Multifunctional tool for antifouling coatings

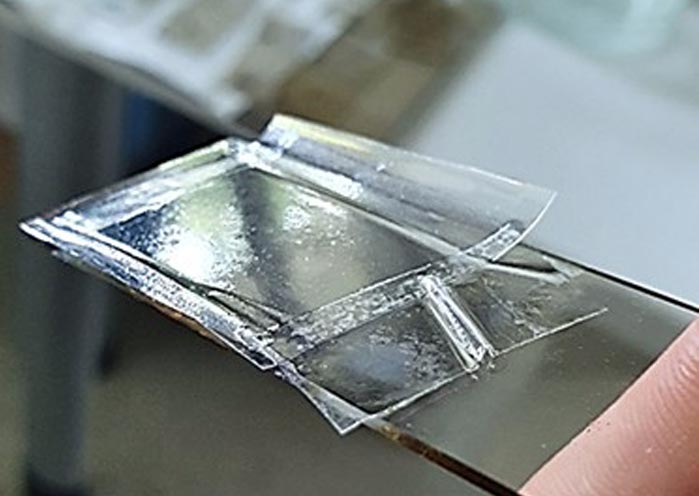

Plastic film with stable anti-adhesive coating, manufactured by the two-stage low-energy ebeam-induced coating process "Ebeam-Grafting"

© Fraunhofer FEP

– Low-energy electron beam.

Electron beam technology can be used to reliably treat and functionalize surfaces. Now the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP has succeeded in producing anti-adhesive coatings on plastic film by applying low-energy-accelerated electrons without the use of additional chemical crosslinkers. The institute will present this topic at BIOEurope 2022, from 24 to 26 October 2022, in Leipzig, at Bio-Saxony booth No. 100, among others.

Antifouling coatings prevent the growth of undesirable organisms on surfaces. This is particularly necessary for shipbuilding, but also important for medical devices and implants.

Low-energy electron beam technology (Ebeam) is a multifunctional tool with a wide range of applications that can be used specifically to modify surfaces. By using low-energy electron beam technology, surfaces can either be gently disinfected or sterilized, materials can be surface-sensitively hardened by crosslinking processes, or surface properties such as wettability can be effectively modulated. Innovative surface-sensitive functionalization technologies guarantee the preservation of material bulk properties while allowing the surface properties to be customized. The use of low accelerating voltages (< 300 kilo-electron volts, keV) in low-energy, non-thermal electron beam processes guarantees very good material compatibility and sustainable material preservation.

What can be done in concrete terms?

Nic Gürtler, PhD candidate in the business unit for Medical and Biotechnological Applications at Fraunhofer FEP explains in detail: “Surface functionalization with accelerated electrons is fast and done without environmentally harmful chemistry. Low-energy accelerated electrons allow chemical bonds close to the surface to be restructured, crosslinked, broken or re-formed. When accelerated electrons collide with a surface, different reactive species such as ions and radicals are formed, which is an important part of surface-specific modification processes. The atmospheric environmental conditions during the electron beam process can be individually adapted to the material and thus influence the desired degree of functionalization. Specifically, we were able to achieve a stable, non-toxic hydrogel coating on hydrophobic polyethylene (PE) and polyethylene terephthalate (PET) films.”

The Ebeam-supported coating process Ebeam-Grafting offers the opportunity to equip materials with selective surface functions so that biocidal, biocompatible or anti-adhesive properties can be achieved, depending on the specific requirement. All process parameters of the non-thermal Ebeam-induced coating process can be individually monitored and modularly adapted. As part of various research projects at Fraunhofer FEP, Ebeam grafting has already been successfully established as a two-step coating process for equipping different hydrophobic plastic surfaces with antifouling attributes. The cell- and protein-repellent surface properties achieved by Ebeam-grafting can be applied in technical industrial sectors or especially in the field of biomaterial research for the development of new medical devices or implants, where uncontrolled biofilm formation is to be prevented. These Ebeam functionalization processes can, for example, help to optimize dental implants in dentistry.

The low-energy electron beam technology and thus also Ebeam-grafting is inline capable, i.e. it can be easily integrated into industrial processes in a customer-specific basis. In order to realize, for example, the modification of large flexible material surfaces, such as packaging, the technology can also be implemented in roll-to-roll systems.

Dr. Ulla König, Head of the Business Unit for Medical and Biotechnological Applications, sums up: “One of the core competencies of Fraunhofer FEP is the development of special low-energy electron beam sources and systems for a wide range of applications. The focus of work is on the technological development of individual customer-specific plant concepts.”

This research was carried out as part of the internal Fraunhofer-funded Discover project “SaveLife”.

Fraunhofer FEP at BioEurope 2022

Biosaxony Pavilion, booth No. 100

24 – 26 October 2022

Leipzig Messe, Messe-Allee 1, Leipzig, Germany

Press contact:

Mrs. Annett Arnold

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

Phone +49 351 2586 333 | presse@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Germany | www.fep.fraunhofer.de

Weitere Informationen:

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…