The dream of a cleaner, greener transportation future burns brightly in the promise of hydrogen-fueled, internal combustion engine automobiles. Modern-day…

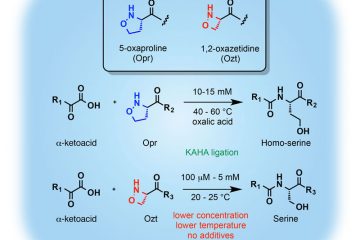

The development of new methods for the chemical synthesis of proteins is highly significant to access a range of proteins inaccessible by conventional…

A major challenge of construction within existing contexts is that renovated as well as newly built supporting structures have to comply with similar requirements regarding statics and outer appearance. E.g. component connections have to comply with standards in the fields of fire protection, corrosion protection and protection of historical monuments. Steel elements pasted into wood provide a solution for these rquirements.

GNSS enables the determination of positions by the help of a carrier phase with an accuracy down to some centimeters. The GNSS receivers typically determine the carrier phase by help of a phase locked loop continuously. However, up to now GNSS receivers are tracking the carrier phase of each satellite and each frequency separately. This is a big drawback since the strong spectral and spatial correlation between carrier phases is not being exploited which makes phase tracking error-prone. Furthermore, this leads to a number of phase jumps especially with low-cost GNSS receivers. The new patented invention comprises a vector phase tracking method, which processes the carrier phases of all visible satellites on all available frequencies simultaneously, thus using the spectral and spatial correlation of the measurement. It enables a continuous, smooth tracking of carrier phases, even when the signal strength (C/NO) of individual satellites breaks down by 20 dB. Therefore the method is very suitable for the use of low-cost GNSS receivers/antennas in environments with multiple faults and ionospheric scintillations.

Device for machining with rotatory ultrasound-vibrations: Reduced tool wear, very fine surface roughness and only little feathering of workpieces prove the advantages of hybrid manufacturing processes such as ultrasound machining. A newly developed device for machining combined with rotatory ultrasound oscillations enables a low-wear and thus more efficient processing of high performance materials such as hard metal, ceramic and fiber-reinforced plastics, compared to conventional methods.

Think of an object made of iron: An I-beam, a car frame, a nail. Now imagine that half of the iron in that object owes its existence to bacteria living two and…