Rice finds path to nanodiamond from graphene

Rice University researchers have expanded their theory on converting graphene into 2D diamond, or diamane. They have determined that a pinpoint of pressure can trigger connections between layers of graphene, rearranging the lattice into cubic diamond.

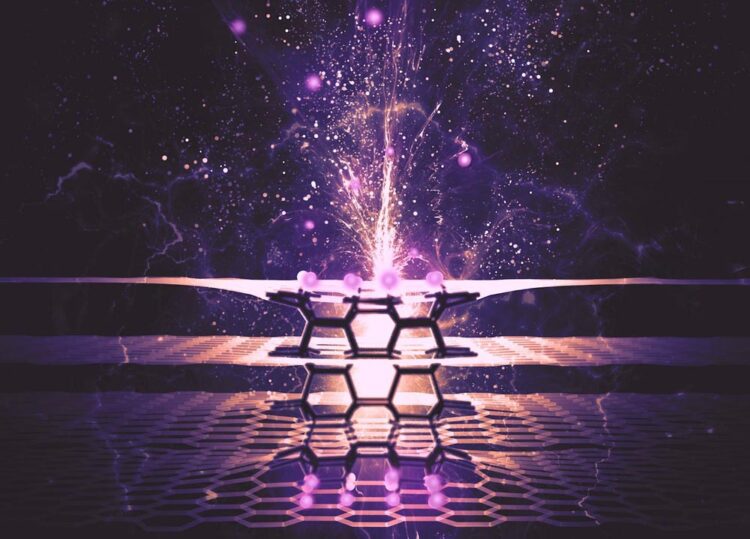

Illustration by Pavel Sorokin

A spot of pressure enables chemical conversion to hardened 2D material.

Marrying two layers of graphene is an easy route to the blissful formation of nanoscale diamond, but sometimes thicker is better.

While it may only take a bit of heat to turn a treated bilayer of the ultrathin material into a cubic lattice of diamane, a bit of pressure in just the right place can convert few-layer graphene as well.

The otherwise chemically driven process is theoretically possible according to scientists at Rice University, who published their most recent thoughts on making high-quality diamane — the 2D form of diamond — in the journal Small.

The research led by materials theorist Boris Yakobson and his colleagues at Rice’s Brown School of Engineering suggests a pinpoint of pressure on few-layer graphene, the atom-thin form of carbon known for its astonishing strength, can nucleate a surface chemical reaction with hydrogen or fluorine.

From there, the diamondlike lattice should propagate throughout the material as atoms of hydrogen or fluorine alight on the top and bottom and covalently bind to the surfaces, prompting carbon-carbon connections between the layers.

The pressure applied to that one spot — as small as a few nanometers – is entirely unnecessary for a bilayer but is needed and must be progressively stronger for thicker films, Yakobson said. Making synthetic diamond from bulk graphite at industrial scale requires about 10-15 gigapascals, or 725,000 pounds per square inch, of pressure.

“Only at the nanoscale — in this case, at nanometer thickness — does it becomes possible for the surface chemistry alone to change the thermodynamics of the crystal, shifting the phase-change point from very high pressure to practically no pressure,” he said.

Single-crystal diamond film for electronics is highly desirable. The material could be used as a hardened insulator or as a heat transducer for cooling nanoelectronics. It could be doped to serve as a wide band gap semiconductor in transistors, or as an element in optical applications.

Yakobson and his colleagues developed a phase diagram in 2014 to show how diamane might be thermodynamically feasible. There’s still no easy way to make it, but the new work adds a critical component the earlier research lacked: a way to overcome the energetic barrier to nucleation that keeps the reaction in check.

“So far only bilayer graphene has been reproducibly converted into diamane, but through sheer chemistry,” Yakobson said. “Combining it with a pinch of local pressure and the mechanochemistry it triggers seems like a promising path to be tried.”

“In thicker films, the barrier rises quickly with the number of layers,” added co-author and former Rice postdoctoral associate Pavel Sorokin. “External pressure can reduce this barrier, but chemistry and pressure must play together to deliver a 2D diamond.”

###

Sergey Erohin, a visiting researcher at Rice and graduate student at the National University of Science and Technology in Moscow, is lead author of the paper. Rice graduate student Qiyuan Ruan is a co-author. Sorokin is a head of laboratory at the Technological Institute for Superhard and Novel Carbon Materials in Moscow. Yakobson is the Karl F. Hasselmann Professor of Materials Science and NanoEngineering and a professor of chemistry at Rice.

The Rice-Army Research Initiative, the Office of Naval Research, and the Ministry of Education and Science of the Russian Federation supported the research.

Read the abstract at https:/

This news release can be found online at https:/

Follow Rice News and Media Relations via Twitter @RiceUNews

Related materials:

Diamond film possible without the pressure: http://news.

Rice tapped by Army for cutting-edge communications research: https:/

Yakobson Research Group: https:/

Rice Department of Materials Science and Nanoengineering: https:/

George R. Brown School of Engineering: https:/

Image for download:

https:/

Rice University researchers have expanded their theory on converting graphene into 2D diamond, or diamane. They have determined that a pinpoint of pressure can trigger connections between layers of graphene, rearranging the lattice into cubic diamond. (Credit: Illustration by Pavel Sorokin)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,978 undergraduates and 3,192 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 1 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Scientists transform blood into regenerative materials

… paving the way for personalized, blood-based, 3D-printed implants. Scientists have created a new ‘biocooperative’ material based on blood, which has shown to successfully repair bones, paving the way for…

A new experimental infection model in flies

…offers a fast and cost-effective way to test drugs. Researchers at the Germans Trias i Pujol Research Institute and Hospital have reinforced their leading role in infectious disease research by…

Material developed with novel stretching properties

KIT researchers produce metamaterial with different extension and compression properties than conventional materials. With this material, the working group headed by Professor Martin Wegener at KIT’s Institute of Applied Physics…