Porous crystalline materials: TU Graz researcher shows method for controlled growth

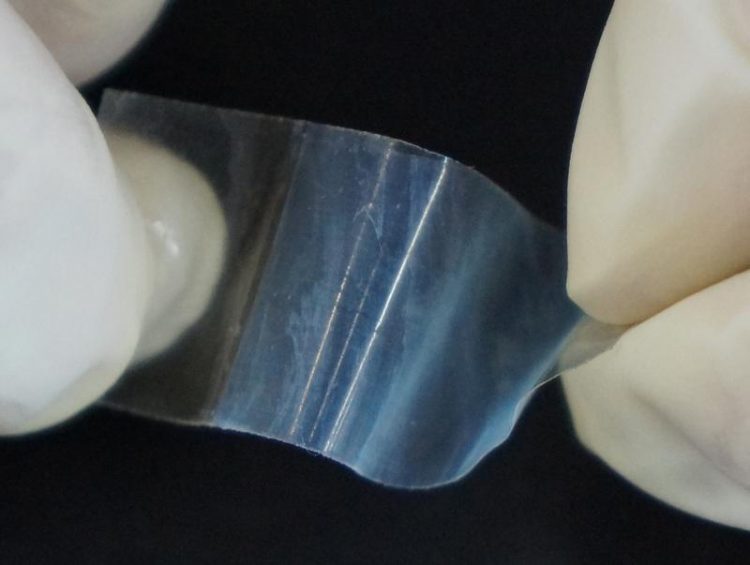

Porous cystalls called MOFs on a comparatively large surface area of one square centimetre. © Nature Materials 2016 Falcaro et.al.

Porous crystals called metal-organic frameworks (MOFs) consist of metallic intersections with organic molecules as connecting elements. Thanks to their high porosity, MOFs have an extremely large surface area. A teaspoonful of MOFs has the same surface area as a football pitch. These countless pores situated in an extremely small space offer room for “guests” and can, for example, be used for gas storage or as “molecular gate” for separation of chemicals.

But MOFs have a much greater potential and it is what Paolo Falcaro from TU Graz’s Institute of Physical and Theoretical Chemistry (PTC) wants to unlock. “MOFs are prepared by self-organisation. We don’t have to do anything other than mix the components, and the crystals will grow by themselves. However, crystals grow with random orientation and position, and thus their pores. Now, we can control this growth, and new properties of MOFs will be explored for multifunctional use in microelectronics, optics, sensors and biotechnology.”

In the current issue of Nature Materials, a research activity lead by Paolo Falcaro and Masahide Takahashi (Osaka Prefecture University – Japan) together with Australian colleagues at the University of Adelaide, Monash University and The Commonwealth Scientific and Industrial Research Organisation (CSIRO) describes a method of growing MOFs on a comparatively large surface area of one square centimetre rapidly achieving an unprecedented controlled orientation and alignment of the crystals.

Directionally dependent properties

The big advantage of precisely oriented crystals in MOFs makes every materials scientist excited. Functional materials can be infiltrated in the pores of the crystals to generate anisotropic materials; in other words, materials with directionally dependent properties. In the journal Nature Materials, the research team shows how the controlled synthesis of a MOF film behaves in the presence of fluorescent dye. Just by rotating the film, the fluorescent signal is turned “on” or “off” and an optically active switch has been created.

Paolo Falcaro: “This has many conceivable applications and we’re going to try many of them with a variety of different functionalities. One and the same material can show different properties through different orientations and alignments. Intentional growth of MOFs on this scale opens up a whole range of promising applications which we’re going to explore step by step.”

Protecting enzymes

A major aim of Paolo Falcaro and his team at TU Graz is the development of MOFs for biotechnological applications: “We are trying to encapsulate enzymes, proteins and even DNA in MOFs and to immunise their activity against fluctuations in temperature. The crystalline structure surrounding the “guest” in the pore has a protective effect, like a tough jacket. We want to check out the possibilities more accurately,” explains Falcaro.

Paolo Falcaro: luminous fingerprints

Born in Padua, Italy, Paolo Falcaro has spent a long time working with the synthesis, fabrication and orientation of porous and crystalline materials, and he publishes his discoveries in prestigious journals. Two years ago, he and colleagues from Australia managed to get invisible fingerprints to glow in UV light by using a drop of liquid with MOF crystals. This new forensic method appears to be fast and broadly applicable providing an alternative method to the previous way for fingerprint detection.

After studies at the Universities of Padua and Bologna and extensive professional experience in Italian commerce, Falcaro moved to the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Australia in 2009. Also, he was visiting professor at the Osaka Prefecture University, Kyoto University in Japan, and currently he is adjunct full professor at the University of Adelaide in Australia. Paolo Falcaro has been Professor of Bio-based Materials Technology at TU Graz’s Faculty of Technical Chemistry, Chemical and Process Engineering,Biotechnology since 1st April, 2016.

Original publication:

Nature Materials | doi 10.1038/nmat4815,

“Centimetre-scale micropore alignment in oriented polycrystalline metal-organic framework films via heteroepitaxial growth”

http://www.nature.com/nmat/journal/vaop/ncurrent/full/nmat4815.html

This research area is anchored in the Field of Expertise “Advanced Materials Science”, one of five research FoE of TU Graz.

Contact:

Paolo FALCARO

Univ.-Prof. Dott. mag. Dr.

TU Graz | Institute of Physical and Theoretical Chemistry

Phone +43 316 873 32203

Mobile: +43 664 8878 3170

E-Mail: paolo.falcaro@tugraz.at

Media Contact

More Information:

http://www.tugraz.atAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…