This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

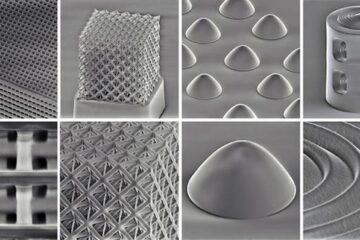

Process developed at KIT works at relatively low temperatures and reaches highest resolution for use in optics and semiconductors – publication in Science. Printing of micro- and nanometer-scaled quartz glass…

A new method for cleaning conveyor belts in food production can replace the widely used disinfection chemicals: plasma-treated water is effective against microbial contamination at a shorter exposure time and…

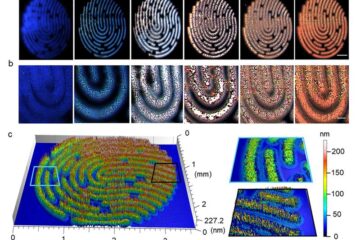

– Sweet code with laser printing. A team of researchers at the Max Planck Institute of Colloids and Interfaces (MPICI) has developed a method that could make it more difficult…

Ceramics recycling – energy-efficient and low in emissions… Silicon carbide is a popular industrial material for many applications. The extremely hard, heat-resistant material is used for refractory components and semiconductors,…

… in the Form of a Pill Finds Weak Spots in Machines and People. Imagine a scenario where you simply just throw in a pill to identify an error—this is…

Rice U. engineers improve prelithiation, uncover lithium-trapping mechanism. Silicon anode batteries have the potential to revolutionize energy storage capabilities, which is key to meeting climate goals and unlocking the full potential…