Research from Braunschweig enables innovative pharmaceutical products

Use of additive manufacturing for the production of individualized pharmaceutical products.

Krees Nagel / Fraunhofer IST

Braunschweig continues to expand its strengths in the manufacture of individualized pharmaceutical products. For this purpose, the Fraunhofer Institute for Surface Engineering and Thin Films IST and the Center of Pharmaceutical Engineering (PVZ) of the Technische Universität Braunschweig are cooperating for the first time.

The Fraunhofer-Gesellschaft is providing 0.5 million euros to support the establishment of a translational laboratory for “Individualized Pharmaceutical Production” in Braunschweig as part of the new Lower Saxony High-Performance Center “Medical and Pharmaceutical Engineering”. A mutually usable infrastructure for the individualized production of pharmaceuticals is being created with the aim of jointly bringing research results and innovations into application even more quickly as well as supporting partners as innovation pilots.

Process-engineering and production technology from Braunschweig

Falko Oldenburg / Fraunhofer IST

Individualized pharmaceutical products are an important building block in patient-centered medicine. One goal of the research is to design tablets or capsules in such a way that they can be flexibly produced in small quantities, for example individually for a patient or a small group of patients. This imposes high demands on manufacturing. Process-engineering and production technology from Braunschweig is thereby set to play an important role in the future and is to be combined with the expertise from the pharmaceutical industry. Lower Saxony’s Minister for Science and Culture Björn Thümler welcomes the project: “The High-Performance Center ‘Medical and Pharmaceutical Engineering’ proves how strongly the life sciences are positioned in the Hannover/Braunschweig region. I am convinced that the cooperation between scientists from the Fraunhofer-Gesellschaft and the TU Braunschweig has the potential to produce new and individual pharmaceuticals.”

Improvements in manufacturing

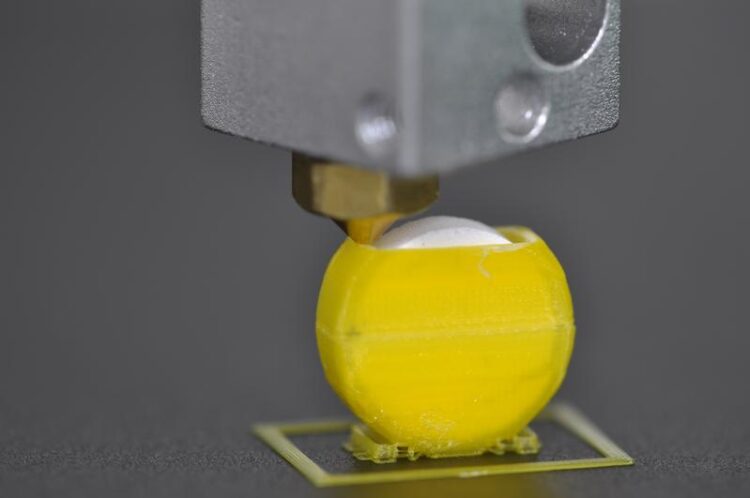

Thanks to the innovations from Braunschweig, novel medication forms are becoming possible. The scientists can, for example, control properties such as adhesion to machine surfaces, which means that the use of release agents in medicine production can be dispensed with, thereby improving the properties of the product. In addition, modification of the surface with a “cold” plasma can improve the flowability of powders and create barrier layers. This in turn also leads to new possibilities – for example, the combination of several active ingredients in one tablet which would otherwise not be compatible with one another. In collaboration with the PVZ, the Fraunhofer IST will also carry out research into new processes such as 3D printing in combination with innovative plasma systems and new surface coatings. These are to become part of a new modular process chain for the production of such individualized medication forms. The Fraunhofer and TU Braunschweig scientists assume that this research will also result in improvements and innovation impulses for mass production.

New translational laboratory intensifies regional cooperation

With the new translational laboratory, which is to commence operation in 2021 and be continuously expanded, the TU Braunschweig and the Fraunhofer-Gesellschaft are further expanding their cooperation at the location. Together with partners from industry and the civil society, new production technologies are to be transferred into application. This will facilitate the entry of interested companies into the partnership-based technology and process development in this future market. Furthermore, the transfer of knowledge into industrial practice is to be supported through training concepts. Such a translational laboratory for the individualized production of pharmaceutical products does not yet exist in Germany.

“This is an important step in the systematic expansion of our competence in the field of pharmaceutical production and the intensification of regional cooperation with the PVZ,” said Prof. Dr. Michael Thomas, Head of Department at the Fraunhofer IST and member of the PVZ. In his department, novel plasma systems operating at atmospheric pressure and functional surfaces are developed and integrated into processes. “These plasma systems can be miniaturized very successfully and incorporated into process chains,” explained Dr. Kristina Lachmann, Group Manager of Surface Chemistry and Atmospheric Pressure Plasma Processes at the Fraunhofer IST. “As a result, during the production process it is possible to control in-situ functions such as adhesion or to generate barrier layers, thereby achieving individualized manufacturing,” explained Dr. Lachmann. “We already have the first industrial partners on board who want to build with us the basis of the modular platform for generative manufacturing of pharmaceuticals and to drive forward the development in the long term,” explained Prof. Dr. Michael Thomas.

At the PVZ, the staff are also excited about the fact that this platform is now being established. “We have been pursuing the approach of individualized medicine production for quite some time,” explains Prof. Dr.-Ing. Arno Kwade, Spokesman of the Board of the PVZ. “We are delighted that the Fraunhofer IST, as a regional partner, is driving this topic forward with the institutes of the PVZ and is hereby contributing its expertise in process-engineering and production technology as well as in functional surfaces as a new and important competence in order to successfully expedite this crucial branch of research at the PVZ.” For the future, the partners are planning increased research into the digitization and monitoring of processes, as well as extensions to the development of new types of packaging concepts – thereby pursuing the aim of keeping processes transparent and comprehensible. As a result, it should be possible to reliably verify and document the quality of every single individual medication form and to track it all the way through to the point of ingestion.

Background

The Fraunhofer Institute for Toxicology and Experimental Medicine ITEM in Hanover, the Fraunhofer Research Institution for Individualized and Cell-Based Medical Engineering IMTE in Lübeck, and the Fraunhofer Institute for Surface Engineering and Thin Films IST in Braunschweig have joined forces within the Fraunhofer High-Performance Center “Medical and Pharmaceutical Engineering”, which is funded by the state of Lower Saxony and the Fraunhofer-Gesellschaft. The focus of the High-Performance Center with location-specific translational laboratories will be placed on the individualized production of pharmaceuticals (Braunschweig location), the development of intelligent respiratory systems, and additively manufactured implants. In addition to various companies, location-specific research partners include the Medizinische Hochschule Hannover (MHH), the Leibniz University Hannover (LUH), the Universität zu Lübeck, the University Medical Center Schleswig-Holstein (UKSH), and the Technische Universität Braunschweig with its Center of Pharmaceutical Engineering (PVZ). The goal of the High-Performance Center is to close the gap between university and non-university research and industry and to accelerate the innovation process from the idea through to the market. For this purpose, not only the necessary infrastructure is being provided; important players from business and science are also being networked.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…