This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Research aids drug design; sheds light on plague and other diseases

A new technique for engineering protein crystals is helping scientists figure out the three-dimensional structures of some important biological molecules, including a key plague protein whose structure has eluded researchers until now. The technique, developed with support from the National Institute of General Medical Sciences (NIGMS) of the National Institutes of Health (NIH), promises to help pharmaceutical compani

Engineers from Duke University have described progress building so-called “smart nanostructures,” including billionths-of-a-meter-scale “nanobrushes” that can selectively and reversibly sprout from surfaces in response to changes in temperature or solvent chemistry.

In talks delivered during the March 28-April 1 at the American Chemical Society annual meeting in Anaheim, researchers from Duke’s Pratt School of Engineering also told how they are using an atomic force microscope to creat

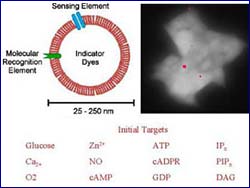

For two decades, chemists have been making great strides in analyzing the biological functions that drive living cells. But many biological substances still remain undetectable.

That will soon change, thanks to a biological sensor being developed by University of Arizona chemists. Their new sensor platform has many capabilities that current ones lack.

Most intracellular sensors are made from hard plastics (polymers). The plastic is formed into solid, nanometer-sized, BB-like beads,

Tiny machines built as part of silicon chips are all around us, and their need for lubrication is the same as large machines such as automobile engines, but conventional lubricants, like oils, are too heavy for these micro electromechanical systems (MEMS), so Penn State researchers are looking to gases to provide thin films of slippery coating.

MEMS today are mostly found in automobile air bags as the sensor that marks sudden deceleration and triggers airbag use. They can also take the for

Australian researchers who have worked quietly over several years in a long ignored area of metallurgy have been rewarded with a startling discovery, which is set to reshape the way metals are manufactured around the world.

CSIRO’s (Commonwealth Scientific & Industrial Research Organisation) Advanced Thixotropic Metallurgy (ATM) casting technology is now in the final proving-out stage and the results herald a new age of quality high-pressure die-casting (HPDC).

ATM is particul

Creating a tool small enough to measure friction on a microelectromechanical systems (MEMS) device is not an easy task. The tool has to be about the width of a human hair.

Yet, researchers at the at the National Nuclear Security Administration’s Sandia National Laboratories have developed a new “inchworm” actuator instrument that provides detailed information about friction at the microscale.

The main objective of the project was to study the validity of Amonton’s Law at