Structure formation during freeze casting filmed in 3D and real time

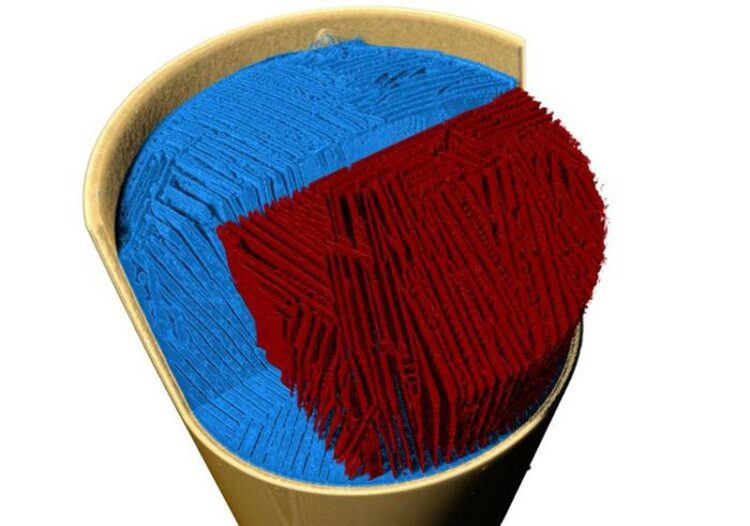

A 3D-rendered tomogram shows a cross-section through the solidified sample in which two phases have separated: the pure ice crystal phase in blue and the sugar phase in red. The lamellar structure formed by the snowflake-like ice crystals is clearly visible.

Credit: HZB/PSI

Freeze casting processes can be used to produce highly porous and hierarchically structured materials that have a large surface area. They are suitable for a wide variety of applications, as electrodes for batteries, catalyst materials or in biomedicine. Now a team led by Prof. Ulrike G. K. Wegst, Northeastern University, Boston, MA, USA and Dr. Francisco García Moreno from the Helmholtz-Zentrum Berlin have now used the newly developed X-ray tomoscopy technique at the Swiss Light Source of the Paul Scherrer Institute to observe in real time and at high resolution how the process of structure formation takes place during freezing. A sugar solution served as the model system.

Freeze-casting requires several steps: First, substances are dissolved or suspended in a solvent and then frozen in a mold with a cooling rate applied to the bottom (directional solidification). After freezing, the solid solvent phase is removed by sublimation. What remains are the previously dissolved solute molecules and suspended particles, which form the cell walls of the resulting complex, highly porous architecture. Freeze-cast materials can be used for many applications: for instance, due to their enormous internal surface areas as battery electrodes or catalysts or because of their aligned porosity in biomedical applications for example as scaffolds for peripheral nerve repair. However, exactly how the ice templates the complex architecture during freezing, and how the desired honeycomb-like aligned porosity and the cell walls with their various surface features are formed, has remained little understood until now.

Dr Francisco García Moreno and his team at Helmholtz-Zentrum Berlin have developed a method to observe these highly dynamic processes in detail. “Using X-ray tomoscopy, we can image the formation of structures in situ with high spatial and temporal resolution and even observe transient phenomena and transitional structures,” explains the physicist. Using an ultrafast turntable, intense X-rays, an extremely fast detector and software for rapid analysis of the X-ray data, the HZB team, together with colleagues at the Swiss Light Source of the Paul Scherrer Institute, studied freeze casting on a model system and demonstrated the high performance of the method. “For this study, we developed a new measuring cell with sensors to precisely record the temperature gradient,” says Dr Paul Kamm (HZB), lead author of the study. A 3D tomogram with a spatial resolution of 6 µm per second was generated. The entire freezing process was documented over 270 seconds.

Prof. Ulrike G. K. Wegst from Northeastern University, USA, had suggested an aqueous sugar solution as a polymeric model system, since this system can be simulated computationally, and because aqueous solutions still dominate the freeze casting process. “We are now able to experimentally observe for the first time the dynamics of directional ice crystal grow from the liquid phase,” says Wegst. “In doing so, the images document how instabilities form during crystal growth, how these shape the sugar phase and how characteristic, organic-looking structures are formed on the cell walls that are reminiscent of jellyfish and tentacles.” It is also interesting to note that some of these structures may disappear again.

Journal: Advanced Functional Materials

DOI: 10.1002/adfm.202304738

Method of Research: Experimental study

Subject of Research: Not applicable

Article Title: X‐Ray Tomoscopy Reveals the Dynamics of Ice Templating

Article Publication Date: 18-Aug-2023

COI Statement: none

Media Contact

Antonia Roetger

Helmholtz-Zentrum Berlin für Materialien und Energie

antonia.roetger@helmholtz-berlin.de

Office: 0049-308-062-43733

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…