Development of MEMS sensor chip equipped with ultra-high quality diamond cantilevers

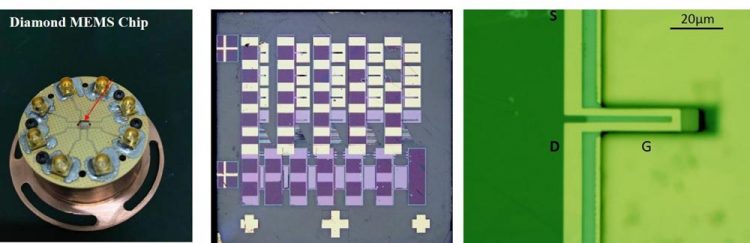

Micrographs of the diamond MEMS chip developed through this research and one of the diamond cantilevers integrated into the chip Credit: NIMS

A NIMS-led research group succeeded in developing a high-quality diamond cantilever with among the highest quality (Q) factor values at room temperature ever achieved.

The group also succeeded for the first time in the world in developing a single crystal diamond microelectromechanical systems (MEMS) sensor chip that can be actuated and sensed by electrical signals.

These achievements may popularize research on diamond MEMS with significantly higher sensitivity and greater reliability than existing silicon MEMS.

MEMS sensors–in which microscopic cantilevers (projecting beams fixed at only one end) and electronic circuits are integrated on a single substrate–have been used in gas sensors, mass analyzers and scanning microscope probes.

For MEMS sensors to be applied in a wider variety of fields, such as disaster prevention and medicine, their sensitivity and reliability need to be further increased.

The elastic constant and mechanical constant of diamond are among the highest of any material, making it promising for use in the development of highly reliable and sensitive MEMS sensors.

However, three-dimensional microfabrication of diamond is difficult due to its mechanical hardness. This research group developed a “smart cut” fabrication method which enabled microprocessing of diamond using ion beams and succeeded in fabricating a single crystal diamond cantilever in 2010.

However, the quality factor of the diamond cantilever was similar to that of existing silicon cantilevers because of the presence of surface defects.

The research group subsequently developed a new technique enabling atomic-scale etching of diamond surfaces. This etching technique allowed the group to remove defects on the bottom surface of the single crystal diamond cantilever fabricated using the smart cut method.

The resulting cantilever exhibited Q factor values–a parameter used to measure the sensitivity of a cantilever–greater than one million; among the world's highest. The group then formulated a novel MEMS device concept: simultaneous integration of a cantilever, an electronic circuit that oscillates the cantilever and an electronic circuit that senses the vibration of the cantilever.

Finally, the group developed a single crystal diamond MEMS chip that can be actuated by electrical signals and successfully demonstrated its operation for the first time in the world. The chip exhibited very high performance; it was highly sensitive and capable of operating at low voltages and at temperatures as high as 600°C.

These results may expedite research on fundamental technology vital to the practical application of diamond MEMS chips and the development of extremely sensitive, high-speed, compact and reliable sensors capable of distinguishing masses differing by as light as a single molecule.

###

This research project was carried out by Meiyong Liao (Principal Researcher, Research Center for Functional Materials [RCFM], NIMS), Haihua Wu (Trainee, RCFM, NIMS), Tokuyuki Teraji (Chief Researcher, RCFM, NIMS), Liwen Sang (Independent Scientist, International Center for Materials Nanoarchitectonics, NIMS), Yasuo Koide (Director of the Research Network and Facility Services Division, NIMS) and Masaya Toda (Associate Professor, Tohoku University). This research was in part supported by the JSPS Grants-in-Aid for Scientific Research (B) (grant number: 15H03999) and the TIA collaborative research program “Kakehashi.” This study was published in Physical Review Materials as an Editors' Suggestion article on September 28, 2018, local time, and in the online version of Advanced Materials Technologies on October 29, 2018, local time.

Contacts

(Regarding this research)

Meiyong Liao,

Principal Researcher,

Research Center for Functional Materials [RCFM],

National Institute for Materials Science

TEL: +81-29-860-4508

E-Mail: Meiyong.Liao@nims.go.jp

(For general inquiries)

Public Relations Office

National Institute for Materials Sciences

Tel: +81-29-859-2026

Fax: +81-29-859-2017

E-Mail: pressrelease@ml.nims.go.jp

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Long-sought structure of powerful anticancer natural product

…solved by integrated approach. A collaborative effort by the research groups of Professor Haruhiko Fuwa from Chuo University and Professor Masashi Tsuda from Kochi University has culminated in the structure…

Making a difference: Efficient water harvesting from air possible

Copolymer solution uses water-loving differential to induce desorption at lower temperatures. Harvesting water from the air and decreasing humidity are crucial to realizing a more comfortable life for humanity. Water-adsorption…

In major materials breakthrough

UVA team solves a nearly 200-year-old challenge in polymers. UVA researchers defy materials science rules with molecules that release stored length to decouple stiffness and stretchability. Researchers at the University…