This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

The findings, based on a single electrochemical process, could help cut emissions from the hardest-to-decarbonize industries, such as steel and cement. In the race to draw down greenhouse gas emissions…

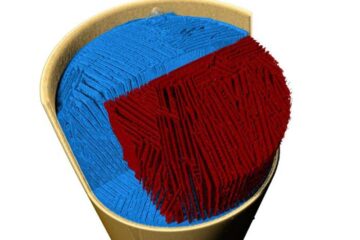

Freeze casting processes can be used to produce highly porous and hierarchically structured materials that have a large surface area. They are suitable for a wide variety of applications, as…

Hydrogen from electrolysis with renewable energies is considered a key element of the energy transition. By means of catalysts, water is split into its components hydrogen and oxygen. The electrochemical…

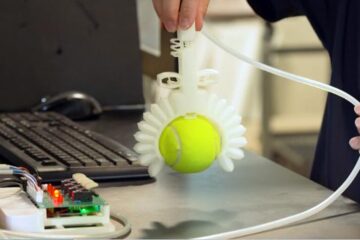

The device is printed all in one go and can pick and release objects. This soft robotic gripper is not only 3D printed in one print, it also doesn’t need…

… dry manufacturing process. The lithium-ion batteries used to power electric vehicles are key to a clean energy economy. But their electrodes are usually made using a wet slurry with…

LZH researches laser processes for formable hybrid components. Using expensive materials on high-performance components only where they are needed: This is the vision of the Collaborative Research Centre SFB 1153…