Ribbons of graphene push the material’s potential

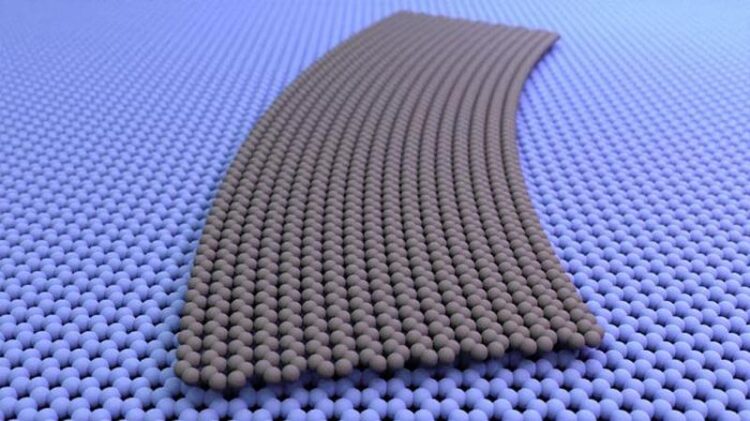

A curved graphene ribbon, illustrated in grey, shown laid flat against another graphene sheet. There is a continuous change in the twist angle between the ribbon above and the sheet below. In some places the atomic lattices of the two sheets line up at a 0° angle to each other, while in others, they are twisted relative to each other by as much as 5°.

Credit: Cory Dean, Columbia University

A new technique developed at Columbia offers a systematic evaluation of twist angle and strain in layered 2D materials.

Think you know everything about a material? Try giving it a twist—literally. That’s the main idea of an emerging field in condensed matter physics called “twistronics,” which has researchers drastically changing the properties of 2D materials, like graphene, with subtle changes—as small as going from a 1.1° to 1.2°—in the angle between stacked layers. Twisted layers of graphene, for example, have been shown to behave in ways that single sheets have not, including acting like magnets, like electrical superconductors, or like a superconductor’s opposite, insulators, all due to small changes in the twist angle between sheets.

In theory, you could dial in any property by turning a knob that changes the twist angle. The reality, however, isn’t so straightforward, says Columbia physicist Cory Dean. Two twisted layers of graphene can become like a new material, but exactly why these different properties manifest is not well understood, let alone something that can be fully controlled yet.

Dean and his lab have come up with a simple new fabrication technique that may help physicists probe the fundamental properties of twisted layers of graphene and other 2D materials in a more systematic and reproducible way. Writing in Science, they use long “ribbons” of graphene, rather than square flakes, to create devices that offer a new level of predictability and control over both twist angle and strain.

Graphene devices have typically been assembled from atom-thin flakes of graphene that are just a few square millimeters. The resulting twist angle between the sheets is fixed in place, and the flakes can be tricky to layer together smoothly. “Imagine graphene as pieces of saran wrap—when you put two pieces together you get random little wrinkles and bubbles,” says postdoc Bjarke Jessen, a co-author on the paper. Those bubbles and wrinkles are akin to changes in the twist angle between the sheets and the physical strain that develops in between and can cause the material to buckle, bend, and pinch randomly. All these variations can yield new behaviors, but they have been difficult to control within and between devices.

Ribbons can help smooth things out. The lab’s new research shows that, with just a little push from the tip of an atomic force microscope, they can bend a graphene ribbon into a stable arc that can then be placed flat on top of a second, uncurved, graphene layer. The result is a continuous variation in the twist angle between the two sheets that spans from 0° to 5° across the length of the device, with evenly distributed strain throughout—no more random bubbles or wrinkles to contend with. “We no longer have to make 10 separate devices with 10 different angles to see what happens,” said postdoc and co-author Maëlle Kapfer. “And, we can now control for strain, which was completely lacking in prior twisted devices.”

The team used special high-resolution microscopes to confirm how uniform their devices were. With that spatial information, they developed a mechanical model that predicts twist angles and strain values simply based on the shape of the curved ribbon.

This first paper was focused on characterizing the behavior and properties of ribbons of graphene as well as other materials that can be thinned to single layers and stacked on top of each other. “It’s worked with every 2D material that we’ve tried so far,” noted Dean. From here, the lab plans to use their new technique to explore how the fundamental properties of quantum materials change as a function of twist angle and strain. For example, prior research has shown that two twisted layers of graphene act like a superconductor when the twist angle is 1.1. However, there are competing models to explain the origins of superconductivity at this so-called “magic angle,” as well as predictions of additional magic angles that have thus far been too difficult to stabilize, Dean said. With devices made with ribbons, which contain all angles between 0° and 5°, the team can more precisely explore the origins of this phenomenon, and others.

“What we are doing is like quantum alchemy: taking a material and turning it into something else. We now have a platform to systematically explore how that happens,” said Jessen.

Read More: Maëlle Kapfer, Bjarke Jessen, et al. Programming twist angle and strain profiles in 2D materials. Science 2023. DOI: 10.1126/science.ade9995

Journal: Science

DOI: 10.1126/science.ade9995

Article Title: Programming twist angle and strain profiles in 2D materials

Article Publication Date: 10-Aug-2023

COI Statement: The authors declare no competing interests.

Media Contact

Ellen Neff

Columbia University

en2505@columbia.edu

Office: 212-853-8048

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…