Laser welding processes for martensitic chromium steels ensure a future safe from collisions

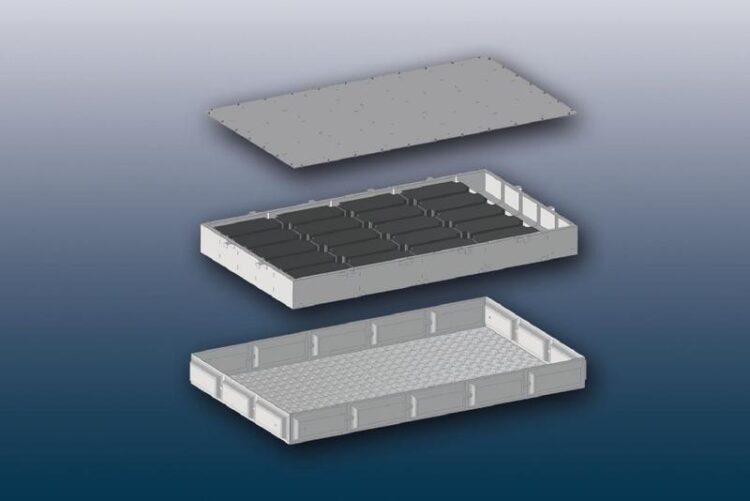

As a demonstration component for the welding and heat treatment of high- and ultra-high-strength steels, Fraunhofer ILT has very lightweight battery boxes with crash frames in the construction and testing phase.

© Fraunhofer ILT, Aachen, Germany

Martensitic chromium steels are one of the steel grades with a future, steels that are ideal for automotive applications since they are both lightweight and corrosion resistant. These materials are particularly in demand for the design of collision-safe battery boxes for electric cars. For this reason, the Fraunhofer Institute for Laser Technology ILT in Aachen uses these sophisticated components as demonstration components for laser welding and heat treatment.

As part of the AiF research project FAAM, supported by FOSTA – Forschungsvereinigung Stahlanwendungen e.V., experts from industry and research took a close look at the current status of those grades: The final online conference in summer 2020 focused on new lightweight construction solutions, joining technology and end face seams, among other things, for martensitic chromium steels.

In detail, the Aachen-based institute investigated how suitable it is to weld a press-hardened chromium steel with martensitic microstructure X46Cr13 (1.4034) in similar and dissimilar joints for assembly applications; this steel is considered difficult to weld due to its high carbon content.

The dissimilar joints were combinations with work-hardened high-manganese steel (1.4678), press-hardened manganese-boron steel (1.5528), high-strength dual-phase steel (1.0944) and cold-rolled fine-grained structural steel (1.0984). Martin Dahmen, in the Macro Joining and Cutting Group at Fraunhofer ILT explains: “The main focus was on the mixing of the different materials, on the metallurgy and the resulting property profiles.”

Better connections thanks to heat treatment

The joining quality can be improved by heat treatment. For this purpose, linear seams of a 1.4034 joint of the same type were heat-treated in the lap joint from 300 to 700 °C outside the process (ex-situ); the seams had to prove their quality in the subsequent shear tensile test.

“At 400 to 500 °C, the highest strengths and lowest hardnesses were obtained,” explains Dahmen. “Remarkable is the high proportion of ductile failure on the fracture surface already at 400 °C.” The researchers aimed at reaching short holding times in order to use laser radiation for heat treatment.

Reactions of dissimilar welds vary

But what do the results look like with dissimilar compounds? Since the tempering behaviors differ, the results vary. Investigations on the combination 1.4034 with dual-phase and fine-grained structural steel showed that a tempering temperature of 400 °C is also best here. The situation is different with other materials: Care should be taken with press-hardened manganese-boron steels as they lose their strength already at 300 °C, whereas this temperature does not affect the 1.4034 to a large extent.

Surface layers improve laser heat treatment

The experimental values serve as a step into the future: heat treatment by laser. In a downstream process with a diode laser, the institute has demonstrated an effective way to temper the weld zone. The measured hardness values showed that temperatures of up to 650 °C can be reached. This corresponds to the maximum temperature at which the material can be tempered without loss of strength.

Laser heat treatment allows selective heat treatment at the lap joint so that only the critical material is processed. The optical properties of the surface can be used specifically for heat treatment. Dahmen describes it accordingly: ”The increased degree of absorption of the weld seam leads to tempering of the weld and the fusion line, while the heat-affected zone experiences less heat input. With an adapted intensity distribution, a significant increase in efficiency is possible.“

Battery boxes demonstrate welding quality

The tests showed that work-hardened austenite and cold-rolled fine-grained structural steel cannot be heat treated by laser. At 400 °C laser tempering worked for the material combination 1.4034/dual phase steel DP980. Fraunhofer ILT intends to use the results to further develop laser-based processes in a future project. These findings should serve as the basis for calculating and designing a battery box with a crash frame fitted to it.

The module carrier consists of a material mix of ultra-high strength and supraductile steels. In the case of the crash frame made of non-work-hardened high-manganese steel, the Aachen-based institute uses the high specific energy absorption to absorb an impact. The high specific energy absorption is due to the formation of twins. Thanks to this combination, the unladen weight of around 70 kg is significantly less than conventional steel battery boxes, which weigh up to 150 kg in an integral design.

Inflating process without tools

The construction and testing will follow shortly: The crash frame will be produced by forming in internal pressure molds. The effect corresponds to that of hydroforming – but without tools and temperature control. Dahmen explains: ”We weld two sheets together in a parallel joint. A pressure medium is used to inflate the component to give it the desired shape.“ The scientist sees good future prospects for more extensive research projects and considers the end face seams to be very promising. Christoph Wendt from Application Technology at Scansonic MI GmbH in Berlin has developed a special laser head for this application and is working intensively on these seams. Dahmen sums up the process’ advantages: ”With this technique, material and, thus, weight could be saved by using narrower flanges.

The research project IFG 19556 N / P1175 “Study on safeguarding welding conditions and on technical design of welded joints in martensitic stainless steels” from the Research Association for steel Application (FOSTA), Düsseldorf, was supported by the Federal Ministry of Economic Affairs and Energy through the German Federation of Industrial Research Associations (AiF) as part of the programme for promoting industrial cooperative research (IGF) on the basis of a decision by the German Bundestag. The project was carried out at the Fraunhofer Institute for Laser Technology ILT in cooperation with Laboratory for material and joining technology of Paderborn University and Research group System Reliability, Adaptive Structures, and Machine Acoustics of Darmstadt Technical University.

Wissenschaftliche Ansprechpartner:

Dipl.-Ing. Martin Dahmen

Group Macro Joining and Cutting

Telephone +49 241 8906-307

martin.dahmen@ilt.fraunhofer.de

Dr. rer. nat. Dirk Petring

Group Leader Macro Joining and Cutting

Telephone +49 241 8906-210

dirk.petring@ilt.fraunhofer.de

Weitere Informationen:

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…