The Future of Oil and Gas: Pumping Innovation in the Oil and Gas Industry

One day fully automated oil and gas fields could become a reality - Siemens is working on the necessary technologies at its development center in Trondheim, Norway

In the space of just a few months, between late 2014 and early 2015, oil prices fell by roughly fifty percent. This happened because more oil reached the market, and partly because demand growth had weakened.

It was not the first time oil prices took a hit. They have always been volatile, but even more so during the past decade, explains Lisa Davis, the member of the Siemens Managing Board who is responsible for Siemens’ Oil & Gas businesses.

Oil’s low price is both a challenge and an opportunity for the industry. Well run oil and gas (O&G) companies that are strong today are likely to emerge even stronger after prices rebound. While the availability of oil fields and associated equipment is always paramount for them, during a slump they have every reason to also focus on cost effective production. Often this means bringing in new technologies and changing processes.

Ingenuity and Sophistication

Lowering production costs is not just an imminent need of the industry. It is also a long-term trend. Most of the “easy oil” has already been extracted – oil that can be produced cheaply because it is onshore, close to the surface, and conveniently spilling out of the ground under high pressure. Other sources, often considered to be “unconventional oil and gas,” require a lot more ingenuity and sophistication to tap.

These include, for example, oil and gas deposits that are deep underground, offshore, or locked in shale or in oil sands. On the whole, it is becoming harder to produce hydrocarbons. But there is also good news: this needn’t make O&G more expensive. We just need to get better at extracting them.

As in the past, technological innovations, as well as more cost-effective processes, will make up for these increased difficulties. What is considered unconventional oil and gas today is likely to become tomorrow’s conventional O&G. In this connection, the following trends are already taking shape:

– Existing fields will run longer and their yield will be increased by injecting water or CO2, which boost the pressure of the reserve.

– Fracking is likely to spread beyond North America.

– Production of heavy oil, e.g. from oil sands, will become more environmentally friendly and less energy-intensive.

– The global market for liquefied natural gas (LNG) is expected to grow robustly. More of the gas that is being flared, and thus wasted, today will be processed and add to market capacity tomorrow.

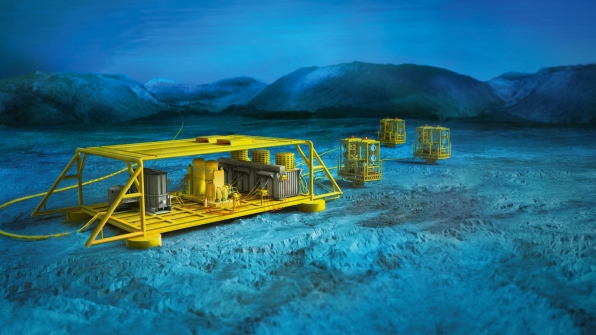

– One day, we will even see automated oil fields at the bottom of the sea, working maintenance-free over decades, at depths of several thousand meters.

At the same time alternatives to O&G are becoming increasingly viable. Electric cars may become more commonplace. And renewable sources, such as wind power, are becoming more economical and could crowd out fossil fuels. According to British Petroleum (BP), four fifths of demand growth is currently attributed to emerging economies. But even their growing appetite for energy may subside at some point.

With less easy oil available and alternatives to oil becoming more viable, the way forward is clear: O&G companies need to reduce production costs. Some are leading the way by bringing more automation to oil fields and by using data in smarter ways. Simply put, in the future more valves will be opened and closed by machines than by people. And it will more often be machines that decide when to open or close valves, not humans. Flying workers to remote offshore locations in helicopters may one day be the exception rather than the rule.

Automated equipment produces data – data that can be mined, aggregated into Big Data and transformed into Smart Data. Analyzing and understanding such production data helps to optimize processes. Here, visualization can be a key tool. Today, 3D visualization software makes it possible for users to immerse themselves in a virtual model of a facility. Indepth training sessions prepare technicians for future challenges.

This is already saving customers real money. For instance, the crew of an offshore platform in Africa was able to begin its training – virtually – while the facility was still under construction. Training sessions in the virtual model reduced the time needed to prepare workers for their tasks, thus helping to put the oil platform into operation more than two months earlier than planned.

Another area that offers opportunities to decrease costs is the replacement of mechanical drives with electrical drives. Today, a turbine often drives pumps and other machines directly, rather than a generator that then produces electricity. Powering equipment electrically instead, allows for energy savings – which in turn helps bring down production costs. So-called aeroderivative turbines can be particularly useful in this area.

Boosting mature fields

So do we need to brace for years of low oil prices? No one knows. But there is one lesson the O&G industry has learned from history. While the price of oil can swing wildly, demand growth can remain surprisingly stable. Over the long term, we have seen price peaks above 140 USD and troughs below 20 USD; but yearly demand growth was between one and two percent over the long run. And more importantly, roughly five percent of existing capacity has to be replaced every year, because of depleting O&G fields. To make up for this, new fields need to be developed and the output of existing fields needs to be boosted, for example through injection of gas.

Automation and digitalization are expected to keep O&G competitive as a form of energy over the course of the next few decades. Whether we like it or not, every year mankind is likely to burn a bit more O&G than the year before. In terms of absolute numbers our demand is growing. In relative terms the importance of O&G may decline over time, as other sources of energy become more important.

That will probably hold true until, one day in the future, it will be permanently more economical to leave the remaining oil in the earth’s crust rather than extracting it. This gradual transition will bring great business opportunities for those who have the courage to innovate and try out new ways to produce and use O&G. “When you look at the growing demand and at the sources of energy we have, it quickly becomes clear that oil and gas will remain crucial for the next few decades at least,“ says Lisa Davis. “We will also need renewables. For the time being we need everything we have. And that includes oil and gas.”

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…