Cementless fly ash binder makes concrete 'green'

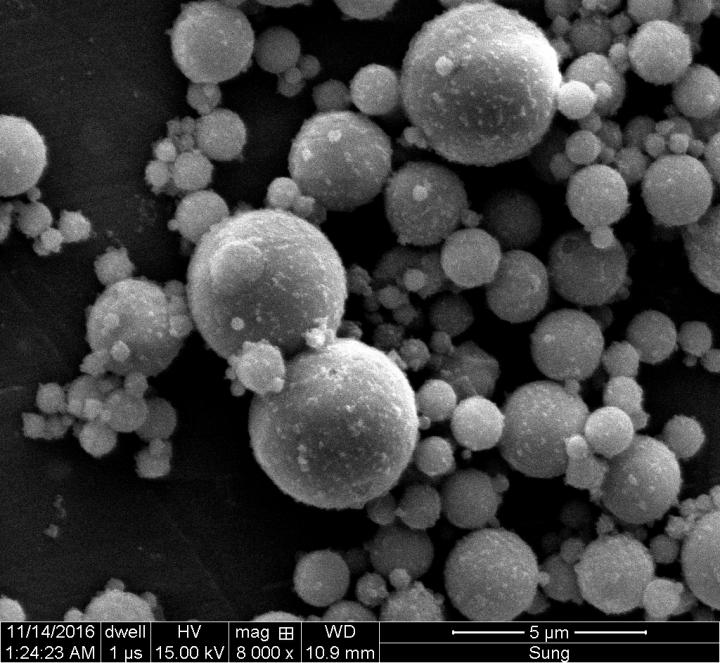

A scanning electron microscope image shows spherical particles in type C fly ash used by Rice University engineers to make cementless binder for concrete. Credit: Multiscale Materials Laboratory/Rice University

Rice University engineers have developed a composite binder made primarily of fly ash, a byproduct of coal-fired power plants, that can replace Portland cement in concrete.

The material is cementless and environmentally friendly, according to Rice materials scientist Rouzbeh Shahsavari, who developed it with graduate student Sung Hoon Hwang.

Fly ash binder does not require the high-temperature processing of Portland cement, yet tests showed it has the same compressive strength after seven days of curing. It also requires only a small fraction of the sodium-based activation chemicals used to harden Portland cement.

The results are reported in the Journal of the American Ceramic Society.

More than 20 billion tons of concrete are produced around the world every year in a manufacturing process that contributes 5 to 10 percent of carbon dioxide to global emissions, surpassed only by transportation and energy as the largest producers of the greenhouse gas.

Manufacturers often use a small amount of silicon- and aluminum-rich fly ash as a supplement to Portland cement in concrete. “The industry typically mixes 5 to 20 percent fly ash into cement to make it green, but a significant portion of the mix is still cement,” said Shahsavari, an assistant professor of civil and environmental engineering and of materials science and nanoengineering.

Previous attempts to entirely replace Portland cement with a fly ash compound required large amounts of expensive sodium-based activators that negate the environmental benefits, he said. “And in the end it was more expensive than cement,” he said.

The researchers used Taguchi analysis, a statistical method developed to narrow the large phase space — all the possible states — of a chemical composition, followed by computational optimization to identify the best mixing strategies.

This greatly improved the structural and mechanical qualities of the synthesized composites, Shahsavari said, and led to an optimal balance of calcium-rich fly ash, nanosilica and calcium oxide with less than 5 percent of a sodium-based activator.

“A majority of past works focused on so-called type F fly ash, which is derived from burning anthracite or bituminous coals in power plants and has low calcium content,” Shahsavari said. “But globally, there are significant sources of lower grade coal such as lignite or sub-bituminous coals. Burning them results in high-calcium, or type C, fly ash, which has been more difficult to activate.

“Our work provides a viable path for efficient and cost-effective activation of this type of high-calcium fly ash, paving the path for the environmentally responsible manufacture of concrete. Future work will assess such properties as long-term behavior, shrinkage and durability.”

Shahsavari suggested the same strategy could be used to turn other industrial waste, such as blast furnace slag and rice hulls, into environmentally friendly cementitious materials without the use of cement.

###

Read the abstract at https:/

This news release can be found online at http://news.

Follow Rice News and Media Relations via Twitter @RiceUNews.

Related materials:

Multiscale Materials Laboratory (Shahsavari): http://rouzbeh.

Rice Department of Civil and Environmental Engineering: https:/

Rice Department of Materials Science and NanoEngineering: https:/

George R. Brown School of Engineering: https:/

Images for download:

http://news.

A scanning electron microscope image shows raw, type C fly ash particles made primarily of calcium oxide as a byproduct of coal-fired power plants. Rice University engineers have made a cementless, environmentally friendly binder for concrete that shows potential to replace Portland cement in many applications. (Credit: Multiscale Materials Laboratory/Rice University)

http://news.

A scanning electron microscope image shows spherical particles in type C fly ash used by Rice University engineers to make cementless binder for concrete. (Credit: Multiscale Materials Laboratory/Rice University)

http://news.

Rouzbeh Shahsavari (Photo by Jeff Fitlow/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,970 undergraduates and 2,934 graduate students, Rice's undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for quality of life and for lots of race/class interaction and No. 2 for happiest students by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger's Personal Finance. To read “What they're saying about Rice,” go to http://tinyurl.

Media Contact

More Information:

http://dx.doi.org/10.1111/jace.15873All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Compact LCOS Microdisplay with Fast CMOS Backplane

…for High-Speed Light Modulation. Researchers from the Fraunhofer Institute for Photonic Microsystems IPMS, in collaboration with HOLOEYE Photonics AG, have developed a compact LCOS microdisplay with high refresh rates that…

New perspectives for material detection

CRC MARIE enters third funding period: A major success for terahertz research: Scientists at the University of Duisburg-Essen and the Ruhr University Bochum have been researching mobile material detection since…

CD Laboratory at TU Graz Researches New Semiconductor Materials

Using energy- and resource-saving methods, a research team at the Institute of Inorganic Chemistry at TU Graz aims to produce high-quality doped silicon layers for the electronics and solar industries….