Launch of New Industry Working Group for Process Control in Laser Material Processing

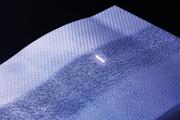

Image 1: Surface structuring with laser radiation. © Fraunhofer IPT, Aachen, Germany.

In the age of industry 4.0, laser technology is firmly established within manufacturing. A wide variety of laser techniques – from USP ablation and additive manufacturing to laser polishing – are now commonplace in large-scale production.

Cost structures, new materials and new processes are framing the demands placed on lasers and process engineering, of which process control is an essential element. Process control has developed steadily over the past few years in terms of performance and reliability, and is being used more and more by manufacturing companies.

More stringent demands placed on process monitoring

New sensors paired with innovative signal analysis now permit more accurate diagnosis of faults in laser-based processes. Today’s lasers offer equally high levels of performance and brilliance. This means that laser processes are becoming ever faster, which often leads manufacturers to exhaust process limits as they seek to maximize profitability.

Process windows are thus becoming narrower and narrower, which in turn raises the importance of process monitoring. The demands placed on the sensor technology in process control are thus correspondingly high: suitable measuring points need to be identified in the manufacturing process, the correct sensors need to be integrated and appropriate automated processes need to be found to ensure rapid detection of quality issues. Overall this represents a considerable challenge for users and manufacturers.

Accumulated expertise: the Industry Working Group for Process Control

At the process control seminar during AKL’16, it was apparent that there is great interest among users in new developments in process control. To meet users’ needs for support in this area, the Fraunhofer Institutes for Laser Technology ILT and for Production Technology IPT in Aachen announced the launch of the Industry Working Group for Process Control in Laser Material Processing.

The working group is aimed at users of laser techniques across a wide variety of sectors. Together with the research units, users in the working group can define and carry out pre-competitive projects such as feasibility studies or develop benchmarks, for instance. Members of the working group have access to the latest expert knowledge and trend analyses.

Particular emphasis is placed on encouraging an exchange of information, both among users themselves and with experts. Moreover, members have direct access to research and funding projects as well as training opportunities. The activities of the working group are funded by membership fees. To date, some ten companies have expressed interest and are in discussions with the organizers. Further members are very welcome!

With the inaugural meeting planned for autumn 2016, interested parties are now free to submit topics and questions for discussion.

Become a member of our working group! If you would like more details, get in touch with the contacts listed below.

Contact

Dipl.-Ing. Peter Abels

Group Manager Process Control and System Technology

Telephone +49 241 8906-428

peter.abels@ilt.fraunhofer.de

M.Sc. Ulrich Thombansen

Coordination of Industry Working Group for Process Control

Telephone +49 241 8906-320

ulrich.thombansen@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT, Aachen, Germany

Dipl.-Ing. Reik Krappig

Manager Business Unit Optics

Telephone +49 241 8904-327

reik.krappig@ipt.fraunhofer.de

M.Sc. Philippe Ackermann

Telephone +49 241 8904-540

philippe.ackermann@ipt.fraunhofer.de

Fraunhofer Institute for Production Technology IPT, Aachen, Germany

http://www.ilt.fraunhofer.de/

http://www.ipt.fraunhofer.de/

http://www.laserprocesscontrol.org

Media Contact

All latest news from the category: Trade Fair News

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…