A microbial plastic factory for high-quality green plastic

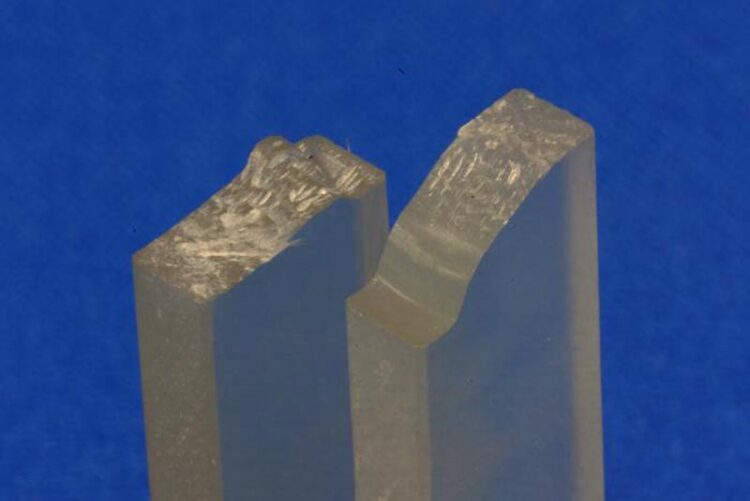

A fractured stick of lactic acid with added ultra-high molecular weight LAHB (left) exhibits obvious white discolorations at the fracture face, which is a sign of plastic deformation in toughened materials. On the other hand, pure polylactic acid (right) does not show such whitening, which is a sign of brittle materials.

Credit: KOH Sangho

Engineered bacteria can produce a plastic modifier that makes renewably sourced plastic more processable, more fracture resistant and highly biodegradable even in sea water. The Kobe University development provides a platform for the industrial-scale, tunable production of a material that holds great potential for turning the plastic industry green.

Plastic is a hallmark of our civilization. It is a family of highly formable (hence the name), versatile and durable materials, most of which are also persistent in nature and therefore a significant source of pollution. Moreover, many plastics are produced from crude oil, a non-renewable resource. Engineers and researchers worldwide are searching for alternatives, but none have been found that exhibit the same advantages as conventional plastics while avoiding their problems. One of the most promising alternatives is polylactic acid, which can be produced from plants, but it is brittle and does not degrade well.

To overcome these difficulties, Kobe University bioengineers around TAGUCHI Seiichi together with the biodegradable polymer manufacturing company Kaneka Corporation decided to mix polylactic acid with another bioplastic, called LAHB, which has a range of desirable properties, but most of all it is biodegradable and mixes well with polylactic acid. However, in order to produce LAHB, they needed to engineer a strain of bacteria that naturally produces a precursor, by systematically manipulating the organism’s genome through the addition of new genes and the deletion of interfering ones.

In the scientific journal ACS Sustainable Chemistry & Engineering, they now report that they could thus create a bacterial plastic factory that produces chains of LAHB in high amounts, using just glucose as feedstock. In addition, they also show that by modifying the genome, they could control the length of the LAHB chain and thus the properties of the resulting plastic. They were thus able to produce LAHB chains up to ten times longer than with conventional methods, which they call “ultra-high molecular weight LAHB.”

Most importantly, by adding LAHB of this unprecedented length to polylactic acid, they could create a material that exhibits all the properties the researchers had aimed for. The resulting highly transparent plastic is much better moldable and more shock resistant than pure polylactic acid, and also biodegrades in seawater within a week. Taguchi comments on this achievement, saying “By blending polylactic acid with LAHB, the multiple problems of polylactic acid can be overcome in one fell swoop, and the so modified material is expected to become an environmentally sustainable bioplastic that satisfies the conflicting needs of physical robustness and biodegradability.”

The Kobe University bioengineers, however, dream bigger. The strain of bacteria they used in this work is in principle able to use CO2 as a raw material. It should thus be possible to synthesize useful plastics directly from the greenhouse gas. Taguchi explains, “Through the synergy of multiple projects, we aim to realize a biomanufacturing technology that effectively links microbial production and material development.”

This research was commissioned by the New Energy and Industrial Technology Development Organization of Japan (grant JPNP20005) and funded by the Ministry of Education, Culture, Sports, Science and Technology Japan (grant 19K22069) and the Japan Science and Technology Agency (grant JPMJTM19YC). It was conducted in collaboration with researchers from Kaneka Corporation and the National Institute of Advanced Industrial Science and Technology.

Kobe University is a national university with roots dating back to the Kobe Commercial School founded in 1902. It is now one of Japan’s leading comprehensive research universities with nearly 16,000 students and nearly 1,700 faculty in 10 faculties and schools and 15 graduate schools. Combining the social and natural sciences to cultivate leaders with an interdisciplinary perspective, Kobe University creates knowledge and fosters innovation to address society’s challenges.

Journal: ACS Sustainable Chemistry & Engineering

DOI: 10.1021/acssuschemeng.3c07662

Method of Research: Experimental study

Subject of Research: Cells

Article Title: Microbial platform for tailor-made production of biodegradable polylactide modifier: Ultra-high-molecular weight lactate-based polyester LAHB

Article Publication Date: 9-Apr-2024

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…