A Finger on the Pulse of Innovation – Worldwide

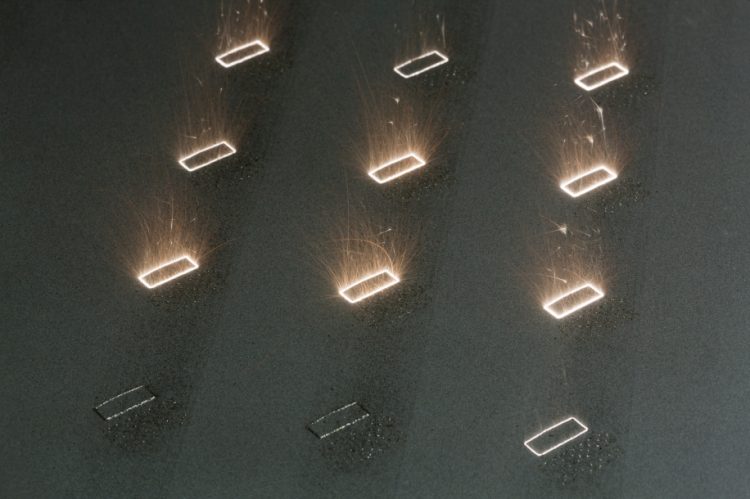

A glimpse into a laser chamber, where a 3D object is being created from metal particles.

The 21st century is a highly dynamic period. With the march of globalization has come a steady increase in worldwide competition. The balance of power in the world of research and development (R&D) is also drifting away from the erstwhile industrial nations and toward the emerging economies.

This relocation offers a host of opportunities for companies to shift and consolidate their positions in a rapidly changing global market.

For a company as global as Siemens, it is crucial to have a finger on the pulse of the most important markets. This is true not only of sales but also of research. “People set new trends. And to work with these trendsetters, you need to be there on the ground, where these people live,” explains Dr. Norbert Gaus, Director of the Research and Technology Center at Siemens Corporate Technology (CT). Siemens currently has some 30,000 employees working in R&D at over 170 locations worldwide.

In particular, Corporate Technology (CT) – Siemens’ central research department – sets the course for future innovations and even for future areas of business. All in all, CT operates 21 R&D centers around the world, with a total of 7,800 researchers, developers, and other experts. Locations in the U.S., Germany, India, and China are responsible for key priorities.

Additive Manufacturing – A Global Research Field with a Big Future

At Siemens’ Princeton, New Jersey R&D campus, which is based just outside the idyllic university town of the same name, around 200 researchers cover a broad range of subjects. Key topics are digital technology and industrial automation. These cover important aspects of additive manufacturing, also known as 3D printing.

It’s for this reason that the rooms occupied by the research group in the Additive Manufacturing Engineering Technology Field look a little like a huge toy box, strewn with lots of colorful objects produced by a simple 3D printer. Whether toy-like figures made of plastic or miniature models of turbine blades, all of the objects are responses to a basic question:

How can objects be designed on a computer in such a way that they can be optimally produced by additive manufacturing? With this technology, established design rules and familiar material properties no longer apply. Specifically, specialists in Princeton are working on design methods that will then find their way into Siemens products such as PLM software for computer-aided design and engineering.

These programs make it possible to plan and implement production processes partly along conventional lines and partly on the basis of additive manufacturing.

Additive manufacturing is also a topic of interest for CT researchers in Berlin. Unlike Princeton, however, the focus here is less on the question of the printed object’s design and much more on the choice of materials, their properties, and the development of manufacturing techniques. Another difference is that here the trial models tend to be made of metal rather than the plastic frequently used in Princeton.

Depending on the actual process used, this metal might first be pulverized and then fused layer by layer – i.e. added, hence the name of this technology – by means of a process known as selective laser melting. The goal of this research is to make it possible in the near future to simply “print out” spare parts for, say, a gas turbine and fit them directly, thereby eliminating weeks of waiting for delivery.

Sensors: A Data Source for the Web of Systems

Siemens Corporate Technology’s largest location is on the outskirts of Munich. Here, where some 850 scientists work, facilities include the labs of the Sensor Technology Field, which focuses on new sensor systems with a vast range of applications. Sensors are a source of data in the industrial environment and are therefore indispensable for the digital evolution of industry.

This is true of all the businesses at Siemens – ranging from facility automation to the monitoring and control of complex facilities and infrastructures, as well as mobility solutions. Sensor systems provide the basis for what is called a web of systems, in which devices and systems are networked with one another and are endowed with a degree of intelligence by means of software applications.

At the same time, they are also vital for data analytics applications, which learn to control facilities more and more efficiently on the basis of a steady feed of data from sensors. Here too, CT experts are working in close collaboration with colleagues from the business units and other CT locations worldwide.

“At Siemens, research should lead to innovative products; that’s the point where research turns into innovation,” Gaus explains. “Our research in the areas of additive manufacturing and sensor systems provides two good examples of how research groups from our CT locations working in different technology fields work closely with business units worldwide.”

This is what ensures that development work leads to successful innovations. And this is also why Siemens has research groups not only in its major countries for product development, such as Germany, China, India, and the U.S., but also in locations where key developments can be advanced together with the customer. For example, in Vienna, Austria, which is home to Aspern, an entirely new “smart city,” innovative infrastructure technologies are now undergoing trials in close consultation with the client – and, thanks to the local CT presence, improved on the spot in cooperation with company divisions.

CT in India and China: Software that Meets the Needs of Emerging Markets

Software is one of the main focus areas for CT employees in India – or, more precisely, for CT’s Development Services software house. Over 3,000 employees develop software in Bangalore for 30 areas of business – not only for the Indian market but also for markets worldwide ((link to India article here)). Meanwhile, the 400 employees at CT’s locations in Beijing, Shanghai, and Nanjing are working on a range of technologies that are used in Siemens products. Here, once again, the strategy is to team up with the business units and to work as closely as possible with customers so as to act as an interface between customer requirements, on the one hand, and what is technically and economically feasible, on the other. “China is a huge market with very precise product requirements,” Gaus explains.

Here, products must be easy to use, highly robust, and priced at a level that corresponds to the general price level in China and similar markets. CT employees in China are involved in all of the most important research projects so as to ensure that these requirements are observed. Results confirm the strength of this strategy. Knowledge gathered in the Chinese market has already been used in solutions for other markets such as India and Brazil. These solutions include CT scanners developed by Siemens researchers in China, which are now being sold in those countries. In addition, Siemens plans to open its very own Digital Innovation Center in China in 2016. This R&D facility will concentrate on cross-divisional projects focusing on new digital solutions for both the Chinese market and markets further afield where the “Chinese way to new technology” opens up new options.

Whether in the U.S., Germany, India, or China, the R&D activities described above represent only a few of the many examples where innovation at Siemens is a truly global affair and is being driven by international research teams. In this way the company can profit from the concentrated know-how of its employees on the ground. What’s more, thanks to its international configuration, Siemens also gains firsthand knowledge about different market requirements around the world. And for a company with the global presence of Siemens, that kind of knowledge is invaluable.

Katrin Nikolaus / Sebastian Webel

Redaktion

Sebastian Webel

Dr. Norbert Aschenbrenner

Dr. Johannes von Karczewski

Kontakt für Journalisten

Florian Martini

Tel.: +49 (89) 636-33446

Media Contact

All latest news from the category: Science Education

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…