led by Associate Professor Zeng Nan from the International Graduate…

Why Prevention Is Better Than Cure—A Novel Approach to Infectious Disease Outbreaks

Researchers have come up with a new way to identify more infectious variants of viruses or bacteria that start spreading in humans – including those causing flu, COVID, whooping cough…