MIT researchers unveil autonomous oil-absorbing robot

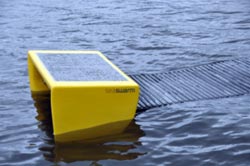

The first Seaswarm prototype was tested in the Charles River in mid-August 2010. The vehicle’s flexible conveyor belt easily adapted to surface waves and the photovoltaic-covered ‘head’ maximized exposure to the sun. Image courtesy of the Senseable City Lab

Using a cutting edge nanotechnology, researchers at MIT have created a robotic prototype that could autonomously navigate the surface of the ocean to collect surface oil and process it on site.

The system, called Seaswarm, is a fleet of vehicles that may make cleaning up future oil spills both less expensive and more efficient than current skimming methods. MIT’s Senseable City Lab will unveil the first Seaswarm prototype at the Venice Biennale's Italian Pavilion on Saturday, August 28. The Venice Biennale is an international art, music and architecture festival whose current theme addresses how nanotechnology will change the way we live in 2050.

The Seaswarm robot uses a conveyor belt covered with a thin nanowire mesh to absorb oil. The fabric, developed by MIT Visiting Associate Professor Francesco Stellacci, and previously featured in a paper published in the journal Nature Nanotechnology, can absorb up to twenty times its own weight in oil while repelling water. By heating up the material, the oil can be removed and burnt locally and the nanofabric can be reused.

“We envisioned something that would move as a 'rolling carpet' along the water and seamlessly absorb a surface spill,” said Senseable City Lab Associate Director Assaf Biderman. “This led to the design of a novel marine vehicle: a simple and lightweight conveyor belt that rolls on the surface of the ocean, adjusting to the waves.”

The Seaswarm robot, which is 16 feet long and seven feet wide, uses two square meters of solar panels for self-propulsion. With just 100 watts, the equivalent of one household light bulb, it could potentially clean continuously for weeks.

By autonomously navigating the water’s surface, Seaswarm proposes a new system for ocean-skimming and oil removal.

Video: Senseable City Lab

Traditional skimmers are attached to large vessels and need to constantly return to the shore for maintenance. Over 800 skimmers were deployed in the Gulf of Mexico during the summer of 2010; however, it is estimated that these skimmers collected only three percent of the surface oil.

“Unlike traditional skimmers, Seaswarm is based on a system of small, autonomous units that behave like a swarm and 'digest' the oil locally while working around the clock without human intervention,” explained Senseable City Lab Director Carlo Ratti.

Using swarm behavior, the units will use wireless communication and GPS and manage their coordinates and ensure an even distribution over a spill site.. By detecting the edge of a spill and moving inward, a single vehicle could clean an entire site autonomously or engage other vehicles for faster cleaning.

“We hope that giant oil spills such as the Deepwater Horizon incident will not occur in the future, however, small oil leaks happen constantly in off shore drilling,” Ratti said. “The brief we gave ourselves was to design a simple, inexpensive cleaning system to address this problem.”

MIT researchers estimate that a fleet of 5,000 Seaswarm robots would be able to clean a spill the size of the gulf in one month. The team has future plans to enter their design into the X-Prize’s $1 million oil-cleanup competition. The award is given to the team that can most efficiently collect surface oil with the highest recovery rate.

Senseable City Lab’s initial Seaswarm prototype will be unveiled at the Venice Biennale’s Italian Pavilion on Saturday, August 28. Visitors will be able to interact with the prototype and view a video on how the vehicle was constructed and how it operates. The Venice Biennale runs from August 29 to November 21, 2010.

The members of Senseable’s Seaswarm team include Luigi Farrauto (Team Leader), Adam Pruden, Carnaven Chiu, Diego Malinoff, Malima Wolf, David Anderson, Sey Min, Rex Britter, Lindsey Hoshaw, Jennifer Dunnam, David Lee, Dietmar Offenhuber, Jan Kokol, Phil Salesses, Matthew Kai Johnson Roberson, Assaf Biderman and Carlo Ratti. The installation at the Venice Biennale was developed in collaboration with Walter Nicolino, Giovanni de Niederhausern, Samuel Colle Dominguez Maldonado, Andrea Cassi, Alberto Bottero and Filipa Carvalho who are part of Walter Nicolino and Carlo Ratti’s architecture office, Carlorattiassociati, in Torino, Italy.

Media Contact

More Information:

http://www.mit.eduAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

You are What You Eat—Stanford Study Links Fiber to Anti-Cancer Gene Modulation

The Fiber Gap: A Growing Concern in American Diets Fiber is well known to be an important part of a healthy diet, yet less than 10% of Americans eat the minimum recommended…

Trust Your Gut—RNA-Protein Discovery for Better Immunity

HIRI researchers uncover control mechanisms of polysaccharide utilization in Bacteroides thetaiotaomicron. Researchers at the Helmholtz Institute for RNA-based Infection Research (HIRI) and the Julius-Maximilians-Universität (JMU) in Würzburg have identified a…

ASXL1 Mutation: The Hidden Trigger Behind Blood Cancers and Inflammation

Scientists show how a mutated gene harms red and white blood cells. LA JOLLA, CA—Scientists at La Jolla Institute for Immunology (LJI) have discovered how a mutated gene kicks off…