Gluing with the Laser

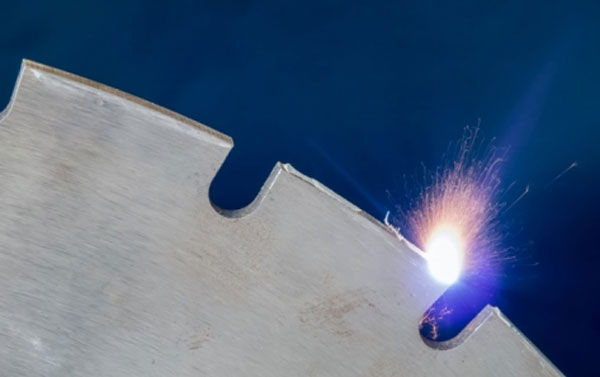

The innovative laser based gluing process could, in the future, replace soldering for refitting saw blades. Photo: LZH

The Laser Zentrum Hannover e.V. (LZH) and the Institut für Werkzeugforschung und Werkstoffe (IFW) in Remscheid have now developed a mobile, laser-based process chain for gluing the cutting segments onto the saw blade and removing them subsequently without causing damage.

Up to now, the soldered cutting segments are thermally detached, the soldering partners prepared, and the new cutting segments are then soldered onto the saw blade.

The thermal stress from soldering leads to axial runout deviations (warpage) and an unfavorable distribution of stress in the saw blade. Consequently, the cutting quality decreases, and cutting losses increase. Therefore, additional process steps are necessary to align and preload the saw blades.

Laser for all the process steps

Based on laser and gluing technology, a laser-based process chain for manufacturing glued saw blades was developed at the LZH and IFW. The laser radiation only exerts minimal thermal stress onto the saw blades, so that in the best case, the blades can be refitted without preloading or alignment. Ideally, the saw blade can be refitted as often as necessary.

The laser-based process for the first and consequent fittings of the saw blade consists of four steps: First, the surfaces of the segments and the saw blade are prepared by structuring them using a pulsed laser system. The segments are then glued onto the saw blade using a one-component epoxy resin adhesive, which is thermally hardened using a continuous wave (cw) laser system.

When the life span of the segments has been reached, they are detached from the saw blade using the cw laser system. A pulsed laser system is then used to remove glue residues and impurities from the gluing partners. Following this, the saw blade can be refitted.

Refitting on the spot

For demonstration purposes, the LZH has developed a mobile unit, with which refitting can be carried out directly at the user’s premises. Such a refitted saw blade has already been used to successfully cut granite.

Advantages of Gluing

In comparison to soldering, gluing has many advantages. Among these are a very low, respectively no thermal distortion, no heat tinting, a homogeneous distribution of stress in the joining zone, and a relatively high joining strength and high vibration dampening.

The IGF project under the number 17120 N of the Forschungsvereinigung Forschungsgemeinschaft Werkzeuge und Werkstoffe e.V. (FGW) [Research Association for Tools and Materials] has been funded within the framework of the program for supporting industrial research of the German Federal Ministry for Economic Affairs and Energy (BMWi), based on a decision of the German Parliament.

A short summary of the research results can be downloaded on the website of the FGW Remscheid or the LZH (only available in German).

The final report can be ordered from the Forschungsgemeinschaft Werkzeuge und Werkstoffe e.V., Papenberger Str. 49, 42859 Remscheid.

http://www.lzh.de/en/publications/pressreleases/2015/gluing-with-the-laser – website of the press release with more pictures, videos and a download link for the summary of the report.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…