Fuel Prices and Environmental Charges Slow down the Speed of Ships

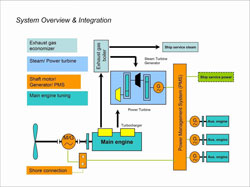

Diagram showing how the energy from a ship\'s exhaust gases is used

Challenged by high energy costs and rising environmental requirements, more and more shipping companies are looking to new propulsion concepts as a solution to their problems. They are now focusing their strategic decisions on saving energy, reducing emissions and optimizing engine size instead of speed.

“Shipping companies are rethinking their position”, explained Ernst-Christoph Krackhardt, who works for Siemens Marine Solutions and is responsible for merchant shipping. “They are deciding in favor of less powerful but more efficient and more cost-effective engines for their ships. To this end, all potential sources of energy such as exhaust gases are being utilized for efficiency increase.”

High fuel prices, investment security, carbon certificate trading and port registration are the issues that are confronting shipping companies and dockyards today and are influencing the construction of new ships. On the one hand, operating costs can be lowered substantially if the speed of a ship is reduced. For example, if a container ship drops its speed from 25 knots to 20 knots, fuel costs fall by up to 40 percent. The engine power needed to propel the ship also falls correspondingly. In future, this will allow for lower-powered engines. “On the other hand”, said Krackhardt, “the solutions developed by Siemens for recovering energy from ships' exhaust gases – waste heat recovery systems – result in a considerable improvement in the energy balance, especially when they are combined with booster drives.” These solutions can be incorporated at the design stage for new ships and can also be retrofitted in existing ships at an acceptable conversion cost. In the case of 8 ships belonging to a Danish shipping company, fuel consumption was reduced by well over ten per cent per ship solely through the use of the ship's exhaust gases to produce electricity. “From a ship's exhaust gases, we generate up to 9 MW of electricity which can be fed into the on-board power system and/or used for the booster drive, an electric motor mounted on the propulsion shaft in order to increase propulsion power”, said Krackhardt.

The way a waste heat recovery system works is to use the energy contained in the hot gases from a ship's diesel engines to produce steam in downstream waste-heat boilers and thus drive turbo-generators that generate energy for the on-board power supply system rather than allow the energy in the exhaust gases to escape into the atmosphere through the ship's funnel. Additional electrical power can also be generated/emitted with the generator/motor which is mounted directly on the propeller shaft. If the output of the main propulsion unit is not being fully utilized, this shaft generator can make electrical energy available to the on-board power supply system, thus placing a greater burden on the main engine. This results in more exhaust-gas energy being generated less expensively, which makes it possible to significantly reduce the operating times of the on-board diesel generator. Moreover, the shaft generator can be used as an electric motor to increase the overall propulsion power of the ship, thus producing a higher speed when necessary. On top of all this, the shaft generator can be used in motoring mode as the sole means of propulsion during maneuvers in harbors or at slow speeds. During these maneuvers, the main propulsion unit (usually a large diesel engine) can even be switched off and uncoupled from the shaft. All the functions are controlled by means of an energy management system which automatically adapts the available energy and operation of the shaft generator/motor to current requirements, while making optimum use of this energy. The waste heat recovery system enables flexible generation and use of electrical energy. The energy management system optimizes the efficiency of the main engine and reduces the operating times of the generator sets and thus their operating and maintenance costs. Dockyards can integrate the waste heat recovery system in order to design a main engine with a lower rating and thus use the engine room more flexibly as the shaft generator is installed in the existing propulsion shaft tunnel and does not therefore require any additional installation space.

Given the current high prices for fuel, Krackhardt calculates that retrofitting a waste heat recovery solution is an investment that pays for itself within a mere two and a half years. “If a ship has a useful life of 25 to 30 years, this is definitely worthwhile – for both ship-owners and the environment. It also creates the option of being able to enhance the carbon trading scenario to the benefit of everyone involved.”

Further information on solutions for merchant shipping and the navy at:

http://www.siemens.com/marine

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of production, transportation and building systems. Integrated hardware and software technologies combined with comprehensive industry-specific solutions enable Siemens to enhance the productivity and efficiency of its customers in industry and infrastructure. The Sector comprises six Divisions: Building Technologies, Industry Automation, Industry Solutions, Mobility, Drive Technologies and Osram. In fiscal 2007 (ended September 30), Siemens Industry generated sales of approximately EUR40 billion (pro forma, unconsolidated) with around 209,000 employees worldwide. http://www.siemens.com/industry With the business activities of Siemens VAI Metal Technologies, (Linz, Austria), Siemens Water Technologies (Warrendale, Pa., U.S.A.), and Industry Technologies, (Erlangen, Germany), the Siemens Industry Solutions Division (Erlangen, Germany) is one of the world's leading solution and service providers for industrial and infrastructure facilities. Using its own products, systems and process technologies, Industry Solutions develops and builds plants for end customers, commissions them and provides support during their entire life cycle.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Time to Leave Home? Revealed Insights into Brood Care of Cichlids

Shell-dwelling cichlids take intense care of their offspring, which they raise in abandoned snail shells. A team at the Max Planck Institute for Biological Intelligence used 3D-printed snail shells to…

Smart Fabrics: Innovative Comfortable Wearable Tech

Researchers have demonstrated new wearable technologies that both generate electricity from human movement and improve the comfort of the technology for the people wearing them. The work stems from an…

Going Steady—Study Reveals North Atlantic’s Gulf Stream Remains Robust

A study by the University of Bern and the Woods Hole Oceanographic Institution in the USA concludes that the ocean circulation in the North Atlantic, which includes the Gulf Stream,…