Keeping the costs of superconducting magnets down using ultrasound

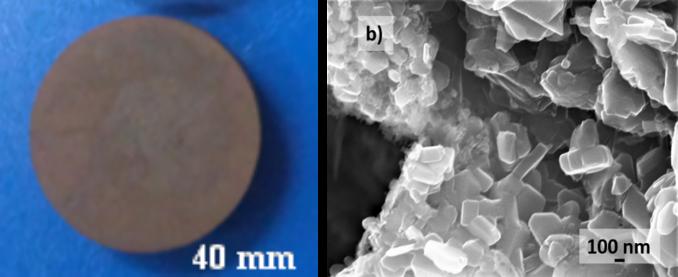

Magnesium diboride is a promising superconducting material with various applications (see fig. on the left). Finding affordable ways to produce improved versions of it is essential. Ultrasonication of magnesium diboride using boron is cheap and scalable and will produce nanometer sized grains (see fig. on the right).

Credit: Shibaura Institute of Technology

Scientists show ultrasonication is a cost-effective approach to enhance the properties of magnesium diboride superconductors.

Superconductivity already has a variety of practical applications, such as medical imaging and levitating transportation like the ever-popular maglev systems. However, to ensure that the benefits of applied superconductors keep spreading further into other technological fields, we need to find ways of not only improving their performance, but also making them more accessible and simpler to fabricate.

In this regard, magnesium diboride (MgB2) has attracted the attention of researchers since its discovery as a superconductor with multiple advantages. It is a lightweight, easily processible material made from widely abundant precursors; these qualities combined, greatly lower the overall cost of working with MgB2.

However, a key practical property of a superconductor is its critical current density (Jc)–the maximum current density at which it can operate without dissipating energy like conventional conductors do. Increasing the Jc of MgB2 through affordable means has proven to be a notable challenge, which is usually tackled through materials engineering and by optimizing fabrication procedures and conditions.

In a recent study accepted for publication in Materials Science and Engineering: B, a team of scientists from Shibaura Institute of Technology, Japan, has developed a cost-effective technique to boost the Jc of bulk MgB2: ultrasonication. Their approach involves dissolving cheap commercial boron in hexane and using ultrasound to disperse the solute thoroughly. Once hexane is evaporated and removed, one obtains a very fine boron powder, which is then sintered with magnesium to produce MgB2. But why does using finer boron result in better superconducting properties?

The answer is magnetic flux pinning. Though superconductors generally repel external magnetic fields, some quantized amounts of magnetic flux sometimes penetrate the material under the right conditions, producing the strong force responsible for superconducting levitation. This penetration occurs only in pinning centers, which arise from various kinds of defects in the material; in the case of MgB2, the pinning centers are located at the grain boundaries. Professor Muralidhar Miryala, who led the study, explains: “To put it briefly, the refined boron powder obtained via ultrasonication results in a higher density of grain boundaries by reducing overall grain size. In turn, the increment in grain boundaries equals an increase in flux pinning centers, which are responsible for the higher Jc we observed in our samples.”

The scientists’ synthesis procedure produced high-quality bulk MgB2 mostly free of oxidation impurities. Compared with a non-ultrasonicated sample used as a reference, the Jc values increased by as much as 20%, depending on the ultrasonication time used. Moreover, the results of scanning electron microscopy and energy dispersive X-ray spectroscopy analyses revealed a secondary mechanism that could give rise to enhanced Jc. The team noted a layered structure of what seems to be Mg-B-O coating the walls of pores of boron deficiencies. This layered coating structure can not only act as a pinning center itself, but also have a restraining effect on the grain size.

Excited about the overall results, Miryala remarks: “Our study lays a foundation towards realizing affordable high-performance bulk MgB2 for superconducting magnets. This will help reduce the cost of magnet-based technologies and make them more accessible to the general population, especially in the medical field.” Even though further studies will be needed to find the optimal solvent and ultrasonication parameters, the present findings are certainly promising and could promote the use of MgB2 superconducting magnets in other areas, including space applications, water cleaning, and electric motors. Hopefully, and given enough time, we shall all benefit from accessible superconductors in one way or another!

###

Reference

Title of original paper: Superconducting properties of sintered bulk MgB2 prepared from hexane-mediated high-energy-ultra-sonicated boron

Journal: Materials Science and Engineering: B

DOI: 10.1016/j.mseb.2020.115030

About Shibaura Institute of Technology (SIT), Japan

Shibaura Institute of Technology (SIT) is a private university with campuses in Tokyo and Saitama. Since the establishment of its predecessor, Tokyo Higher School of Industry and Commerce, in 1927, it has maintained “learning through practice” as its philosophy in the education of engineers. SIT was the only private science and engineering university selected for the Top Global University Project sponsored by the Ministry of Education, Culture, Sports, Science and Technology and will receive support from the ministry for 10 years starting from the 2014 academic year. Its motto, “Nurturing engineers who learn from society and contribute to society,” reflects its mission of fostering scientists and engineers who can contribute to the sustainable growth of the world by exposing their over 8,000 students to culturally diverse environments, where they learn to cope, collaborate, and relate with fellow students from around the world.

Website: https:/

About Professor Muralidhar Miryala from SIT, Japan

Dr Muralidhar Miryala is currently Deputy President and Professor at the Graduate School of Engineering and Science of SIT. His work is mostly centered around superconducting materials, especially the development of powerful superconducting magnets, and understanding and exploiting pinning effects. He has published over 480 research items including patents, books, review articles, research articles etc., between 1990 and 2020.

Funding Information

This work was partly supported by Shibaura Institute of Technology (SIT) Research Center for Green Innovation and Grant-in-Aid FD research budget code: 112282. One of the authors (Sai Srikanth Arvapalli) acknowledges support from SIT for his doctoral program.

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…