From waste heat to electrical power

The thermomagnetic generators are based on magnetic thin films with highly temperature-dependent properties.

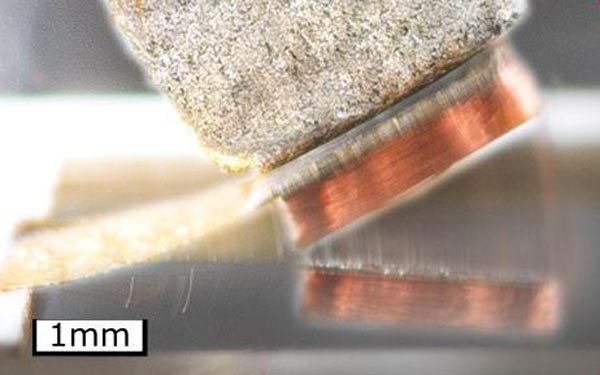

Photo: IMT/KIT

A new generation of thermomagnetic generators

Alloy film thickness and footprint influence electrical power — publication in Joule.

Use of waste heat contributes largely to sustainable energy supply. Scientists of Karlsruhe Institute of Technology (KIT) and Tohoku University in Japan have now come much closer to their goal of converting waste heat into electrical power at small temperature differences. As reported in Joule, electrical power per footprint of thermomagnetic generators based on Heusler alloy films has been increased by a factor of 3.4. (DOI: 10.1016/j.joule.2020.10.019)

Many technical processes only use part of the energy consumed. The remaining fraction leaves the system in the form of waste heat. Frequently, this heat is released into the environment unused. However, it can also be used for heat supply or power generation. The higher the temperature of the waste heat is, the easier and cheaper is its reuse. Thermoelectric generators can use waste heat of low temperature for direct conversion into electrical power. Thermoelectric materials used so far, however, have been expensive and sometimes even toxic. Moreover, thermoelectric generators require large temperature differences for reaching efficiencies of just a few percent.

Thermomagnetic generators represent a promising alternative. They are based on alloys, whose magnetic properties are highly temperature-dependent. Alternating magnetization induces an electrical voltage in a coil applied. Researchers presented first concepts of thermomagnetic generators in the 19th century already. Since then, research has covered a variety of materials. Electrical power, however, has left a lot to be desired.

Scientists of KIT’s Institute of Microstructure Technology (IMT) and Tohoku University in Japan have now succeeded in largely increasing the electrical power per footprint of thermomagnetic generators. “Based on the results of our work, thermomagnetic generators are now competitive with established thermoelectric generators for the first time. With this, we have come a lot closer to the goal of converting waste heat into electrical power at small temperature differences,” says Professor Manfred Kohl, Head of the Smart Materials and Devices Group of IMT. Work of the team is reported in the cover story of the latest issue of Joule.

Vision: Recovery of Waste Heat Close to Room Temperature

So-called Heusler alloys – magnetic intermetallic compounds – are applied in the form of thin films in thermomagnetic generators and provide for a big temperature-dependent change of magnetization and quick heat transfer. This is the basis of the new concept of resonant self-actuation. Even at small temperature differences, resonant vibrations are induced in devices and can be converted efficiently into electrical power. Still, electrical power of single devices is low and upscaling will depend on material development and engineering. The researchers of KIT and Tohoku University used a nickel-manganese-gallium alloy and found that alloy film thickness and the device footprint influence electrical power in opposite directions. Based on this finding, they succeeded in improving electrical power per footprint by a factor of 3.4 by increasing the thickness of the alloy film from five to 40 micrometers. The thermomagnetic generators reached a maximum electrical power of 50 microwatts per square centimeter at a temperature change of just three degrees Celsius. “These results pave the way to the development of customized thermomagnetic generators connected in parallel for potential use of waste heat close to room temperature,” Kohl explains. (or)

###

Original Publication

Joel Joseph, Makoto Ohtsuka, Hiroyuki Miki, and Manfred Kohl: Upscaling of Thermomagnetic Generators Based on Heusler Alloy Films. Joule, 2020. DOI: 10.1016/j.joule.2020.10.019

To the Publication in Joule (Abstract): https://www.cell.com/joule/fulltext/S2542-4351(20)30508-0

More about the KIT Energy Center: https:/

Contact for this press release: Martin Heidelberger, Press Officer, Phone: +49 721 608-41169, martin.heidelberger@kit.edu

Being “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 9,300 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 24,400 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…