Harder 3D-printed tools – Researchers from Dresden introduce new process for hardmetal industry

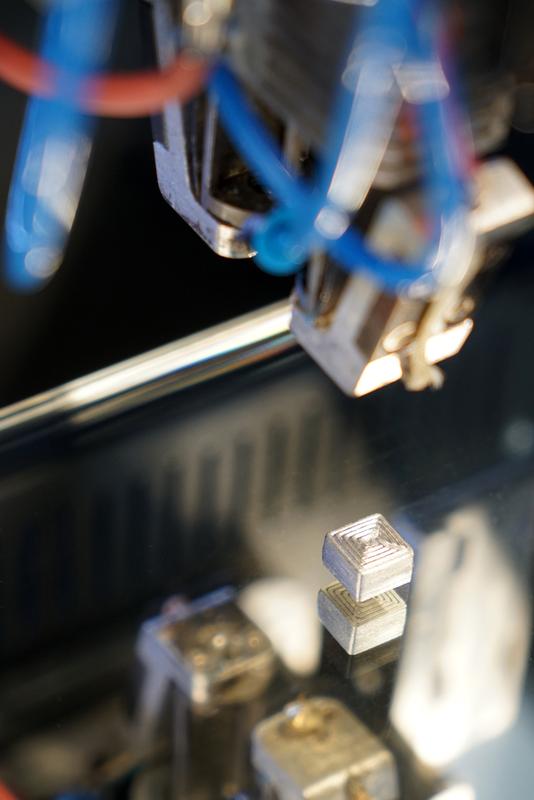

Hardmetal sample with complex geometry on FFF standard printer Hage3D 140 L, in which larger components can be perspectively printed as well.

Additive manufacturing enables complex geometries, but has been limited in terms of hardness and component size so far. Researchers at the Fraunhofer IKTS in Dresden have now adapted the 3D printing process Fused Filament Fabrication for hardmetals. The development meets all requirements for the first time.

Hardmetals consist of the metal binders nickel or cobalt and the hard phase tungsten carbide. Until now, reliable cutting, drilling, pressing and punching tools have been extruded, injection-molded or produced using uniaxial or cold isostatic powder pressing. Complex or specific geometries, however, can only be realized with these processes at great post-processing expenses or not at all.

Additive manufacturing processes provide a solution. Binder jetting and thermoplastic 3D printing have already successfully been used at IKTS with selected hardmetal compositions. However, the metal binder content and the resulting hardness as well as the size of these components are limited.

Fused Filament Fabrication enables economical and individual production of even harder tools for the first time

The additive manufacturing process Fused Filament Fabrication (FFF), which originates from the plastics processing industry, was initially adapted for ceramics and composite materials at IKTS. “The material-efficient FFF also opens up interesting possibilities for the production of large, complex prototypes or special tools made of hardmetals,“ reports IKTS shaping expert Dr. Tassilo Moritz.

During FFF, 3D bodies are manufactured from a flexible, meltable filament. For decades, Fraunhofer IKTS has got a proven powder metallurgical expertise. Thus, it was possible to produce the filament required for the FFF from hardmetal powders with organic binders.

Depending on the materials structure, a reduced grain size and binder content can be used to specifically increase the hardness, compressive and flexural strength of hardmetals. Dr. Johannes Pötschke heads the Hardmetals and Cermets group at IKTS and confirms:

“The filaments can be used as semi-finished products in standard printers and, for the first time, make it possible to print hardmetals with a very low metal binder content of only eight percent and a fine grain size below 0.8 micrometers and thus allow extremely hard components with up to 1700 HV10.“

IKTS supports manufacturers and tooling experts in the selection of suitable materials and in the product-specific further development of 3D printing processes. The development will be presented at EuroPM2018 in Bilbao starting on Monday.

Dr.-Ing. Johannes Pötschke

Phone +49 351 2553-7641

johannes.poetschke@ikts.fraunhofer.de

https://www.ikts.fraunhofer.de/en/press_media/press_releases/2018_10_harder_3D-p…

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

New organoid with all key pancreas cells

Researchers from the Organoid group (previously Clevers group) at the Hubrecht Institute have developed a new organoid that mimics the human fetal pancreas, offering a clearer view of its early development….

Unlocking the potential of nickel

New study reveals how to use single atoms to turn CO2 into valuable chemical resources. Nickel and nitrogen co-doped carbon (Ni-N-C) catalysts have shown exceptional performance in converting CO2 into…

‘Spooky action’ at a very short distance

Scientists map out quantum entanglement in protons. Particles streaming from collisions offer insight into dynamic interactions and collective behavior of quarks and gluons. Scientists at the U.S. Department of Energy’s…