Jelly with memory – predicting the leveling of com-mercial paints

The new procedure enables the flow outcome to be quickly predicted from a paint’s properties, in an au-tomated way and without the need for wasteful paint sample tests. Fraunhofer IPA

The waviness of a coated film represents an important criterion in visual assessment of the coat quality. Improper levelling can lead to a wavy surface displaying an »orange peel« appearance after drying. Ac-cording to figures from the German Paint and Ink Industries Association (Verband der deutschen Lack- und Druckfarbenindustrie), the annual market sales of high quality paints amount to approximately EUR 1.5bn in Germany alone.

Rheological behavior varies during the levelling process

Of all paint characteristics, rheological behavior has the biggest influence on the levelling process. Most industrial uses require paint to be thin enough to be easy to apply, but thick enough that the resulting coat will not run off inclined surfaces. In order to strike a balance between these opposing characteristics, the majority of industrial paints have very complex rheological behavior with shear-sensitive and time-sensitive viscoelastic properties.

The rheological properties of paint can progressively change during the flow process, from thin and watery to a gel-like substance. As the flowing coat of paint is able to »remember« the previ-ous strong shear during application, the rheological properties change, gradually, not suddenly. We call these »memory fluids«.

Levelling predictions for all paints using their properties

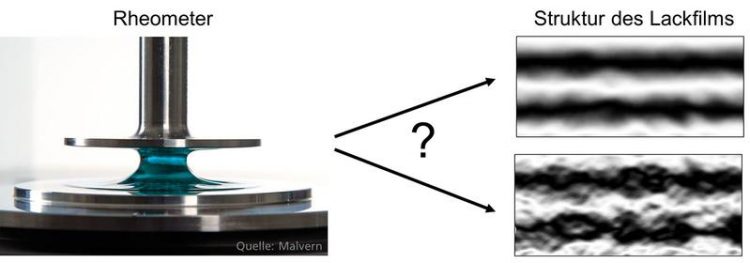

The usual industry methods for measuring rheological behavior do not provide any data that can be used to judge in advance how paint with complex rheological behavior will act. The innovative measurement and evaluation process developed by Fraunhofer IPA means that for the first time, the properties of any paint can be used to predict how fast and how completely it will level. The rheological properties can be meas-ured and translated into a levelling prediction.

Competitive edge for paint development

The levelling process is of particular importance for paint manufacturers, who must optimize the rheological behavior of their paints during paint development. The new procedure expedites paint development by reducing the need for testing samples of paint, and raw materials that will influence the levelling process can be applied in a more targeted way.

While the general practice up until now has been to test paint samples, with half a day’s wait before the paint manufacturer can obtain a levelling outcome, this time can be shortened to just 15 minutes with the new procedure.

Developer Fabian Seeler explains: »From our own experience in paint recipe development, we consider that the total development time of a paint can be shortened by 15%. For an average development time of three years, this means saving 5.4 months, which represents a time advantage that could signify a huge competitive advantage when introducing new car colors, for instance.«

According to an example calcula-tion carried out by Fraunhofer IPA, additional costs averaging EUR 150,000 per paint development could be saved by reducing the need for painting test samples. Fraunhofer IPA will initially offer paint char-acterization using the new procedure as a service. In the second phase, the plan is to also distribute the measurement and evaluation software directly to customers.

Specific ways to make recipe development easier:

- Automatically predict differences in rheological behavior between different recipe variants without painting test samples.

- Levelling outcomes obtained from painted samples can be corroborated using the rheological charac-teristics, which are measured in an innovative way.

- It is possible to derive the rheological properties to achieve a desired surface structure – the levelling process for short and long wavelengths can be tuned in a disered way!

- The new procedure has a higher reproducibility than testing painted samples.

- It is possible to analyze how thixotropic behavior and influence the levelling process – and control them e.g. by use of rheological agents or solvent composition.

Press communication

Jörg-Dieter Walz | Telefon +49 711 970-1667 | presse@ipa.fraunhofer.de

Professional contact

Dr. Oliver Tiedje | Telefon +49 711 970-1773 | oliver.tiedje@ipa.fraunhofer.de

http://www.ipa.fraunhofer.de/de/presse/presseinformationen/wackelpudding-mit-ged…

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…