New aspects of surface wetting revealed

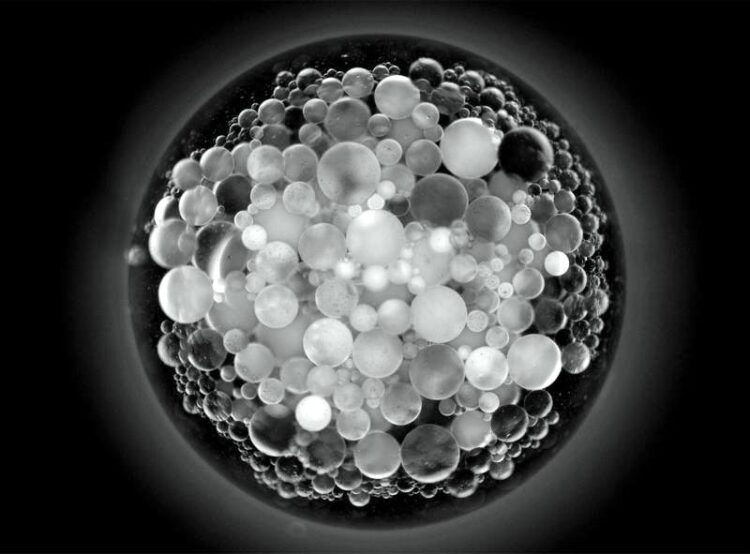

Emulsification during surface wetting affects the spreading of complex liquids on solid surfaces.

Credit: MPI-DS

When a surface is getting wet, also the composition of the liquid plays a role in the wetting process.

Researchers from the Max Planck Institute for Dynamics and Self-Organization (MPI-DS) found that phase separation within the wetting liquid directly affects the dynamics of spreading. Their findings may be important in various applications, including tissue engineering, biology and semiconductor manufacturing. The study was recently published in the scientific journal PNAS.

During phase separation, liquid mixtures of several components turn into an emulsion, an effect commonly known from the Greek liqueur Ouzo, which turns pale when adding water. Moreover, this process occurs in many other different contexts, such as cloud formation in the sky or biomolecular condensation within biological cells. Usually, phase separation requires contact with solid particles because wetting their surfaces lowers the required energy.

The researchers from the MPI-DS around Stefan Karpitschka now found that not only wetting drives phase separation, but also phase separation drives wetting. Usually, classical forces such as gravity or capillarity cause liquid spreading. However, also phase separation actively drives the wetting of the surface, sometimes even much faster. “This technically allows to manipulate thin films of complex liquids on surfaces, for example during manufacturing processes involving the phase change,” explains Stefan Karpitschka, group leader at the MPI-DS.

Phase separation affects liquid spreading

To reveal the impact of phase separation on liquid spreading, the researchers studied droplets of liquid mixtures on solid surfaces. Youchuang Chao, leading author the study describes the key results: “We observed an unexpected spreading phenomenon compared to the well-established spreading laws for single-component liquids. Phase separation occurs close to the edge of the droplet, which allows to direct liquid components to this specific area, thereby controlling chemical processes.” These novel findings evidence the strong coupling between the dynamical wetting and phase separation, even at the molecular-scale level.

The new insights of the study may thus enable developing new strategies for surface processing. These include oil recovery from surfaces as well as applications in manufacturing in the microchips and semiconductor industry.

Wissenschaftliche Ansprechpartner:

Dr. Stefan Karpitschka

Originalpublikation:

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…