Automated joining of complex glass parts

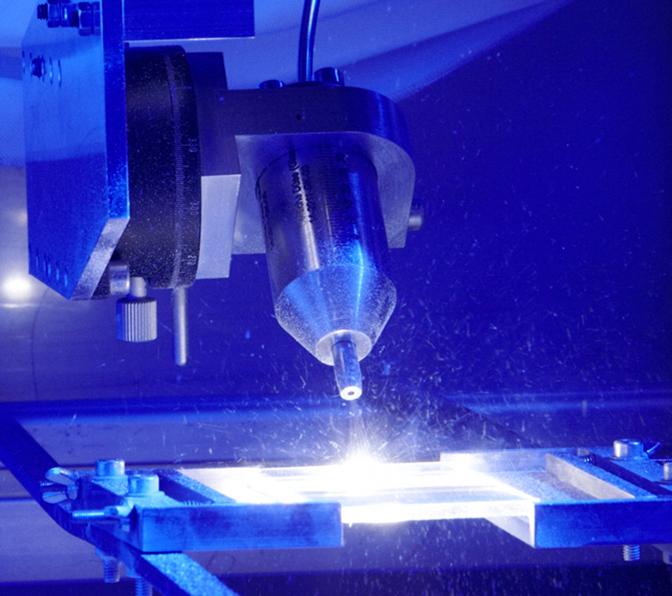

Laser-based joining of glass parts using powder filler material. Photo: LZH

Scientists of the Glass Group at the Laser Zentrum Hannover e.V. (LZH) have therefore developed a process for the laser-based joining of borosilicate and quartz glass. In order to achieve a constant quality of the parts, the surface temperature is controlled without contact during the process, and thus, the glass viscosity for joining is reduced in a pre-defined way.

Powder filler material is used for bridging the gap. The results of the project show that the new process setup is very well suited for automated manufacturing. The research work was supported by the German Federal Ministry of Economics and Technology.

Complex glass parts are, in most cases, manufactured manually by a glass apparatus maker using a gas flame. Since the process cannot be entirely controlled, the quality fluctuates. In order to be able to automate the production of complex parts, e.g. for chemical apparatus engineering, LZH scientists have developed a laser-based process for joining glass parts made of borosilicate and quartz glass.

The special feature of the process is an integrated temperature control that regulates the viscosity of the parts in a pre-defined way during the welding process: Here, a CO2 laser beam source provides the required amount of heat energy. The temperature is measured without contact using a pyrometer.

In order bridge gaps at, for example, L angle geometries, glass powder is added as filler material during the joining process. In doing so, the glass powder is melted and forms a homogeneous welding seam with a constant bead height. The new process setup enables automated joining of glass in various welding configurations, such as butt joints, fillet joints and L angles.

The „Research Association Technique and Glass“ (FTG e.V.) submitted the application for the research project titled “laser-based joining of glass parts using powder filler material” (powder joining). The commitment and know-how of the FTG members significantly contributed to the success of the project.

The IGF project no. 17029 N „laser-based joining of glass parts using powder filler material“ of the „Research Association Tech-nique and Glass“ (FTG e.V., Bronnbach 28, 97877 Wertheim, Germany) was supported by the German Federation of Industrial Research Associations (AiF e.V.) within the scope of the Industrial Collective Research Programme (IGF) of the German Federal Ministry of Economics and Technology on the basis of a decision by the German Bundestag.

The complete project report is available upon request to presse@lzh.de.

Media Contact

More Information:

http://www.lzh.deAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…