Multi-functional electrostatic droplet tweezer remotely guides droplet motion

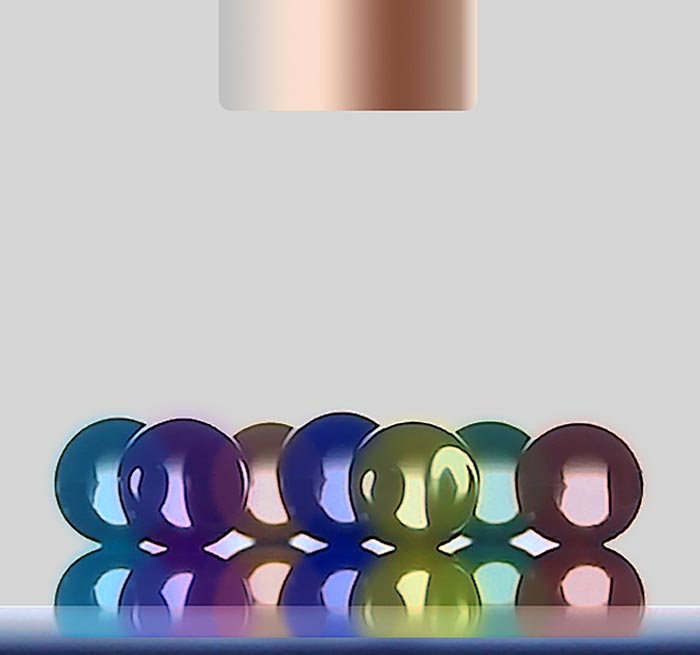

The DEST can move droplets with volume from tens of nanoliters to several millilitres and move droplets in an array.

Credit: Jin Yuankai et al/ DOI number: 10.1073/pnas.2105459119

Droplet manipulation has important applications in areas such as heat management, water harvesting, and chemical reactions. A research team from City University of Hong Kong (CityU) developed a multi-functional electrostatic droplet tweezer that can precisely “trap” liquid droplets and remotely guide their motion on flat and tilted surfaces, and in oil mediums. Experiments showed that the tweezer can manipulate droplets of different volumes and with different components. It has potential applications in areas such as high-throughput biological and chemical analysis.

The research team is led by Professor Wang Zuankai, Chair Professor in CityU’s Department of Mechanical Engineering (MNE). Their findings were published in the academic journal Proceedings of the National Academy of Sciences, under the title “Electrostatic tweezer for droplet manipulation“.

The current approaches to manipulating droplets mainly take advantage of the surface force gradient constructed on the substrates or directly apply external force to the droplets. These methods always require the substrates or droplets to be responsive to external forces. Owing to the deformable nature of droplets, the existing methods for liquid manipulation face many technological challenges, such as short distance, low velocity, restricted operating conditions, and the need to add responsive additives to the droplets.

Manipulating droplets using static electricity

To overcome the above technology constraints, Professor Wang and his team successfully developed a multi-functional droplet electrostatic tweezer that uses electrostatic induction to “attract” and remotely manipulate liquid droplets of different quantities, types and volumes up to a distance of a few centimetres. In short, the tweezer can move the droplets without directly touching them.

Inspired by the electrostatic induction of solid materials, the research team applied electrostatic induction in a liquid to achieve droplet manipulation. Electrostatic induction refers to the redistribution of electric charges in a conductor, caused by the influence of external electric charges. Eventually, the team successfully developed the droplet electrostatic tweezer (DEST) technology, eliminating the need for additives and achieving programmable droplet manipulation without directly contacting the droplets.

The DEST system consists of two parts: a tweezer with an external voltage applied on the electrode tip, and a substrate, which is electrically grounded. Droplets are put on the substrate, and when the the electrostatic tweezer is connected to power, the electric charges of the droplets and substrate are redistributed due to electrostatic induction. This allows the electrostatic tweezer to precisely “trap” the droplets and guide them towards the electrodes at the tip with an appropriate voltage.

“The DEST is programmable,” said Professor Wang. “Our experiments showed that the DEST can guide the movement of the liquid droplets in open spaces, closed channels and even oil. The DEST also allows us to manoeuvre droplets from tens of nanoliters to several millilitres, and different quantities,” said Professor Wang.

Different DEST manipulating modes

The research found that DEST can achieve different modes. For example in the guiding mode, the droplet follows the movement of the tweezer with the electrode on its tip. In the trapping mode, the droplet moves toward the stationary tweezer with the electrode “switched on”. Changing the “on” or “off” state of the electrode of the tweezer allows the droplet to move to or stay at the desired position of the tweezer. When the electrode of a tweezer is “off” but the neighbouring one is “on”, the droplet moves to the “on” tweezer, achieving directional movement.

In the continuous trapping mode of the DEST, since all the electrodes of the tweezer are “on”, the droplet continuously moves to the next “on” tweezer.

Compared to other droplet manipulation technologies, the DEST achieves precise and programmable droplet manipulation with high velocity, unlimited distance, and agile direction steering. The technology offers a potential platform for using droplet manipulation for chemical reactions, such as precipitation reactions and colour reactions. DEST can also be applied to carry small solid objects, and to conduct selective surface cleaning and high-throughput surface enhanced Raman spectroscopy detection.

“We also prepared a superhydrophobic substrate functionalised with silver nanoparticles, so that when the manipulated droplets move on this substrate, they carry the silver nanoparticles. This enhanced the sensitivity in the Raman measurement owing to the plasmonic properties of the silver nanoparticles in the droplets. When one droplet is measured and removed by the electrostatic tweezer, subsequent droplets can be moved to the laser position for another measurement, and the measurement results do not interfere with each other. Another advantage of the DEST in assisting Raman measurement is that it eliminates the need for precise laser focusing on the droplet, thus greatly shortening the measurement time and achieving high-throughput droplet information detection,” explained Dr Jin Yuankai, Postdoc in the MNE and first author of the paper.

“Our technology increased the controllability and broadened the application scenarios of droplet manipulation, and simplified the application process. In addition, the substrates used in our DEST system can be functionalised, enhancing their performance for chemical and biological analysis,” concluded Professor Wang on their research findings.

Professor Wang is the corresponding author of the paper. The first authors are Dr Jin and Dr Xu Wanghuai. Other CityU researchers who participated in the research are Dr Zhang Huanhuan, Dr Sun Jing, Yang Siyan and Dr Liu Minjie, all from the MNE. Other collaborators are from the Institute of Microelectronics, of the Chinese Academy of Sciences.

The research received funding support from CityU, the National Natural Science Foundation of China, the Research Grants Council of Hong Kong, and the Shenzhen Science and Technology Innovation Commission.

Journal: Proceedings of the National Academy of Sciences

DOI: 10.1073/pnas.2105459119

Method of Research: Experimental study

Subject of Research: Not applicable

Article Title: Electrostatic tweezer for droplet manipulation

Article Publication Date: 6-Jan-2022

Media Contact

P.K. Lee

City University of Hong Kong

pikklee@cityu.edu.hk

Office: 852-344-28925

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…