New light source: A million times brighter than the sun

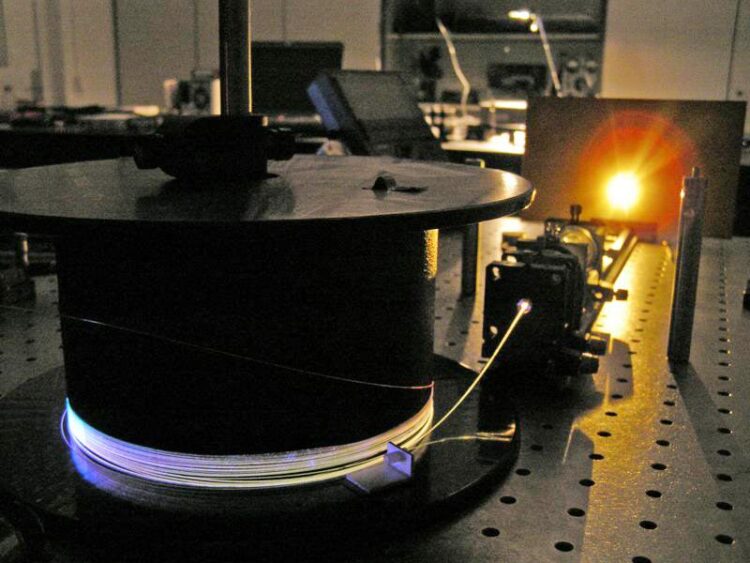

The new laser is one million times brighter than the sun: In this laboratory set-up, it generates a supercontinuum.

© Fraunhofer IWS

PhD thesis investigated application of a special white-light laser for semiconductor industry and microbiology.

A new high-performance white-light laser is expected to speed up quality control in the semiconductor industry and provide closer monitoring of toxicity tests in microbiology. In one step, this laser enables the two-sided characterization of surfaces and can be integrated into production chains. The technology has been developed at the Fraunhofer Application Center for Optical Metrology and Surface Technologies (AZOM) and Westsächsische Hochschule Zwickau (WHZ) as part of a PhD thesis.

© Fraunhofer IWS

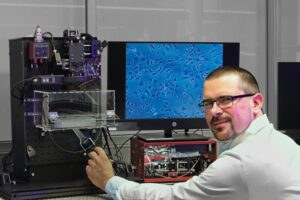

In his PhD thesis, Dr. Tobias Baselt focused on enhancing the optical performance of white-light lasers in metrology. The aim was to minimize costs, time and errors, for example in chip production or microbiology. To this end, the scientist investigated the application of white-light laser sources in two different measurement processes. The result was a new light source – a million times brighter than the sun and can be easily integrated into manufacturing processes – without having to stop them or segregate samples. Today, Baselt heads the Optical Fiber Technology group at Fraunhofer AZOM and is a research associate at the Faculty of Physical Engineering at WHZ. ”In my PhD thesis, I researched the application of specially developed laser sources with white laser light, which are particularly high-performing compared to the current state-of-the art and therefore very promising for microbiological and industrial measurement methods,” he explains.

Quality control in the semiconductor industry and microbiology

Particularly in high-cost manufacturing processes in the semiconductor industry, such as chip production, significant potential savings could thus be achieved. Baselt demonstrated that the white-light laser process can perform quality control of semiconductor elements more quickly. For example, the intensity of the light source can be used to characterize the surface profile, deeper structures and even the reverse side of microchips in a single process. Microbiology could also benefit from the new light source, for example in cell culture studies. In this process, the white-light laser, also known as a supercontinuum source in technical jargon, is focused on the cell for a brief moment. The intensity of this light source permits the imaging of the smallest cell structures without destroying them. With this measurement method, cells can be monitored in real time, allowing early detection of cell changes as well as cell damage. Whereas it was previously only possible to record them at fixed times, Tobias Baselt’s solution makes it possible to record their states non-invasively. This allows close monitoring of the drug impacts, particularly in bioreactors or in toxicity tests. In the next steps, the laboratory results will be further investigated and developed for integration into industrial processes.

About the scientist

In the course of his PhD thesis on “Selected methods for optimization of supercontinuum generation in optical metrology”, Dr. Tobias Baselt published four peer-reviewed papers, three of which he was first author. He presented his results at international conferences in various countries. In addition, he worked on a total of six patents during this time, four of which have already been granted. Since 2015, Mr. Baselt has headed the “Optical Fiber Technologies” group at Fraunhofer AZOM. As a scientist, he has already been researching at Westsächsische Hochschule Zwickau (WHZ) since 2006. He completed the cooperative PhD with WHZ and TU Dresden as “Dr.-Ing.” in September 2021.

About the Fraunhofer Application Center for Optical Metrology and Surface Technologies (AZOM)

The Fraunhofer Institute for Material and Beam Technology IWS operates the Fraunhofer Application Center for Optical Metrology and Surface Technologies (AZOM) in cooperation with Westsächsische Hochschule Zwickau (WHZ). Here, scientists research and develop the latest approaches in optical metrology, image processing, process control and surface characterization. They focus on transferring research results quickly and directly into application-specific solutions for industrial processes. Fraunhofer AZOM provides an interface between applied science and industry in the fields of medical technology, automotive engineering, mechanical engineering and semiconductor technology.

About Westsächsische Hochschule Zwickau (WHZ)

Westächsische Hochschule Zwickau is a university with a focus on technology, economics and quality of life. Around 3,000 students from nearly 50 countries are enrolled in eight faculties with over 50 degree programs. WHZ is particularly successful in applied research. Projects such as the development of augmented reality applications for industrial production, the production of capacitive energy storage devices with extremely high charge carrier density or the development of an automated plug-in system for electromobile public transport combine 120 years of tradition in engineering education with the requirements of the future.

Wissenschaftliche Ansprechpartner:

Dr. Tobias Baselt

Head of Optical Fiber Technology

Fraunhofer Center for Optical Metrology and Surface Technologies

Keplerstraße 2, DE-08056 Zwickau

Phone +49 375 536-1970

tobias.baselt@iws.fraunhofer.de

www.iws.fraunhofer.de

Originalpublikation:

https://www.iws.fraunhofer.de/en/newsandmedia/press_releases/2022/press-release_…

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…