Battery Production: Laser Light instead of Oven-Drying and Vacuum Technology

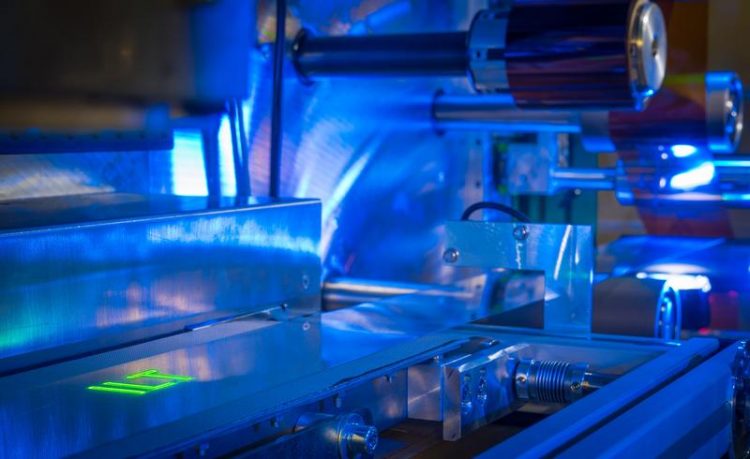

In the project ProSoLitBat, funded by BMBF, a roll-to-roll process chain has been generated for the continuous production of lithium solid electrolyte batteries. © Fraunhofer ILT, Aachen, Germany

In the truest sense, it’s all about watts at the Dresden-based Fraunhofer Institute for Ceramic Technologies and Systems IKTS and the Aachen-based Fraunhofer Institute for Laser Technology ILT. The joint project “DRYLAS – Laser-based Drying of Battery Electrode Slurries” focusses on the energy-efficient drying of electrode layers, so-called slurries, which are applied in a wet-chemical process to the current-conducting metal foils during battery production.

Until now, continuous furnaces have been used, which remove the solvent contained in the slurry during the drying process. Dr. Dominik Hawelka, a scientist at the Fraunhofer ILT, gets to the heart of the reasoning behind this research project: “In these furnaces, the energy deposition is not very efficient as compared to a laser treatment. That is why we have decided to use the very precisely controllable laser radiation as the drying tool for this application.”

Energy consumption halved

The two institutes have designed an in-line process and a fiber-laser based drying module which has already proven itself in initial tests in a so-called roll-to-roll plant of the Fraunhofer IKTS in Dresden. “The laser radiation is absorbed directly in the slurry and minimizes heat losses to the surroundings,” says the physicist. “Our drying process uses about half of the energy that the continuous furnace needs.”

The two institutes have also demonstrated that the fiber-laser dried electrodes can be used to build sound battery cells that work just as flawlessly as components treated conventionally in a continuous furnace.

Continuous production with a roll-to-roll process chain

The Fraunhofer ILT is also using its expertise in laser technology to put photonic process and plant engineering into practice: in particular, in the project ProSoLitBat, funded by the German Federal Ministry of Education and Research (BMBF) and coordinated by SCHMID Energy Systems GmbH from Dunningen.

This project focuses on the industrial, continuous production of lithium, solid-state batteries in thin film technology. The aim of the current project, which will run until 2017, is to make a so-called roll-to-roll process chain viable as an alternative to the vacuum method previously used. The discontinuous, or batch-type vacuum process is extremely complex and costly.

“In contrast, continuous production can produce significantly higher quantities at a lower cost, which will help the solid-state lithium batteries to find wider applications,” explains Dipl.-Ing. Christian Hördemann, a scientist at Fraunhofer ILT. “We have built a pilot plant that works with an inert gas atmosphere, and with it we can now pattern and decollate batteries with integrated ultrafast lasers.” The company SCHMID Energy Systems shall make the process from Aachen ready for series production.

Fraunhofer Battery Alliance at the BATTERY + STORAGE trade fair

You can obtain details on both projects at the booth of the Fraunhofer Battery Alliance (Hall C2 B 41) in the BATTERY + STORAGE exhibition area at the WORLD OF ENERGY SOLUTIONS in Stuttgart. This international trade fair and conference for the convergence of energy generation, storage systems and mobility solutions will take place from October 12 to 14, 2015.

Contact

Dipl.-Ing- Christian Hördemann

Thin Film Processing Group

Telephone +49 241 8906-8013

christian.hoerdemann@ilt.fraunhofer.de

Dr.-Ing. Dominik Hawelka

Micro and Nanostructuring Group

Telephone +49 241 8906-676

dominik.hawelka@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

http://www.ilt.fraunhofer.de

https://www.fraunhofer.de/en/institutes-research-establishments/groups-alliances…

Media Contact

All latest news from the category: Trade Fair News

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…