Hard-magnetic coatings for high-precision microscopy

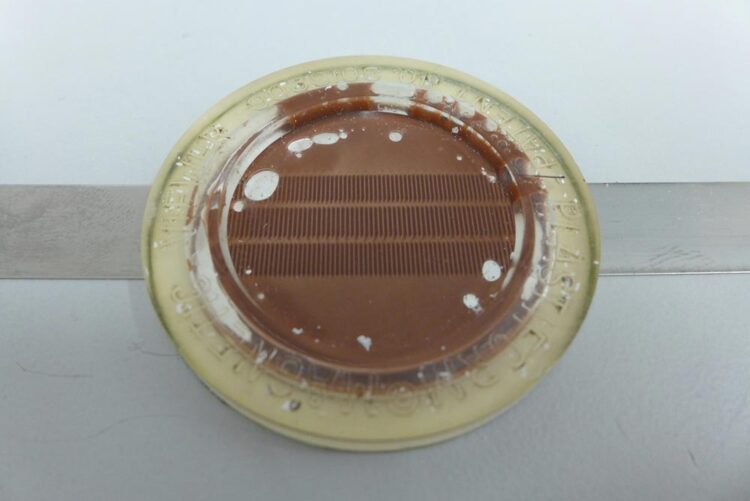

Magnetically coated strip with coding applied.

© ITK Dr. Kassen GmbH

Surface and coating technology

Microscopy is at the forefront of the fight against the coronavirus. Special microscopes, which enable scientists to view minute cell structures, are an indispensable tool in the development of vaccines and new therapies. Such equipment comprises not only a microscope with high optical resolution but also a high-precision microscope stage. Hard-magnetic coatings from the Fraunhofer Institute for Surface Engineering and Thin Films IST also play a key role here. They help enable the examination of minuscule cell structures in precise detail and at great speed.

© ITK Dr. Kassen GmbH

Microscopes and related lab equipment are a vital weapon in the fight against viruses and bacteria. They help scientists in their search for vaccines and therapies to combat, for example, SARS-CoV-2. At Fraunhofer IST in Braunschweig, researchers are developing hard-magnetic cobalt-samarium (CoSm) coatings for magnetic linear scales. These are used in the microscope stages produced by the company ITK Dr. Kassen GmbH. In combination with sensors and an evaluation algorithm, these linear scales enhance the positioning accuracy of the microscope stage, upon which the sample is placed in preparation for viewing.

“Biological material such as cells can move,” explains Dr. Ralf Bandorf, research associate at Fraunhofer IST. “But I still need to be able to steer to the right position with a precision on the micrometer scale.” Microscope stages that use a magnetic positioning system generally have a very compact design. They are used in microscopes from renowned manufacturers such as Leica or Zeiss. The CoSm coatings have been developed in close cooperation with industry partner ITK Dr. Kassen GmbH.

A position resolution on the nanometer scale

Dr. Bandorf and his team apply a CoSm coating to nonmagnetic metal strips. This en-dows the strips with a defined magnetic structure that can be encoded with a signal pattern. In turn, this functional coating can be read by a sensor so as to determine the precise position of a strip. “In combination with the integrated sensors, which read the signals, our coatings enable a position resolution of 5 nanometers,” explains Bandorf, an engineer by training. With their integrated measurement system, the microscope stages are able to determine the precise position of a sample without the need for referencing. A repeatability of plus/minus 100 nanometers can be achieved. This is especially important for the examination of living objects, where the time available for viewing is often limited, and rapid positioning is therefore vital.

CoSm coatings are used in place of galvanized cobalt coatings, production of which requires the use of environmentally harmful chemicals. Robust and durable, they also have very good magnetic properties, which ensures a more powerful magnetic signal than can be realized with cobalt coatings. This signal is strong enough to be measured using a contactless system, which makes such coatings suitable for use in sealed components such as hydraulic cylinders, where optical systems are not an option.

At the same time, CoSm coatings are much less easily demagnetized than pure cobalt coatings and they are unaffected by interference fields. Similarly, very fine layer thick-nesses can be achieved. Furthermore, they can be used for measurements in dirty environments. And they are also suitable for measuring angular positions and radial movements, which is of relevance for robotic applications in, for example, the automotive industry. “If a fine CoSm coating is applied to a component such as a roller bearing, it is then possible to obtain additional information about that component,” Bandorf explains. Demand for high-precision magnetic measurement systems is also growing in the field of electromobility.

Environmentally friendly coating process

The CoSm coatings are created with a process known as hollow-cathode gas flow sputtering, a vacuum deposition method developed at Fraunhofer IST. Unlike galvanization processes, this method does not involve the use of toxic substances.

Weitere Informationen:

https://www.fraunhofer.de/en/press/research-news/2021/january-2021/hard-magnetic…

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…