This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Researchers master self-assembly of novel nanodots

Using pulsed lasers, researchers have coaxed the metal nickel to self-assemble into arrays of nanodots – each spot a mere seven nanometers (seven billionths of a meter) across – one-tenth the diameter of existing nanodots.

Because the method works with a variety of materials and may drastically reduce imperfections, the new procedure may also bolster research into extremely hard materials and efforts to develop ultra-dens

Want a tennis racket that propels balls faster than a race car or a sturdy ship hull that never rusts? Finding the recipes for such remarkable materials – called amorphous metals – should be easier using a new computational approach developed by Carnegie Mellon University physicist Michael Widom.

Described in an upcoming issue of Phys. Rev. B (September 1, 2004), this method already has been used to virtually generate recipes for more than 1,700 structures, many of which have never b

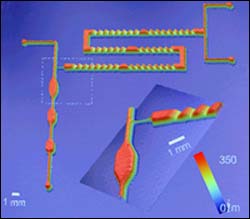

A new type of microfluidic device that can help industry to optimize paints, coatings for microelectronics and specialty polymers has been developed by National Institute of Standards and Technology (NIST) researchers. The device is made of a chemically durable plastic that is resistant to many common organic solvents. It was fabricated with a rapid prototyping method also developed at the agency.

Described in the Aug. 18 issue of the Journal of the American Chemical Society,* such

NASA decides to send astronauts to Mars and farther out, one of the biggest technological hurdles it will face will be making sure they don’t get thirsty.

A $49,000 toilet at Purdue University may provide part of the answer. When NASA engineers first considered manned missions to Mars to follow the moon landings, they imagined that the astronauts would simply pack lots of water and food.

“We could go to Mars with Apollo technologies,” said Dr. Daniel J. Barta, deputy manag

Time is fast running out for the semiconductor industry as transistors become ever smaller and their insulating layers of silicon dioxide, already only atoms in thickness, reach maximum shrinkage. In addition, the thinner the silicon layer becomes, the greater the amount of chemical dopants that must be used to maintain electrical contact. And the limit here also is close to being reached.

But a Cornell University researcher has caused an information industry buzz with the discover

A new generation of high surface-area porous materials for removing atrazine from water supplies has been developed by researchers at the University of Illinois at Urbana-Champaign. The low-cost and wear-resistant fibers also can remove the hazardous contaminants chloroform and trichloroethylene, both byproducts of the commonly used chlorine disinfection process.

“We’ve shown that we can remove all these impurities to well below the maximum contaminant levels established by the Env