An entirely new display technology

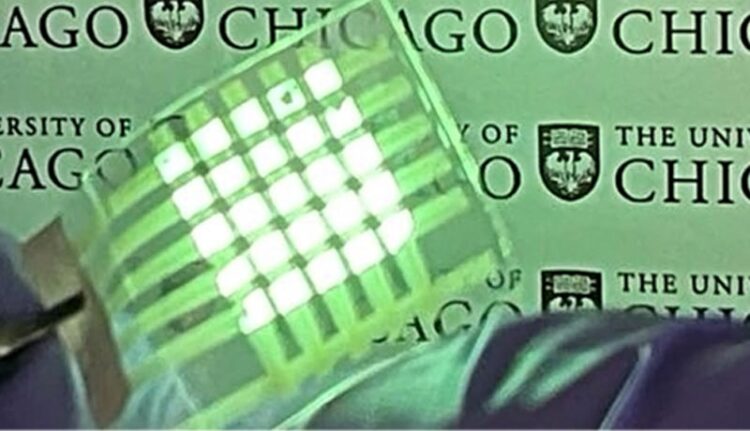

A material developed by Asst. Prof. Sihong Wang and Prof. Juan de Pablo can stretch more than twice its original length without disrupting its ability to emit light and display a clear image. (Image courtesy of Wang Group)

Image courtesy of UChicago Wang Group

Researchers develop stretchable OLED display.

Imagine a thin, digital display so flexible that you can wrap it around your wrist, fold it in any direction, or curve it over your car’s steering wheel. Researchers at the Pritzker School of Molecular Engineering (PME) at the University of Chicago have designed just such a material, which can bend in half or stretch to more than twice its original length while still emitting a fluorescent pattern.

The material, described in Nature Materials, has a wide range of applications, from wearable electronics and health sensors to foldable computer screens.

“One of the most important components of nearly every consumer electronic we use today is a display, and we’ve combined knowledge from many different fields to create an entirely new display technology,” said Sihong Wang, assistant professor of molecular engineering, who led the research with Juan de Pablo, Liew Family Professor of Molecular Engineering.

“This is the class of material you need to finally be able to develop truly flexible screens,” added de Pablo. “This work is really foundational and I expect it to allow many technologies that we haven’t even thought of yet.”

Making flexible, light-up polymers

The displays on most high-end smartphones, as well as a growing number of televisions, use OLED (organic light-emitting diode) technology, which sandwiches small organic molecules between conductors. When an electrical current is switched on, the small molecules emit a bright light. The technology is more energy-efficient than older LED and LCD displays and praised for its sharp pictures. However, the molecular building blocks of OLEDs have tight chemical bonds and stiff structures.

“The materials currently used in these state-of-the-art OLED displays are very brittle; they don’t have any stretchability,” said Wang. “Our goal was to create something that maintained the electroluminescence of OLED but with stretchable polymers.”

Wang and de Pablo knew what it takes to imbue stretchability into materials—long polymers with bendable molecular chains—and also knew what molecular structures were required for an organic material to emit light very efficiently. They set out to create new polymers that integrated both properties.

“We have been able to develop atomic models of the new polymers of interest and, with these models, we simulated what happens to these molecules when you pull on them and try to bend them,” explained de Pablo. “Now that we understand these properties at a molecular level, we have a framework to engineer new materials where flexibility and luminescence are optimized.”

Armed with computational predictions for new flexible electroluminescent polymers, they built several prototypes. Just as the model had predicted, the materials were flexible, stretchable, bright, durable and energy efficient.

A key feature in their design was the use of “thermally activated delayed fluorescence,” which let the materials convert electrical energy into light, in a highly efficient way. This third-generation mechanism for organic emitters can provide materials with performance on par with commercial OLED technologies.

A vision for wearable electronics

Wang has previously developed stretchable neuromorphic computing chips that can collect and analyze health data on a kind of flexible Band-Aid. The ability to now create stretchable displays adds to his growing suite of tools for next-generation wearable electronics.

Bendable materials that emit light, he said, can not only be used to display information, but can be integrated into wearable sensors that require light. Sensors measuring blood oxygenation and heart rate, for instance, typically shine a light through blood vessels to sense blood flow.

Wang said a bendable light-up material also could, eventually, be integrated into implantable devices, such as those that use light to control the activity of neurons in the brain (this kind of so-called optogenetics is currently used only in animal experiments to better understand the brain and brain diseases).

“My overall dream is to make all the essential components for a full system of wearable electronics, from sensing to processing to displaying information,” Wang explained. “Having this stretchable light-emitting material is another step toward that dream.”

The team is planning to develop new iterations of the display in the future, integrating additional colors into the fluorescence and improving the efficiency and performance.

“The goal is to eventually get to the same level of performance that existing commercial technologies have,” said Wang.

Journal: Nature Materials

DOI: 10.1038/s41563-023-01529-w

Article Title: “High-efficiency stretchable light-emitting polymers from thermally activated delayed fluorescence

Article Publication Date: 6-Apr-2023

Media Contact

Meredith Davis

University of Chicago

meredithdavis@uchicago.edu

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…