Automated high-throughput sorting of living cells using laser light and AI

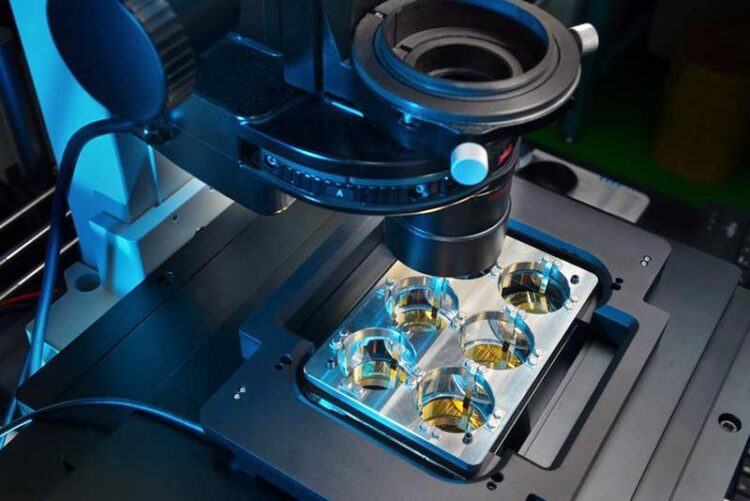

The MIR LIFT process transfers living cells to microtiter plates (MTP) one after the other at a high rate of up to 100 Hz.

© Fraunhofer ILT, Aachen, Germany

Tests on living cell cultures are becoming increasingly important for personalized medicine, drug development and clinical research. The Aachen-based Fraunhofer Institutes for Laser Technology ILT and for Production Technology IPT have developed an AI-assisted high-throughput process that now makes it possible to automatically isolate specific cell types. Using a so-called LIFTOSCOPE, laboratories can localize, identify and analyze dozens of living cells per second in order to transfer them to microtiter plates with laser-induced forward transfer (LIFT).

At analytica 2024 in Munich, the Fraunhofer-Gesellschaft will be presenting the innovative process to the public for the first time in Hall A3, Booth 407.

The LIFTOSCOPE combines high-speed microscopy, AI-based analysis and localization of living cells and cell clusters with laser-induced forward transfer (LIFT). © Fraunhofer ILT, Aachen, Germany

Pluripotent stem cells are the key to personalized medicine. Once they have been isolated from blood and tissue samples, they can be used to grow cell types of different tissues. Since these cultivated cell cultures make it possible to run individual drug and intolerance tests outside the body, they are a powerful tool in selecting highly specific personalized therapies. However, to establish personalized treatment in routine clinical practice, medicine needs efficient methods for isolating pluripotent stem cells. In addition, pharmaceutical research is looking for methods to separate so-called high-producer cells from polyclonal cultures for drug development and to transfer them into monoclonal cultures without impairing cell vitality or the ability to divide. During the pandemic, clinics also had to recognize that the available methods for isolating and analyzing (immune) cells from patient samples are pushing their laboratories to their capacity limits.

The Fraunhofer Institutes for Laser Technology ILT and for Production Technology IPT will be presenting a device at analytica ‘24 – the world’s leading trade fair for laboratory technology, analytics and biotechnology – from April 9 to 12, 2024. Their innovation significantly increases efficiency since it sorts and isolates cells fully automatically. The LIFTOSCOPE integrates an AI-assisted high-throughput process into a commercially available inverted microscope equipped with a high-speed camera and a flash light source. The LIFTOSCOPE combines three high-tech processes in one device to identify cells within microseconds and transfer them to microtiter plates with the high survival rates of over 90 percent.

With AI and lasers to fully automated cell selection

The project team has integrated the patented MIR LIFT process developed at Fraunhofer ILT directly into the microscope’s beam path. A camera system connected to it delivers one hundred high-resolution images per second. The AI developed at Fraunhofer IPT uses semantic segmentation to identify the desired cell types in this image data, and can be trained to recognize pluripotent stem cells, high-producer cells and immune cells. The AI also determines the cells’ exact position and center of gravity. In the MIR LIFT process, they are then transferred one after the other at a high frequency rate of up to 100 Hz onto a microtiter plate in a holder developed at Fraunhofer ILT. “Depending on the cell type, up to 100 percent of all cells survive this procedure,” explains Dr. Nadine Nottrodt, Head of the Biofabrication Group, who is supervising the joint development project at Fraunhofer ILT together with project manager Richard Lensing.

The LIFT process itself is fascinatingly simple. A short nine-nanosecond laser pulse with a few microjoules of pulse energy is enough to stimulate the liquid medium directly under the targeted cell to form a vapor bubble. The cell, which has previously been enzymatically released from its bond, is briefly lifted by the bubble.

As soon as the bubble collapses, suction is formed that flushes the cell into the culture vessel of the microtiter plate. “The cells are randomly distributed in the samples. For this reason, our system follows a predefined grid and transfers cells that are within a radius of 50 micrometers of the focal point,” explains Lensing. There, the LIFTOSCOPE can precisely control and transfer the cells in the high-precision, optically monitored laser process. If required, the LIFT process can also be combined with fluorescent markers to identify specific cells. However, the process works robustly even without additives. There are two reasons for this: On the one hand, the precise localization by the AI ensures that the cells are actually captured by the jet and transported into the microtiter plates. Secondly, Fraunhofer ILT has succeeded in eliminating the metallic absorbers, which were initially required, from the process by continuously developing the LIFT process. As the process uses a mid-infrared laser with a wavelength of 2940 nanometers, the water that is already in the system is now directly excited, while the polymers of the sample carriers do not absorb this wavelength or hardly absorb it at all.

Continuous movement versus stop-and-go process

The project team aims to stabilize the fully automated cell recognition and LIFT process in terms of high throughput and to limit the process time to complete one microtiter plate to ten minutes. This requires high-precision actuators both for imaging and for positioning the laser focus in the process cycle. This ensures that the process reaches the required image resolution for AI-supported cell detection and measurement, on the one hand, and that it precisely allocates and positions the laser focus directly below the cell to within 25 micrometers, on the other. A single cell transfer is completed within 200 microseconds. Within 100 seconds, 10,000 cells can be activated with the LIFTOSCOPE and transferred to the microtiter plates.

The Fraunhofer team pursued two different strategies for moving the cell culture. “In stop-and-go operation, a short rest phase must be inserted before and after the cell LIFT, because each stop triggers hydrodynamic currents in the sample, which must first settle before the next cell can be transferred,” reports Nottrodt. This strategy allows them to sort samples with many different cells, thus reducing the effort required for sample preparation. However, the pauses come at the expense of efficiency. In the continuous process – the second approach – the LIFTOSCOPE scans the sample carriers in a grid of up to 1600 lines with 50 micrometer spacing, depending on the cell type being searched for, and transfers every cell that comes into focus in this continuous movement. The time advantage gained by this method increases the more cells are transferred. Even with 10,000 transferred cells, the continuous process is more than twice as fast, and with 100,000 cells it is already 20 times faster than stop-and-go operation.

The novel, AI- and laser-based process points the way to a fully automated and highly efficient isolation of living cells. According to Nottrodt, the progress of the project to date shows that synchronization of the cell LIFT with the image frequency of the high-speed camera – and thus a single-cell sorting rate of 100 cells per second – is feasible. The next step is to develop the prototype process to reach market maturity. “Interested parties are welcome to visit the Fraunhofer-Gesellschaft’s joint stand in Hall A3/407 at analytica 2024 to get a closer look at the LIFTOSCOPE,” say Nottrodt and Lensing. In view of the potential of personalized medicine, this technology needs to quickly find its way into medical, pharmaceutical and clinical practice.

Wissenschaftliche Ansprechpartner:

Dr. Nadine Nottrodt

Head of Biofabrication Group

Phone +49 241 8906-605

nadine.nottrodt@ilt.fraunhofer.de

Richard Lensing M.Sc.

Biofabrication Group

Phone +49 241 8906-8336

richard.lensing@ilt.fraunhofer.de

Dr. Achim Lenenbach

Head of Department Laser Medical Technology and Biophotonics

Phone +49 241 8906-124

achim.lenenbach@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

www.ilt.fraunhofer.de

Weitere Informationen:

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

New organoid with all key pancreas cells

Researchers from the Organoid group (previously Clevers group) at the Hubrecht Institute have developed a new organoid that mimics the human fetal pancreas, offering a clearer view of its early development….

Unlocking the potential of nickel

New study reveals how to use single atoms to turn CO2 into valuable chemical resources. Nickel and nitrogen co-doped carbon (Ni-N-C) catalysts have shown exceptional performance in converting CO2 into…

‘Spooky action’ at a very short distance

Scientists map out quantum entanglement in protons. Particles streaming from collisions offer insight into dynamic interactions and collective behavior of quarks and gluons. Scientists at the U.S. Department of Energy’s…