This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Researchers at Purdue University have developed a miniature device sensitive enough to detect a single virus particle, an advancement that could have many applications, including environmental-health monitoring and homeland security.

The device is a tiny “cantilever,” a diving board-like beam of silicon that naturally vibrates at a specific frequency. When a virus particle weighing about one-trillionth as much as a grain of rice lands on the cantilever, it vibrates at a different frequency,

Cutting high-thickness metal sheets is a basic manufacturing process common to a wide range of industrial sectors, from heavy carpentry to ship-building. Laser-cutting technology ought, in theory, to have significant advantages over traditional cutting processes, among them high cutting speed, no tool wear and a reduction in the transfer of energy to the piece of metal being cut. Yet despite the fact that commercial laser-cutting systems have been on the market for a decade, their use has not become

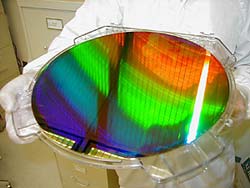

An MIT device that makes the world’s most precise rulers—with “ticks” only a few hundred billionths of a meter apart—could impact fields from the manufacture of computer chips to space physics.

The Nanoruler is 10 to 1,000 times faster and more precise than other methods for patterning parallel lines and spaces (known collectively as gratings) across large surfaces more than 12 inches in diameter. Such large surfaces are key to a number of applications involving gratings, such as larger waf

In a major advance for cryogenics, researchers at the National Institute of Standards and Technology (NIST) have developed a compact, solid-state refrigerator capable of reaching temperatures as low as 100 milliKelvin. The refrigerator works by removing hot electrons in a manner similar to an evaporative air-conditioner or “swamp cooler.”

When combined with an X-ray sensor, also being developed at NIST, the instrument will be useful in semiconductor manufacturing for identifying trace conta

EUREKA project E! 2339 EUROENVIRON GRINDING project has developed an alternative, flexible and environmentally friendly manufacturing technology for the production of gears that can reduce production times from months to a matter of days.

It can be used for all kinds of gears and joints made from treated alloyed steel, heat-resistant nickel or titanium alloys, such as those used in turbine and jet engine blades.

The current production process for industrial gears is expensive in terms of

Scottish company IceRobotics has taken a further step towards bringing its innovative robotic milking technology to market thanks to a second round investment package of £430,000. This includes £75,000 from NESTA (the National Endowment for Science, Technology & the Arts), the organisation that invests in UK creativity and innovation.

IceRobotics has developed a sophisticated vision-based sensor that can precisely target and track a cow’s teats, capturing the 3D coordinate data required to