More reliable operation offshore wind farms

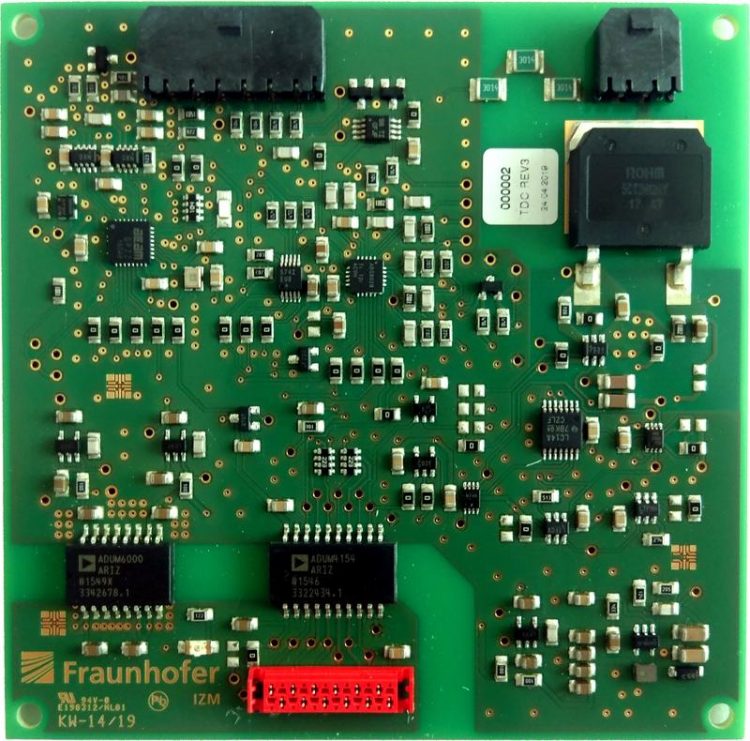

The board developed as part of the AmWind project enables remote, real-time state monitoring for the power modules of offshore wind fars. Fraunhofer IZM

Wind-swept, wet, freezing cold or blazing hot – Wind turbines have to withstand the most extreme climatic conditions on a daily basis, accelerating the aging process for their structural materials and the power electronics installed within them.

For the KorSikA project, the Fraunhofer Institute for Reliability and Microintegration IZM has teamed up with six partners to research the corrosion effects on silver sintering both in isolation and in the realistic context of working modules exposed to watery and salty electrolytes at sea.

Offshore wind farms need to achieve long working lives to realize their entire commercial and environmental potential. At the same time, they are exposed to extremes of humidi-ty, a constant spray of salt water, and the unpredictable weather at sea.

Multiple tests have shown sintering processes to produce more reliable and thermally resilient connec-tions than the current standard technology of soldered layers. An unknown quantity, however, is how the transition to sintered power modules will affect other parameters in offshore wind turbines.

The joint KorSikA project was launched to close this gap, with Fraunhofer IZM exploring aspects of reliability and the technology’s long-term durability. This was made possible by simulating the relevant environmental forces in a realistic, but accelerated setting:

With offshore installations designed for working lives of up to four decades, the usual lifecycle of the power electronics had to be condensed to a period of several weeks. Individual factors, like extreme temperature ranges and the high humidity at sea, were reinforced to expose the sintered modules, constructed to current industry norms as well as different designs, to conditions that can be expected in the field.

The different components were then scrutinized and analyzed to understand their susceptibil-ity to these forces over the entire value chain of the technology.

In a second project stream, the researchers worked with a wind turbine already installed and active to test state monitoring options over the lifecycle of the installed power electronics. Remote monitoring in this way is essential, as it empowers operators to keep an eye on the state of their facilities at any time of the year and in every weather.

The AMWind project produced a concept and developed a component that tracks the state of the power modules by monitoring certain electrical parameters affected by temperatures. This allows a precise forecast of the remaining working life of the power elec-tronics of wind farms in active offshore use. Targeted state monitoring of this nature can help predict or prevent breakdowns in the field.

Preemptive concepts like this are already the established standard for other critical components like transmissions or bearings, but the integrated power electronics as yet lack reliable means for monitoring the technology as it ages. An 8 x 8 cm board is integrated directly in the offshore wind turbine’s power module and surveys several characteristic properties that vary with minute changes in power dissipation, revealing the thermal effects at work on site.

It does so by analyzing certain temperature-dependent electrical signals: the so-called Miller plateau, which determines the time between different voltages during switching. The hardware developed by Fraunhofer IZM records the data with micro-second accuracy to calculate the actual temperature at the module.

The key: The finished driver board is produced specifically for each power module. Once mounted, the micro-controller on it processes the data and passes it directly on to the wind farm operator to help with scheduling maintenance work. This allows a very precise real-time prediction of current stresses, helping keep wind farms working and producing power for longer. More accurate planning reduces the burden of costly maintenance, dangerous repairs at sea, and the slow and expensive supply of spare parts.

The projects reveal the versatility of the reliability tests and real-life use cases made possible by the work of the Fraunhofer IZM’s Environmental and Reliability Engineering professionals. Their expertise in accelerated lifecycle testing, specialized testing methods, materials analysis, and condition monitoring for electronics helps make wind power a leading energy source of the future and brings us closer to a green energy future.

About KorSika:

The KorSikA group project was brought to a successful conclusion in April 2019 after three years of productive work, supported by the Federal Ministry of Education and Research’s “Materials for Resource Efficiency” pro-gram and managed by PtJ as project coordinator. Six partners from science and industry worked under the leadership of Dr. Stefan Wagner: Dr. O.K. Wack Chemie GmbH- Zestron, Danfoss Silicon Power GmbH, Siemens Aktiengesellschaft – Corporate Technology – CT RTC ELE PME-DE, SEMIKRON Elektronik GmbH & Co KG, Heraeus Deutschland GmbH & Co. KG, Forschungs- und Entwicklungszentrum Fachhochschule Kiel GmbH, and the Fraun-hofer Institute for Reliability and Microintegration IZM. Find out more: https://matressource.de/de/projekte/projekte-alphabetisch/korsika/

About AMWind

The project was initiated in November 2016 under the leadership of Felix Wüst and is scheduled to conclude in late January 2020. It is supported by the Federal Ministry of Education and Research and includes Siemens, Infineon Technologies AG, the Technical University of Berlin, WindMW Service GmbH, and M&P as project partners. Find out more: https://www.izm.fraunhofer.de/de/abteilungen/environmental_reliabilityengineerin…

Dr.-Ing. Stefan Wagner l +49 30 46403-609 l stefan.wagner@izm.fraunhofer.de

https://www.izm.fraunhofer.de/en/news_events/tech_news/more-reliable-operation-o…

https://www.izm.fraunhofer.de/en/abteilungen/environmental_reliabilityengineerin…

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…