Energy harvesting: Printed thermoelectric generators for power generation

With the help of newly developed inks and special production techniques, such as origami, inexpensive thermoelectric generators can be produced for various applications.

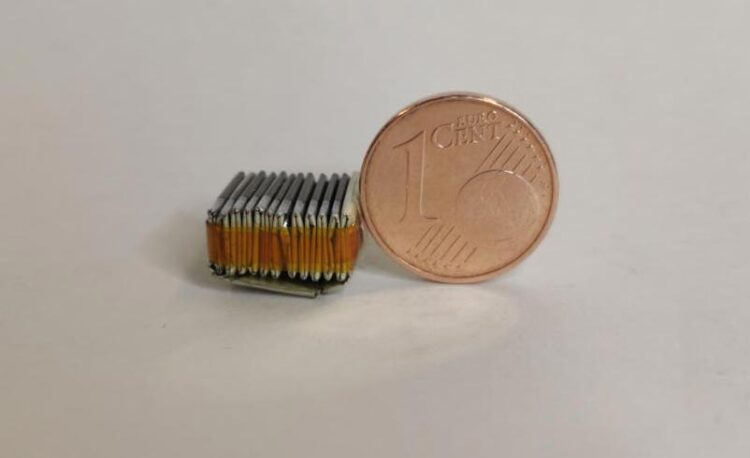

Credit: Andres Rösch, KIT

KIT researchers develop printing process for inexpensive, three-dimensional thermoelectric generators

Thermoelectric generators, TEGs for short, convert ambient heat into electrical power. They enable maintenance-free, environmentally friendly, and autonomous power supply of the continuously growing number of sensors and devices for the Internet of Things (IoT) and recovery of waste heat. Scientists of Karlsruhe Institute of Technology (KIT) have now developed three-dimensional component architectures based on novel, printable thermoelectric materials. This might be a milestone on the way towards use of inexpensive TEGs. The results are reported in npj Flexible Electronics (DOI: 10.1038/s41528-020-00098-1) and ACS Energy Letters (DOI: 10.1021/acsenergylett.0c02159).

“Thermoelectric generators directly convert thermal into electrical energy. This technology enables operation of autonomous sensors for the Internet of Things or in wearables, such as smart watches, fitness trackers, or digital glasses without batteries,” says Professor Uli Lemmer, Head of the Light Technology Institute (LTI) of KIT. In addition, they might be used for the recovery of waste heat in industry and heating systems or in the geothermal energy sector.

New Printing Processes Thanks to Customized Inks

“Conventional TEGs have to be assembled from individual components using relatively complex manufacturing methods,” Lemmer says. “To avoid this, we studied novel printable materials and developed two innovative processes and inks based on organic as well as on inorganic nanoparticles.” These processes and inks can be used to produce inexpensive, three-dimensional printed TEGs.

The first process uses screen printing to apply a 2D pattern onto an ultrathin flexible substrate foil using thermoelectric printing inks. Then, a generator having about the size of a sugar cube is folded by means of an origami technique. This method has been developed jointly by KIT researchers, the Heidelberg Innovation Lab, and a spinoff of KIT. The second process consists in printing a 3D scaffold, to the surfaces of which the thermoelectric ink is applied.

Cost Reduction by Printing Technologies

Lemmer is convinced that scalable production processes, such as roll-to-roll screen printing or modern additive manufacturing (3D printing) are key technologies. “The new production processes not only enable inexpensive scalable production of these TEGs. Printing technologies also allow the component to be adapted to the applications. We are now working on commercializing the printed thermoelectrical system.

###

Research was carried out within the 3DMM2O cluster of excellence and was funded by the German Research Foundation (DFG), the Federal Ministry of Education and Research (BMBF), the MERAGEM Graduate School, and the German Federal Environmental Foundation (DBU).

Original Publications:

Andres Georg Rösch, André Gall, Silas Aslan, Matthias Hecht, Leonard Franke, Md. Mofasser Mallick, Lara Penth, Daniel Bahro, Daniel Friderich, and Ulrich Lemmer: Fully printed origami thermoelectric generators for energy-harvesting. npj Flex Electron 5, 1 (2021).

https:/

Md Mofasser Mallick, Leonard Franke, Andres Georg Rösch, and Uli Lemmer: Shape-Versatile 3D Thermoelectric Generators by Additive Manufacturing. ACS Energy Lett. 6, 85 (2021).

https:/

Press Contact:

Sandra Wiebe,

Press Officer,

Phone: +49 721 608-41172,

sandra.wiebe@kit.edu

Being “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 9,300 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 24,400 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…