Hannover Messe: Inkjet process to cost-efficiently print flexible touchscreens

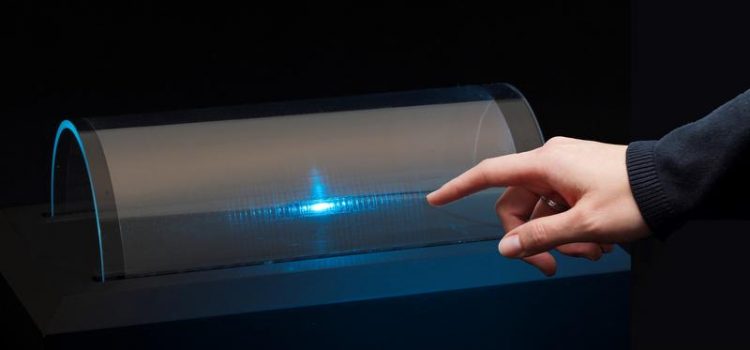

Flexible touchscreens with inkjetprinting. Source: INM; free within this press release

INM will be demonstrating flexible touch screens, which are produced by printing recently developed nanoparticle inks on thin plastic foils. These inks composed predominantly of transparent, conductive oxides (TCOs) are suitable for a one-step printing process.

The transparent lines and patterns are obtained by inkjet printing or alternatively by direct gravure printing, which are electrically conductive even after bending. Thus, a one-step-printing process for cost-efficient electrode patterns is enabled.

Conductive coatings with TCOs are usually applied by means of high vacuum techniques such as sputtering. For patterning of the TCO coatings additional cost-intensive process steps are necessary, for example photolithography and etching.

“We produce TCO nanoparticles with special surface properties,” explains Peter William de Oliveira, Head of the Optical Materials Program Division. “The TCO ink is then created by adding a solvent and a special binder to these TCO particles. The binder performs several tasks here: it not only makes the TCO nanoparticles adhere well on the substrate; but it also increases the flexibility of the TCO coating: in this way, the conductivity is maintained even when the films are bent. Using an adapted electrode pattern, flexible capacitive touch screen sensors with high sensitivity and resolution is printed in a simple process”.

After curing under UV light at low temperatures less than 130 degrees centigrade, the touch screen is completed.

Transparent, electronically conductive inks allow conductor tracks to be produced easily even on classic reel-to-reel processes. Initial trials at INM have been promising. The researchers all agree that in the future the use of structured rollers will allow structured, conductive surfaces to be printed with a high throughput at low cost.

Your expert at INM

Dr. Peter William de Oliveira

INM – Leibniz Institute for New Materials

Head Optical Materials

Head InnovationCenter INM

Phone: +49681-9300-148

OptiMat@leibniz-inm.de

INM – Leibniz Institute for New Materials, situated in Saarbrücken, is an internationally leading centre for materials research. INM conducts research and development to create new materials – for today, tomorrow and beyond. Research at INM is performed in three fields: Nanocomposite Technology, Interface Materials, and Bio Interfaces. INM is an institute of the Leibniz Association and has about 240 employees.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…