Bioactive composite supports healing of broken bones

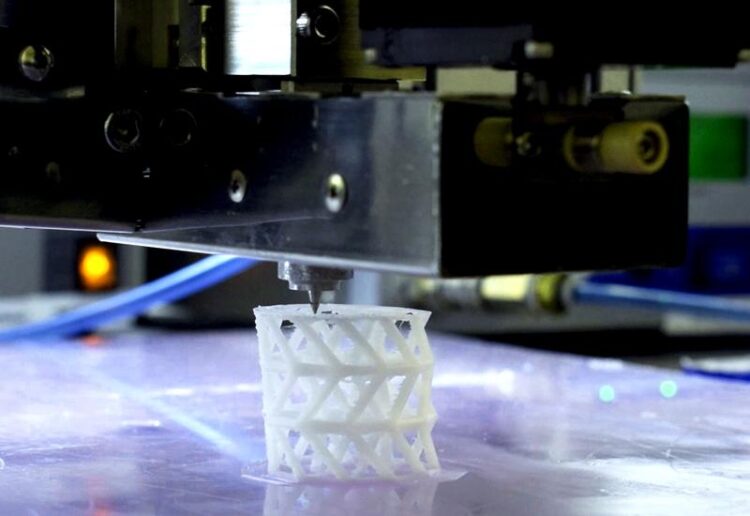

At the pilot plant, a 3D printer builds the scaffold from the composite material.

© BellaSeno

A broken bone failing to heal represents an enormous burden for patients. Fraunhofer researchers have worked alongside partners to develop a composite material to be used in the treatment of such non-union cases. The resulting implant is designed to significantly improve treatment success rates and speed up the healing process. The material is made up of a combination of a biodegradable polymer and bioactive glass and can serve as a main and supporting structure. Its aim is to inhibit the growth of bacteria at the wound site and support the growth of new bone structures. Fraunhofer IFAM will present an demonstrator at the COMPAMED (Hall 8a, Booth G10).

Around 800,000 broken bones are treated in German hospitals each year. For approximately 10 percent of these cases, post-treatment complications occur due to the bone not healing correctly, resulting in painful pseudoarthrosis that makes it impossible to place weight on the bone. For patients, this often means a prolonged stay in hospital with follow-up surgery and long-term treatment, while for clinics, it involves providing time-consuming and expensive therapy.

In order to prevent this from happening, the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Bremen has now provided a solution both elegant and effective through the SCABAEGO (Scaffold Bioactive Glass-Enhanced Osteogenesis) joint research project. The project’s aim is to test the working hypothesis that using bioactive materials in operations supports the healing process and reduces the risk of infection. The institute’s partners for this project are the Department of Trauma and Reconstructive Surgery at the Heidelberg University Hospital as well as BellaSeno, a company specializing in medical engineering based in Leipzig.

The Fraunhofer IFAM researchers have developed a composite material from the biodegradable polymer polycaprolactone (PCL) and bioactive glass. This composite is then used to 3D print customized main and supporting structures for bone fracture sites, called scaffolds. Prior to this, the structure of the damaged bone is mapped using computer tomography (CT). The custom-fit structure replaces the missing part of the bone. It is then filled with bone marrow taken from the iliac crest or from larger long bones. This ensures that the biological bone replacement material (autologous bone craft, ABG) is stably contained and the fracture site heals safely.

Bioactive composite material transforms into bones

The innovative medical product provides even more advantages. “The bioactive glass in the scaffold raises the pH of its surroundings to alkaline. The next thing we want to investigate is the expected result of this, which is inhibiting bacteria growth,” explains Dr. Kai Borcherding, head of the Medical Technology and Life Sciences business unit at Fraunhofer IFAM. The researchers expect this to significantly reduce the risk of postoperative infection.

The bioactive glass also supports the growth of new bone at the fracture site. Because it is in contact with bodily fluids, the glass turns into hydroxylapatite, which is a chemical compound derived primarily from calcium phosphate and a substance very similar to bone. “With bioactive glass, we can tackle the problems that clinics face — we can inhibit bacterial growth and provide effective support for bone healing. After six to seven years, the scaffold will be fully biodegraded and converted into bone,” says PD Dr. Tobias Großner, trauma surgeon and head of experimental trauma surgery at Heidelberg University Hospital.

Bioactive glass is already used for treating bone defects. What’s new is combining it with PCL on an industrial scale. The Fraunhofer researchers have succeeded in binding glass and PCL to create a composite material that can be used directly in additive manufacturing. The main result of this is that customized 3D scaffolds can be produced. It is simple and quick to produce the composite material on an industrial scale. “The PCL polymer is mixed with the glass granulate and a solvent before undergoing multiple processing steps. At the end, the solvent is removed through drying, and the residual composite is finely ground,” explains Borcherding.

Customizable bone support structure

Project partner BellaSeno “prints” the scaffold from this material using a 3D printer. “We use 3D printing so that we can create each scaffold individually to fit the fracture site for each patient,” says Dr. Mohit Chhaya, managing director of BellaSeno and project coordinator. Prior to this, a CT scan of the damaged bone is taken. A 3D virtual image of the bone can then be produced. Using this data, the 3D printer builds a scaffold that perfectly fits the bone. “Every patient receives a unique, tailor-made scaffold. This avoids the time-consuming mechanical fitting and tailoring in the operating theater,” says Großner.

New concept for easy healing

Going above and beyond previous procedures, the innovative composite material should forge significant progress in treatment. The contemporary technique involves covering the fracture site with a bone cement in an initial operation. The human body perceives this cement as a foreign substance and protects itself with a periosteum (bone membrane). This is known as Masquelet’s induced membrane technique. The process can take up to two months. After this period, the patient must undergo surgery again. This time, the surgeon cuts open the periosteum, removes the cement, fills the space with autologous bone and reseals the periosteum. Until now, there have been few options for safely anchoring soft callus and thereby healing fractures without disturbance. When used with a plate or nail, the scaffold provides the soft callus with the required structure until the bone has healed.

The SCABAEGO project research team are already investigating the concept in vitro and in vivo with preclinical tests, working alongside Heidelberg University Hospital. While these are ongoing, the recipe for the composite is being optimized. The proportion of bioactive glass in the scaffold can range between 10 and 30 percent. “We are experimenting with the mixture proportions so that we can leverage the biologically positive characteristics of glass as much as possible while maintaining the core strength of the scaffold,” says Borcherding.

Fraunhofer IFAM will be from November 13 to 16 at the joint Fraunhofer-Gesellschaft booth at the COMPAMED medical engineering trade fair in Düsseldorf, Germany (Hall 8a, Booth G10) presenting an initial 3D-printed demonstrator.

Weitere Informationen:

https://www.fraunhofer.de/en/press/research-news/2023/november-2023/bioactive-co…

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…