EU-project SONAR: Better batteries for electricity from renewable energy sources

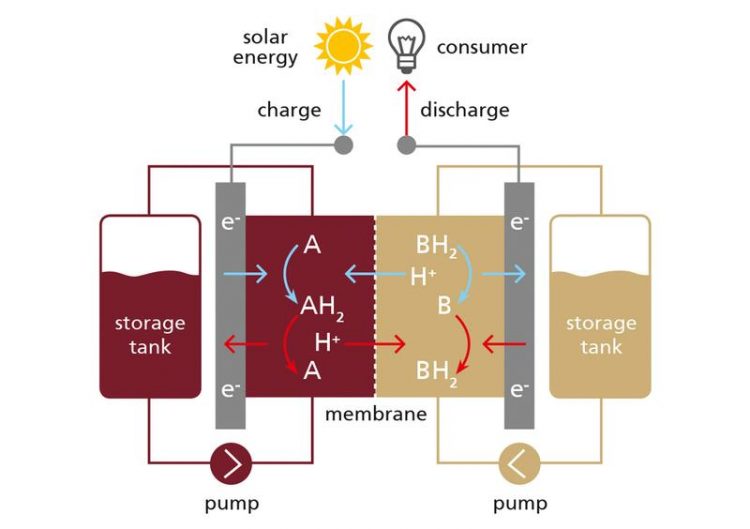

Schematic illustration of a redox flow battery © Fraunhofer SCAI

The benefits of an RFB system depend on many aspects: The perfect, redox-active material should smoothly accept or release electrons, while being soluble, stable, non-toxic and inexpensive.

Moreover, the battery and tank systems should be customized to the specific requirements of the redox material and the site's conditions.

The SONAR project funded by the European Commission aims at capturing the entire development process with all relevant aspects in a digital manner in order to accelerate the screening for suitable substances and the optimization of a battery system's design for specific operating conditions.

The project partners develop tools and workflows for investigating electroactive materials up to whole battery systems. To this end, they combine simulation methods on different physical scales – ranging from the electronic/quantum level to the visible, macroscopic behavior.

Factors such as cost, lifetime and performance are taken into account in order to compare competing energy storage technologies comprehensively.

“To increase screening throughput, SONAR uses intelligent methods of data integration and data analysis, utilizing the growing amount of data generated during the project,” says Dr. Jan Hamaekers, head of the SCAI department Virtual Material Design and exploitation manager in the SONAR project.

“For maximum reliability, we compare the results of simulations and models continuously to experimental data and validate predictions by lab measurements.”

In SONAR, six project partners cooperate with five associated industrial companies. This will ensure the economic relevance of the results. Fraunhofer SCAI uses the models developed independently as well as in a comprehensive screening service to assess the technical and economic potential of a new technology in the early development phase.

This reduces costs, shortens the time to market and thus strengthens the competitiveness of the battery industry in the European Union in the field of organic RFBs.

The project starts as of January 1st 2020 and is to run for four years.

Dr. Jan Hamaekers

Head of Business Area Virtual Material Design

Fraunhofer Institute for Algorithms and Scientific Computing SCAI

53754 Sankt Augustin

E-Mail: jan.hamaekers@scai.fraunhofer.de

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Future of UK Peatlands at Risk From Climate Change

The UK’s peatlands face an uncertain future amid the escalating impacts of climate change Peatlands are critical ecosystems for carbon storage and biodiversity, containing more carbon than all the world’s…

Enhancing Digital Memories Using Noble Gases

The electronics of the future can be made even smaller and more efficient by getting more memory cells to fit in less space. One way to achieve this is by…

TU Graz AI System Boosts E-Mobility Powertrain Development

The new method optimises the technical design with regard to classic objectives such as costs, efficiency and package space requirements and also takes greenhouse gas emissions along the entire supply…