Sandblasting with Light

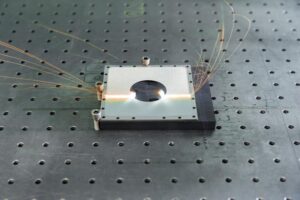

Sandblasting at the speed of light: Fraunhofer IWS uses high-energy light instead of sand grains to clean and roughen – for example the surface of brake discs.

© René Jungnickel/Fraunhofer IWS

Fraunhofer IWS developed a laser technology to clean and structure surfaces particularly quickly while protecting the environment.

Sandblasting – that was yesterday. Laser beams can clean and structure surfaces more precisely, cost-effectively and in environmental friendlier ways than conventional systems. The Fraunhofer Institute for Material and Beam Technology IWS in Dresden has developed the technology “LIGHTblast” for this purpose which is now being transferred to the semiconductor manufacturing, automotive supply and other industries.

The Fraunhofer IWS researchers see considerable ecological and economic potential: “This is like sandblasting at the speed of light,” explains Dr. Patrick Herwig, who heads the Laser Cutting Group at the institute. “We are thus enabling industry to process equipment and components faster, more environmentally friendly and cleaner than before. Considering the entire production chain, our process is less expensive than classic sandblasting when used in series production. We are certain that laser technology will pay off for companies.” Fraunhofer IWS is currently preparing initial application examples with various end users. Laser systems could soon replace sandblasting systems step by step there.

High Energy Light Replaces Sand Grains

© René Jungnickel/Fraunhofer IWS

The market potential is considerable. Indeed, the number of industries using classic sandblasting systems is increasing. Not only do they remove any contamination from a wide variety of components, but they also roughen them in a defined manner prior to coating, thus optimizing the result of the coating process. Occasionally, sand particles are embedded into the treated surface, which remain as a defect even after intense cleaning. In conventional processes, a jet of compressed air accelerates sand at high speed onto the target surface. The sharp-edged sand particles tear away parts of the surface, causing the sharp edges to wear away and mix with the resulting dust. With each use, the blasting medium contaminates more and steadily round grinds. The process result continuously deteriorates. Ultimately, the mixture must be disposed of as special waste, which pollutes the environment and causes additional costs.

Fraunhofer IWS uses high-energy light instead of sand grains to clean and roughen. For this purpose, researchers developed the laser-based process “LIGHTblast” that realizes cleaning and structuring tasks significantly faster than conventional processes and should result in lower operating costs in series production. The process can also be automated more easily with positive effects on quality, process control and occupational safety. In addition, the system works much more precisely than a sandblasting system, as a laser beam with a diameter of less than 50 micrometers (i.e. thousandths of a millimeter) replaces a particle stream several centimeters wide. “In a sense, we are working with a scalpel instead of a club,” Patrick Herwig explains metaphorically. How rough the surface ends up can also be very finely adjusted with the new method.

Environmental relief

Apart from the cost and quality benefits, the ecological balance of their manufacturing processes is becoming increasingly important for many industrial users. Thus, many pre- and post-processing steps are eliminated: The light-based processing does not require any chemicals for cleaning. The laser blasting system precisely processes only the desired surfaces, consuming neither sand nor material for masking and thus saving hazardous waste and adhesive tape waste. The laser beam vaporizes parts of the surface, the expanding vapor carries away solid components and also achieves a defined roughness.

Several industrial companies have already recognized these and other advantages of light sandblasting. They now want to gradually transfer the technology into manufacturing practice together with the Fraunhofer researchers. For example, Fraunhofer IWS and a partner are further developing the process to structure hard material coatings by means of laser technology and to decisively improve the finishing process with regard to costs and environmental compatibility. “Every brake disc is different,” says René Bischoff, Chief Technology Officer at C4 Laser Technology from Freital near Dresden. “Factors such as the chemical material composition, cooling rates, the condition of the machining tools or the graphite structure near the surface are just a few parameters exerting a considerable influence on the coating process of gray cast iron surfaces. Together with Fraunhofer IWS we have found a way to standardize the friction band surface condition of the brake disc blank before coating. Thus, we succeeded in making the normalization process fully automatable as well as cost-efficient and in increasing the process capability.” As part of the production chain, the process thus contributes to an affordable brake disc whose significantly extended service life will ensure that less particulate matter will be produced in road traffic in the future. Among other things, the Dresden institute is contributing its expertise in the design of laser-based manufacturing processes and in software development for process control.

In general, the new method can be applied wherever components need to be cleaned, pre-structured or roughened for subsequent coating. Further development steps are planned for this purpose.

Infobox

LIGHTblast at a Glance

- 100 times faster than known microstructuring with processing speeds of up to 10 cm²/s

- Simple substitution through use of identical media connections as for sandblasting system

- Avoidance of blasting media and masking prevents component contamination, waste and operating costs

- Definition of surfaces to be processed via CAD at the click of a mouse

- Roughness precisely selectable from Rz= 2 µm to 200 µm

About C4 Laser Technology GmbH

C4 Laser Technology is a technology developer and licensor of surface coatings for brake discs used in the automotive industry and for applications in industrial plant engineering. The company is engaged in the development and production of new coating materials – long-term corrosion protection solutions, for the first time for the entire fan duct structure, as well as wear-reducing coating systems on friction bands.

Wissenschaftliche Ansprechpartner:

Dr.-Ing. Patrick Herwig

Group Manager Laser Cutting

Fraunhofer Institute for Material and Beam Technology IWS Dresden

Winterbergstraße 28, DE-01277 Dresden

Phone +49 351 83391-3199

patrick.herwig@iws.fraunhofer.de

www.iws.fraunhofer.de

Originalpublikation:

https://www.iws.fraunhofer.de/en/newsandmedia/press_releases/2022/press-release_…

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…