Squeezing a rock-star material could make it stable enough for solar cells

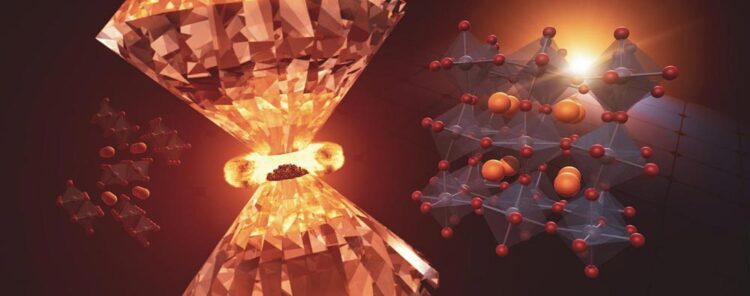

Scientists at SLAC National Accelerator Laboratory and Stanford University discovered that squeezing a promising lead halide material in a diamond anvil cell (left) produces a so-called "black perovskite" (right) that's stable enough for solar power applications.

Credit: Greg Stewart/ SLAC National Accelerator Laboratory

A promising lead halide perovskite is great at converting sunlight to electricity, but it breaks down at room temperature; now scientists have discovered how to stabilize it with pressure from a diamond anvil cell.

Among the materials known as perovskites, one of the most exciting is a material that can convert sunlight to electricity as efficiently as today’s commercial silicon solar cells and has the potential for being much cheaper and easier to manufacture.

There’s just one problem: Of the four possible atomic configurations, or phases, this material can take, three are efficient but unstable at room temperature and in ordinary environments, and they quickly revert to the fourth phase, which is completely useless for solar applications.

Now scientists at Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory have found a novel solution: Simply place the useless version of the material in a diamond anvil cell and squeeze it at high temperature. This treatment nudges its atomic structure into an efficient configuration and keeps it that way, even at room temperature and in relatively moist air.

The researchers described their results in Nature Communications.

“This is the first study to use pressure to control this stability, and it really opens up a lot of possibilities,” said Yu Lin, a SLAC staff scientist and investigator with the Stanford Institute for Materials and Energy Sciences (SIMES).

“Now that we’ve found this optimal way to prepare the material,” she said, “there’s potential for scaling it up for industrial production, and for using this same approach to manipulate other perovskite phases.”

A search for stability

Perovskites get their name from a natural mineral with the same atomic structure. In this case the scientists studied a lead halide perovskite that’s a combination of iodine, lead and cesium.

One phase of this material, known as the yellow phase, does not have a true perovskite structure and can’t be used in solar cells. However, scientists discovered a while back that if you process it in certain ways, it changes to a black perovskite phase that’s extremely efficient at converting sunlight to electricity. “This has made it highly sought after and the focus of a lot of research,” said Stanford Professor and study co-author Wendy Mao.

Unfortunately, these black phases are also structurally unstable and tend to quickly slump back into the useless configuration. Plus, they only operate with high efficiency at high temperatures, Mao said, and researchers will have to overcome both of those problems before they can be used in practical devices.

There had been previous attempts to stabilize the black phases with chemistry, strain or temperature, but only in a moisture-free environment that doesn’t reflect the real-world conditions that solar cells operate in. This study combined both pressure and temperature in a more realistic working environment.

Pressure and heat do the trick

Working with colleagues in the Stanford research groups of Mao and Professor Hemamala Karunadasa, Lin and postdoctoral researcher Feng Ke designed a setup where yellow phase crystals were squeezed between the tips of diamonds in what’s known as a diamond anvil cell. With the pressure still on, the crystals were heated to 450 degrees Celsius and then cooled down.

Under the right combination of pressure and temperature, the crystals turned from yellow to black and stayed in the black phase after the pressure was released, the scientists said. They were resistant to deterioration from moist air and remained stable and efficient at room temperature for 10 to 30 days or more.

Examination with X-rays and other techniques confirmed the shift in the material’s crystal structure, and calculations by SIMES theorists Chunjing Jia and Thomas Devereaux provided insight into how the pressure changed the structure and preserved the black phase.

The pressure needed to turn the crystals black and keep them that way was roughly 1,000 to 6,000 times atmospheric pressure, Lin said - about a tenth of the pressures routinely used in the synthetic diamond industry. So one of the goals for further research will be to transfer what the researchers have learned from their diamond anvil cell experiments to industry and scale up the process to bring it within the realm of manufacturing.

###

Wendy Mao and Hemamala Karunadasa are also SIMES investigators. Parts of this work were performed at the Advanced Photon Source at Argonne National Laboratory and the Advanced Light Source at Lawrence Berkeley National Laboratory. It also used resources of the National Energy Research Scientific Computing Center (NERSC). All three are DOE Office of Science user facilities. Major funding came from the DOE Office of Science.

Citation: Feng Ke et al., Nature Communications, 19 January 2020 (10.1038/s41467-020-20745-5)

SLAC is a vibrant multiprogram laboratory that explores how the universe works at the biggest, smallest and fastest scales and invents powerful tools used by scientists around the globe. With research spanning particle physics, astrophysics and cosmology, materials, chemistry, bio- and energy sciences and scientific computing, we help solve real-world problems and advance the interests of the nation.

SLAC is operated by Stanford University for the U.S. Department of Energy’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time.

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A new class of cosmic X-ray sources discovered

An international team of astronomers, led by researchers from the Astronomical Observatory of the University of Warsaw, have identified a new class of cosmic X-ray sources. The findings have been…

An open solution to improving research reproducibility

Academic and industry scientists collaborate on a new method to characterize research antibodies. Structural Genomics Consortium researchers at The Neuro (Montreal Neurological Institute-Hospital) of McGill University, in collaboration with scientists…

Living in the deep, dark, slow lane

Insights from the first global appraisal of microbiomes in earth’s subsurface environments. Which microbes thrive below us in darkness – in gold mines, in aquifers, in deep boreholes in the…