Warped idea: Ways to stop swayed wood may be around the bend

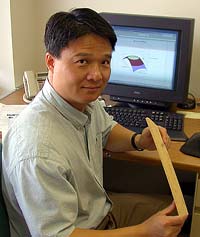

Dr. Zhiyong Cai, Texas Agricultural Experiment Station forest products researcher, is developing a software program that will help manufacturers make wood products that will not warp. (Texas Agricultural Experiment Station photo by Kathleen Phillips) <br>

Anyone who buys a swayed plank of wood has to be, well, warped.

But a Texas forestry sciences researcher may have a straight-forward computer model just around the bend, saving millions for wood manufacturers and consumers.

t

“Wood is an old material that has been used in construction for thousands of years,” said Dr. Zhiyong Cai, Texas Agricultural Experiment Station forest products researcher. “Every place in the world uses wood products, but there still are things we don’t understand such as variability and moisture-related problems such as decay and warping.”

Cai’s study examines a new technique to understand why and how wood for walls, furniture and cabinets warps when moisture gradient is present.

“We have to understand warping in order to solve it and prevent it,” Cai said. “My study aims at giving wood manufacturers good tools with which to make the right decisions in manufacturing.”

According to the Composite Panel Association, warping is a leading technical problem for the industry.

“Severe warping of finished products has the potential to damage a manufacturer’s reputation and significantly increase the cost of making the product,” said Cai, noting that often the wood product leaves a factory looking straight only to warp later.

Warping has been studied for a long time, Cai said, but the existing warping control model for manufacturing composite wood has been one-dimensional and has not been updated in almost 40 years.

“Wood composite panels are two-dimensional and can be regarded as a multi-layered product in which each layer has different behaviors, especially when they experience moisture gradients through their thickness,” Cai said.

His study developed a two-dimensional warping model based on the mechanics of layered composites. Using commercial spreadsheet software and a complicated math formula, wood panels are modeled as having 10 layers with different orientations and properties.

“Once the model has been given input parameters, it will calculate and plot the overall linear expansion and out-of-plane warping of the wood-based panel,” Cai said. That would enable a factory manager to make changes in the manufacturing process to avoid warping of the finished product, he noted.

Cai said the next phase of his research will be to use the computer model in an actual manufacturing setting to see if the model in theory works in practice.

Writer: Kathleen Phillips, (979) 845-2872,ka-phillips@tamu.edu

Contact: Dr. Zhiyong Cai, (979) 458-1417, z-cai@silva.tamu.edu

Media Contact

More Information:

http://agnews.tamu.edu/dailynews/stories/FRSC/Apr1403a.htmAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Future AR/VR controllers could be the palm of your hand

Carnegie Mellon University’s EgoTouch creates simple interfaces for virtual and augmented reality. The new generation of augmented and virtual reality controllers may not just fit in the palm of your…

‘Game changer’ in lithium extraction

Rice researchers develop novel electrochemical reactor. A team of Rice University researchers led by Lisa Biswal and Haotian Wang has developed an innovative electrochemical reactor to extract lithium from natural…

The blue-green sustainable proteins of seaweed

… may soon be on your plate. The protein in sea lettuce, a type of seaweed, is a promising complement to both meat and other current alternative protein sources. Seaweed…