This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Self-cleaning hydrogen sensors may soon join the ranks of self-cleaning ovens, self-cleaning windows and self-cleaning public toilets, according to Penn State researchers.

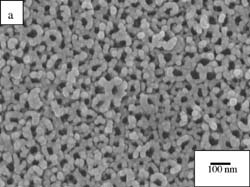

“The photocatalytic properties of titania nanotubes are so large — a factor of 100 times greater than any other form of titania — that sensor contaminants are efficiently removed with exposure to ultraviolet light, so that the sensors effectively recover or retain their original hydrogen sensitivity in real world applic

Carbon dioxide, an environmentally friendly solvent for dyeing and dry cleaning, may become a valuable new tool for making medical implants, according to a study at Ohio State University.

Engineers here used compressed carbon dioxide (CO2) to push chemicals into a plastic that is often used as a bone replacement. With further development, the technology could be used in a wide range of plastics that release medicines — from antibiotics to anti-tumor agents -– into the body.

The hig

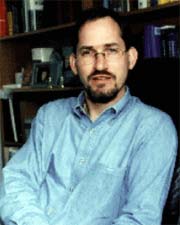

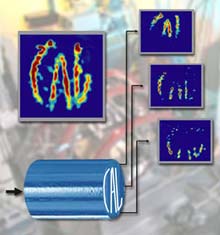

Alexander Pines and his colleagues have discovered a remarkable new way to improve the versatility and sensitivity of magnetic resonance imaging (MRI) and the technology upon which it is based, nuclear magnetic resonance (NMR).

Pines, a pioneering NMR researcher, is Faculty Senior Scientist in the Materials Sciences Division at Lawrence Berkeley National Laboratory and Glenn T. Seaborg Professor of Chemistry at the University of California at Berkeley. The latest details of the new techniqu

Member of the Department of Electrical and Electronic Engineering at the Public University of Navarre, Jesús Mª Corres Sanz, has suggested a new method which enables, amongst other applications, response enhancement to perturbations in electrical machines such as those experienced by an electric vehicle. These techniques, moreover, can be applied to any type of industrial robot.

In this thesis the design of velocity observers and perturbation par is studied for their application to mechatro

Every manufacturing process, from casting and forging, to machining and finishing, induces residual stresses in components. For critical components, such as aircraft wings and turbine blades, these stresses affect the durability and lifetime of the structures and assemblies. Current methods are either destructive (e.g. hole drilling), limited to the surface (laboratory X-ray), or rely on large facilities (synchrotron and neutron sources). The new method uses a laboratory source of high energy polychr

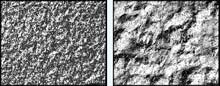

Using rigorous statistical analysis, National Institute of Standards and Technology (NIST) researchers identified a potential source of error in the surface roughness data used in the automotive industry to predict how friction affects production of metal parts during forming.

With this improved analysis, automakers should be able to more easily incorporate lighter weight materials in their products and improve fuel efficiency.

The NIST scientists presented their findings at the Soc