New priming method improves battery life, efficiency

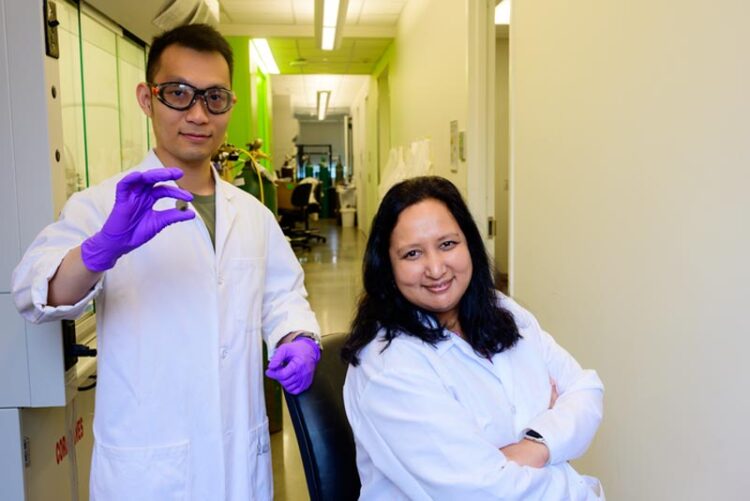

Quan Nguyen (left), Sibani Lisa Biswal and collaborators developed a prelithiation technique that helps improve the performance of lithium-ion batteries with silicon anodes.

Photo by Jeff Fitlow/Rice University

Rice U. engineers improve prelithiation, uncover lithium-trapping mechanism.

Silicon anode batteries have the potential to revolutionize energy storage capabilities, which is key to meeting climate goals and unlocking the full potential of electric vehicles.

However, the irreversible depletion of lithium ions in silicon anodes puts a major constraint on the development of next-generation lithium-ion batteries.

Scientists at Rice University’s George R. Brown School of Engineering have developed a readily scalable method to optimize prelithiation, a process that helps mitigate lithium loss and improves battery life cycles by coating silicon anodes with stabilized lithium metal particles (SLMPs).

The Rice lab of chemical and biomolecular engineer Sibani Lisa Biswal found that spray-coating the anodes with a mixture of the particles and a surfactant improves battery life by 22% to 44%. Battery cells with a greater amount of the coating initially achieved a higher stability and cycle life. However, there was a drawback: When cycled at full capacity, a larger amount of the particle coating led to more lithium trapping, causing the battery to fade more rapidly in subsequent cycles.

The study is published in ACS Applied Energy Materials.

Replacing graphite with silicon in lithium-ion batteries would significantly improve their energy density ⎯ the amount of energy stored relative to weight and size ⎯ because graphite, which is made of carbon, can pack fewer lithium ions than silicon. It takes six carbon atoms for every single lithium ion, while just one silicon atom can bond with as many as four lithium ions.

“Silicon is one of those materials that has the capability to really improve the energy density for the anode side of lithium-ion batteries,” Biswal said. “That’s why there’s currently this push in battery science to replace graphite anodes with silicon ones.”

However, silicon has other properties that present challenges.

“One of the major problems with silicon is that it continually forms what we call a solid-electrolyte interphase or SEI layer that actually consumes lithium,” Biswal said.

The layer is formed when the electrolyte in a battery cell reacts with electrons and lithium ions, resulting in a nanometer-scale layer of salts deposited on the anode. Once formed, the layer insulates the electrolyte from the anode, preventing the reaction from continuing. However, the SEI can break throughout the subsequent charge and discharge cycles, and, as it reforms, it irreversibly depletes the battery’s lithium reserve even further.

“The volume of a silicon anode will vary as the battery is being cycled, which can break the SEI or otherwise make it unstable,” said Quan Nguyen, a chemical and biomolecular engineering doctoral alum and lead author on the study. “We want this layer to remain stable throughout the battery’s later charge and discharge cycles.”

The prelithiation method developed by Biswal and her team improves SEI layer stability, which means fewer lithium ions are depleted when it is formed.

“Prelithiation is a strategy designed to compensate for the lithium loss that typically occurs with silicon,” Biswal said. “You can think of it in terms of priming a surface, like when you’re painting a wall and you need to first apply an undercoat to make sure your paint sticks. Prelithiation allows us to ‘prime’ the anodes so batteries can have a much more stable, longer cycle life.”

While these particles and prelithiation are not new, the Biswal lab was able to improve the process in a way that is readily incorporated into existing battery manufacturing processes.

“One aspect of the process that is definitely new and that Quan developed was the use of a surfactant to help disperse the particles,” Biswal said. “This has not been reported before, and it’s what allows you to have an even dispersion. So instead of them clumping up or building up into different pockets within the battery, they can be uniformly distributed.”

Nguyen explained that mixing the particles with a solvent without the surfactant will not result in a uniform coating. Moreover, spray-coating proved better at achieving an even distribution than other methods of application onto anodes.

“The spray-coating method is compatible with large-scale manufacturing,” Nguyen said.

Controlling the cycling capacity of the cell is crucial to the process.

“If you do not control the capacity at which you cycle the cell, a higher amount of particles will trigger this lithium-trapping mechanism we discovered and described in the paper,” Nguyen said. “But if you cycle the cell with an even distribution of the coating, then lithium trapping won’t happen.

“If we find ways to avoid lithium trapping by optimizing cycling strategies and the SLMP amount, that would allow us to better exploit the higher energy density of silicon-based anodes.”

Biswal is Rice’s William M. McCardell Professor in Chemical Engineering, a professor of materials science and nanoengineering, and associate dean for faculty development.

The research was supported by Ford Motor Co.’s University Research Program, the National Science Foundation (1842494, CBET-1626418) and the Shared Equipment Authority at Rice.

This release can be found online at news.rice.edu.

Follow Rice News and Media Relations via Twitter @RiceUNews.

Peer-reviewed paper:

Prelithiation Effects in Enhancing Silicon-Based Anodes for Full-Cell Lithium-Ion Batteries Using Stabilized Lithium Metal Particles | ACS Applied Energy Materials | DOI: 10.1021/acsaem.3c00713

Authors: Quan Anh Nguyen, Anulekha K. Haridas, Tanguy Terlier and Sibani Lisa Biswal

https://doi.org/10.1021/acsaem.3c00713

Image downloads:

https://news-network.rice.edu/news/files/2023/05/JWF_0765_1_LG.jpg

CAPTION: Quan Nguyen (left), Sibani Lisa Biswal and collaborators developed a prelithiation technique that helps improve the performance of lithium-ion batteries with silicon anodes. (Photo by Jeff Fitlow/Rice University)

https://news-network.rice.edu/news/files/2023/05/JWF_0695_2_LG.jpg

CAPTION: Quan Nguyen is a chemical and biomolecular engineering doctoral alum and lead author on the study. (Photo by Jeff Fitlow/Rice University)

https://news-network.rice.edu/news/files/2023/05/JWF_0724_3_LG.jpg

CAPTION: Quan Nguyen (left) and Sibani Lisa Biswal. (Photo by Jeff Fitlow/Rice University)

https://news-network.rice.edu/news/files/2023/05/JWF_0752_4_LG.jpg

CAPTION: Quan Nguyen holds one of the batteries assembled using the prelithiation protocol described in the study. (Photo by Jeff Fitlow/Rice University)

Related stories:

NSF backs Biswal to devise nanofluids for reducing use of dangerous solvents:

https://chbe.rice.edu/news/nsf-backs-biswal-devise-nanofluids-reducing-use-dangerous-solvents

Grain boundaries go with the flow:

https://news.rice.edu/news/2022/grain-boundaries-go-flow

Brushing thin films onto electrodes preserves batteries:

https://news.rice.edu/news/2022/brushing-thin-films-electrodes-preserves-batteries

Links:

Biswal Research Group: https://www.ruf.rice.edu/~biswalab/Biswal_Research_Group/Welcome.html

Chemical and Biomolecular Engineering: https://chbe.rice.edu

George R. Brown School of Engineering: https://engineering.rice.edu

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 4,552 undergraduates and 3,998 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 4 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

If you do not wish to receive news releases from Rice University, reply to this email and write “unsubscribe” in the subject line. Office of News and Media Relations – MS 300, Rice University, 6100 Main St., Houston, TX 77005.

Journal: ACS Applied Energy Materials

DOI: 10.1021/acsaem.3c00713

Method of Research: Experimental study

Subject of Research: Not applicable

Article Title: Prelithiation Effects in Enhancing Silicon-Based Anodes for Full-Cell Lithium-Ion Batteries Using Stabilized Lithium Metal Particles

Article Publication Date: 1-May-2023

COI Statement: The authors declare no competing financial interest.

Media Contact

Silvia Cernea Clark

Rice University

silviacc@rice.edu

Office: 7133486728

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…