CVD Diamond Coating: New innovative process improves the adhesion of diamond to cemented carbide

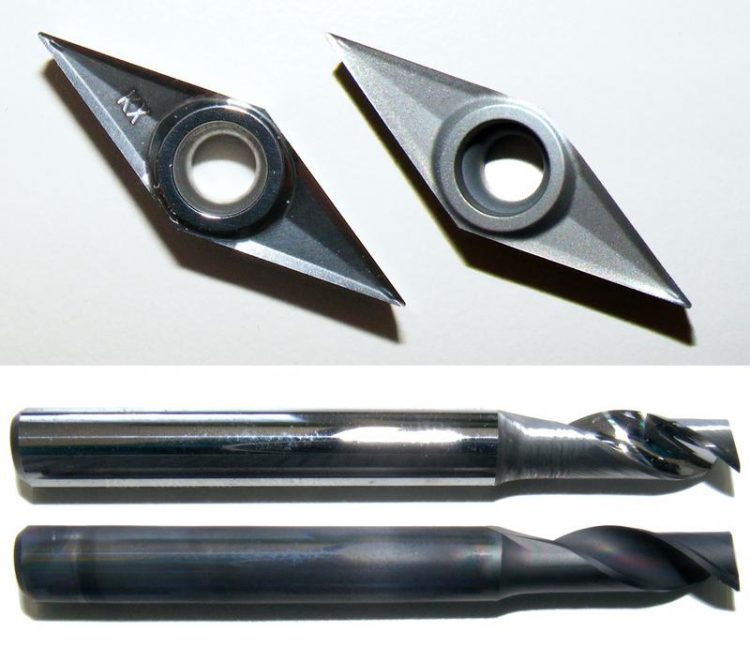

Carbide tools can already be pretreated using the new procedure. Indexable insert (top) and milling cutter (bottom). © Fraunhofer Institute for Mechanics of Materials IWM

Today cemented carbide is the most commonly used material for industrial cutting tools. This is thanks to its combination of tungsten carbide and cobalt. While it is the tungsten carbide that lends this metal its hardness, the toughness that makes it equal to many tasks is provided by the cobalt, which holds the tungsten carbide grains together in the material structure.

Coating the cemented carbide with diamond and thus providing greater hardness is intended to further increase the wear resistance of the tool. 'But this is where the challenge lies, because the cobalt present in the carbide prevents stabilization of the diamond structure during the coating process. Instead, a graphite-like structure of carbon is formed,' says Dr. Manuel Mee, a scientist of the Tribological Coatings group at Fraunhofer IWM.

To prevent the cobalt from interacting with the diamond that is forming or already synthesized, the cobalt phase on the surface of the carbide tool is nowadays removed by means of a wet-chemical process. This type of pretreatment, however, causes the peripheral zone of the carbide to become porous and affects its toughness. The irregular stresses obtained during cutting, particularly when working with inhomogeneous materials such as carbon fiber-reinforced plastics, can result in the breakdown of the now more vulnerable peripheral zone. As a result, the diamond coating flakes off.

Significantly reduced process Duration

'With the new method we can now maintain the stability of the peripheral zone and even slightly increase it', adds Mee. Since he implements every step of the process with a microwave plasma, the process chain need not be interrupted. This eliminates extra work steps and thus valuable time. Another important factor: tools produced by this method can be recycled once they become worn by removing the old coating and applying the process again. This reduces the amount of materials required, which is particularly advantageous in regard to the tungsten used – this is extracted primarily in China and cannot be reliably obtained on the world markets.

Multiple processes combined into one

Apart from the wet-chemical procedure currently used almost exclusively for ensuring the adhesion of diamond to cemented carbide, other methods of surface treatment are possible – and Dr. Mee has bundled these into an integrated process for the functionalization of the tool material. 'By combining different process approaches I have been able to make use of the advantages of each of the factors influencing adhesion while also being able to compensate for their individual disadvantages', he explains. First the carbon is removed from the surface of the carbide at high temperature, which results in the formation of what is known as the eta phase.

Re-enrichment with carbon then leads to a large proportion of the unwanted cobalt in the peripheral zone being vaporized. At the same time, however, the surface structure, hardness and fracture toughness are positively influenced. The process can be controlled in such a way that the eta phase previously created remains in the grain boundaries beneath the surface, and can then be used in the following treatment step to cause a conversion to cobalt tungstate. This has proven itself capable of stabilizing the cobalt and inhibiting its subsequent diffusion. This process step does not, however, prevent a wetting of the surface by a very thin cobalt film. Mee has therefore added a further step to the procedure in which a silicon-based interlayer is added that finally keeps the cobalt away from the diamond layer.

The procedure, which is funded by the 'DiaWerk' project of the Baden-Württemberg Stiftung gGmbH foundation, is meanwhile patent pending and has been described in detail by Mee in his dissertation on microwave plasma-assisted process development for the manufacture of functionally graded hardmetals for CVD diamond coating. For this dissertation Dr. Manuel Mee has been awarded the 2017 Mechanics of Materials Award with its endowment of €3000 by the automotive supplier KSPG AG. This award is given annually by the prize committee of the board of trustees of Fraunhofer IWM to young researchers for outstanding scientific achievement in the field of materials mechanics.

Scientific contact:

Dr. Manuel Mee

Tribological Coatings

Fraunhofer Institute for Mechanics of Materials IWM

Phone +49 761 5142-490

manuel.mee@iwm.fraunhofer.de

http://www.iwm.fraunhofer.de/en/press/press-releases/31_07_2017_processimprovesa… – Website Fraunhofer IWM

http://www.iwm.fraunhofer.de/en/services/tribology/tribological-coatings.html – Tribological Coatings

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…