ADIR Project: Lasers Recover Valuable Materials

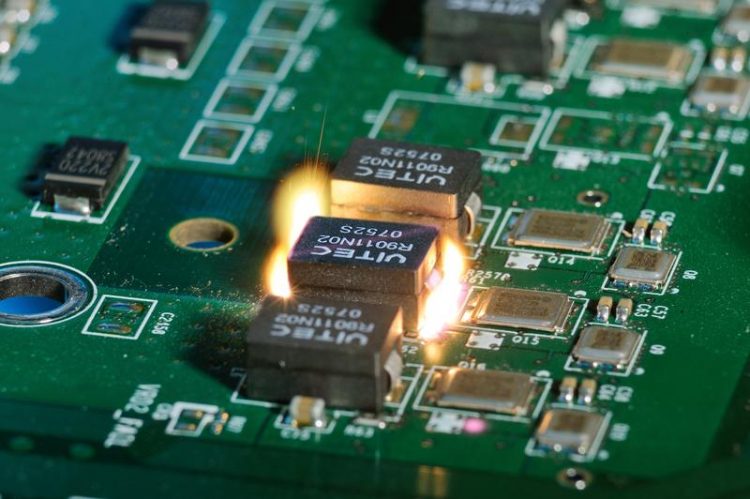

Contactless exposure and unsoldering of circuit board components by means of laser radiation in a recycling process of the “ADIR” project.

The Fraunhofer Institute for Laser Technology ILT in Aachen is coordinating this project, which is being funded by the EU as part of the Horizon 2020 program.

Conventional material recycling frequently relies on bulk material flow solutions, which use shredding and pyrometallurgical processes. They focus primarily on recovering precious metals such as copper, gold and silver, but are unable to recover other rare materials.

“Elements such as tantalum and tungsten, or rare earths such as neodymium, will continue to play an important role in the industrial manufacture of high-tech electronics,” explains project coordinator Prof. Reinhard Noll from Fraunhofer ILT. “Our new reverse production approach will ensure that we fully exploit the potential that so far has gone untapped.”

Using Laser Technology to Operate Sustainably: Reverse Production

ADIR explores the feasibility of new technologies for the next generation of urban mining. Automated, flexible processes enable the modern recycling of treasures found in urban environments such as defective or unused electronic devices.

Special machines for automated disassembly and removal will combine laser technology, robotics, modern image processing and information technology at different stages of the process. Lasers are suited for a range of tasks – for example, for 3D measurement technology, real-time identification of constituent elements, or contact-free uncovering and desoldering of electronic components. New sorting fractions help to retrieve high-quality materials in a short amount of time.

After analyzing the requirements for materials handling and testing various recycling methods, the ADIR project began developing the process. The scientists first optimized individual process steps for sorting certain components and further processing after each stage on a laboratory scale, and are now developing suitable software and hardware modules that can be combined to form a machine. In 2018, the project partners will build a demonstrator in a recycling plant to enable an experimental validation in an industrial setting. Efficiency and a high level of usability are top priorities.

In February 2016, Fraunhofer ILT launched the sister project i-Recycle, scheduled to run until 2019. Its goal is to collect old, no longer used cell phones from the Fraunhofer-Gesellschaft for the ADIR project and to make them available for testing and research and development work.

Independence Through Combined Expertise

The ADIR consortium comprises laser and automation process developers as well as metal recycling experts. Their objective is to achieve sustainable, practical recovery of raw and other materials from used electronics. “Strategically, it’s also about reducing the EU’s dependence on resources and expensive material imports,” says project manager Dr. Cord Fricke-Begemann from Fraunhofer ILT. Making phones available for testing and jointly developing next-generation recycling: with its ADIR and i-Recycle projects, the Fraunhofer-Gesellschaft is taking on a leading role in the up-and-coming field of urban mining.

Details of the projects and the latest information on their progress can be found on our website: https://www.adir.eu

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…