Bacteria as Blacksmiths

Bacterial blacksmiths. Scientists at ISTA forge soft materials from “Lego”-like building blocks with the energy produced by swimming bacteria.

Illustration © ISTA

New Method to Assemble Unconventional Materials.

A hot bath is a place to relax. For scientists, it is also where molecules or tiny building blocks meet to form materials. Researchers at the Institute of Science and Technology Austria (ISTA) take it to the next level and use the energy of swimming bacteria to forge materials. A recent study in Nature Physics shows us how this works and the potential sustainability benefits that may arise from this innovative approach.

You never know when dazzling ideas will strike you. Sometimes they emerge from the most unexpected places, like a boulder gym in Vienna. Such was the case for ISTA’s Daniel Grober, a graduate student in the research group of physicist Jérémie Palacci, who had been working on how to assemble materials leveraging the energy of swimming bacteria, and Mehmet Can Uçar, a postdoc in Edouard Hannezo’s group. Fueled by their shared passion for science and climbing, discussions at the gym turned into a paper-pen model of Grober’s experiment. Their concept captivated Ivan Palaia, a postdoc in Anđela Šarić’s group, who decided to join the task force.

Together, this dynamic all-ISTA trio embarked on a collaborative effort that now reaches its pinnacle with a paper published today in Nature Physics. The study shows a novel experimental strategy to fabricate materials from small building blocks. It translates ideas from metallurgy—the fine art of blacksmithing, where cycles of high temperature and slow cooling set a material’s structure—into soft materials, using the activity from a bath of swimming bacteria.

What are active baths?

In Jérémie Palacci’s research group at the Institute of Science and Technology Austria, it is all about microscopic particles. “Our work revolves around tiny ‘Lego’-like building blocks that are a hundred times smaller than a hair. We try to understand how these components come together and form larger structures,” he explains. Typically, when these building blocks are suspended in water, they jiggle due to temperature, which provides the energy for the particles to hop back and forth randomly. A phenomenon first rationalized by Einstein in 1905 and known as Brownian motion.

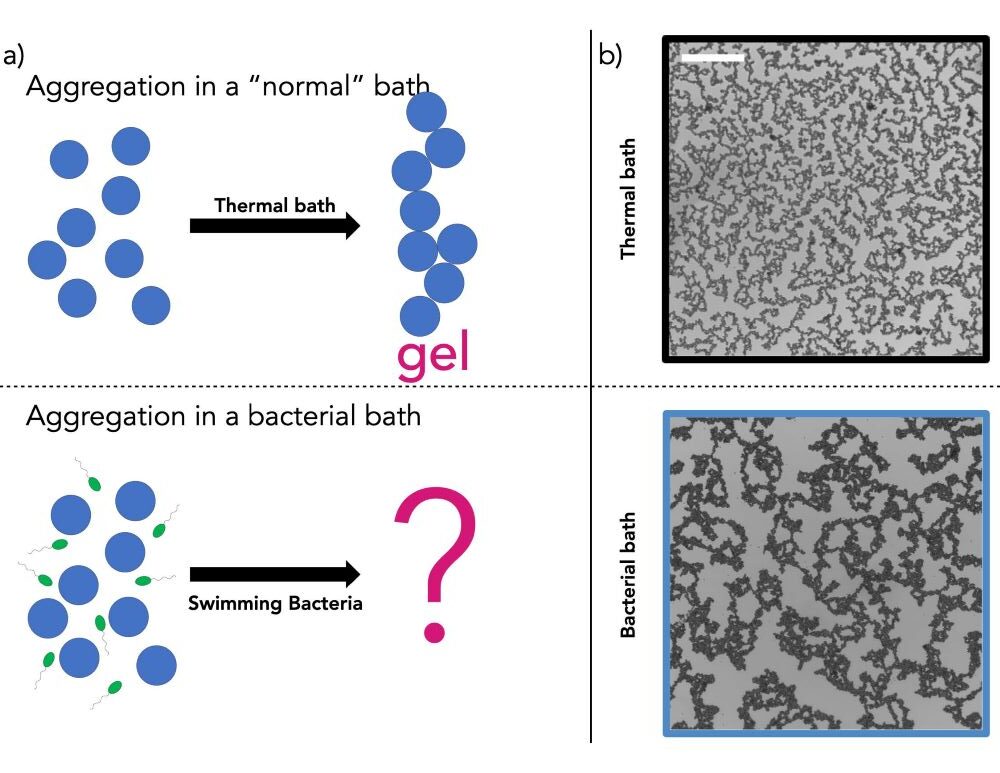

To introduce order amidst the chaos, adding an “active agent” to the water is beneficial. This results in what is known as an “active bath”, where the agent acts like a small fire. In principle, with this extra energy, you can hope to control the assembly and properties of materials—the way the blacksmith forges. However, until now, an approach where for instance bacteria is used to forge, had never been explored.

Bacteria — the fire

Palacci’s student, Daniel Grober, took on this challenge and started to construct such an active bath with characteristics inspired by metallurgy. Grober says, “We used E. coli bacteria as an active agent, as their swimming movement provided energy and some kind of agitation—‘temperature’ for a physicist, equivalent to 2000 °C, similar to the one needed to craft metals. But because it is made by bacteria, and it is not a real oven, it remains gentle enough to be used with gels and soft materials without burning them.” The building blocks were microscopic particles in the form of sticky colloids—round beads that stick together when in contact. This idea proved to be successful. The swimming bacteria effectively amplified the motion of the beads, resulting in the formation of aggregations and gel-like structures.

Dance to the beat of bacteria

Moreover, the observation of these newly formed clusters showed an intriguing singularity. At all times, the aggregates were spinning clockwise, but very slowly. To shed light on this observation, Grober conducted a statistical analysis of the system’s motion. He confirmed a slow and persistent rotation of the aggregates that originates in the clockwise spin (chirality) of the E. coli flagella—the minuscule appendages that propel the bacteria in their movement. The scientist suspected that the rotational motion played a pivotal role in forming the unconventional structures he observed.

Presenting his work in a weekly lab meeting intrigued his colleague Ivan Palaia, which led to the understanding of the phenomenon. Palaia proposed a minimal computational model, to capture the chirality of the bacterial bath without simulating the swimming bacteria. The computer simulations were first validated by quantitatively reproducing the experimental results before providing a deeper understanding of the mechanism. The model confirmed the salient role of the rotation in shaping gels, by forming remarkable structures with exotic mechanical properties that cannot be achieved conventionally.

More to come in the future

This utilization of bacterial baths to assemble unconventional materials holds great promise. For instance, although the study was limited to 2D structures at the micron scale, the approach was designed for its potential in upscaling. “With this innovative approach, it could theoretically be possible to construct 3D samples, large enough to be held in the palm of my hand!” Palacci adds. This advancement could also enhance the sustainability of material production by harnessing energy from bacteria rather than relying on external energy sources.

Finally, the study serves as a proof of concept, laying the foundation for Palacci’s ERC-funded project called “VULCAN: matter powered from within” and underlines once again the significance of interdisciplinary collaboration in science that drives innovation. “The project would have never reached this conceptual and quantitative depth without the collaborative work fostered by ISTA”, Palacci concludes.

Funding information

This project was supported by funding from the US Department of Energy under award DE-SC0019769 to D. Grober & J. Palacci; from the European Union’s Horizon 2020 research and innovation programme under Marie Skłodowska-Curie Grant Agreement No. 101034413 to I. Palaia; from the European Research Council under the European Union’s Horizon 2020 research and innovation programme (Grant No. 802960) to A. Šarić & from the European Union’s Horizon 2020 research and innovation programme under Marie Skłodowska-Curie Grant Agreement No. 754411 to M. C. Ucar.

Originalpublikation:

D. Grober, I. Palaia, M. C. Ucar, E. Hannezo, A. Šarić & J. Palacci. 2023. Unconventional colloidal aggregation in chiral bacterial baths. Nature Physics. DOI: https://doi.org/10.1038/s41567-023-02136-x

Weitere Informationen:

https://ista.ac.at/en/research/palacci-group/

https://ista.ac.at/en/research/hannezo-group/

https://ista.ac.at/en/research/saric-group/

https://ista.ac.at/en/news/four-ista-scientists-awarded-prestigious-erc-consolid…

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…