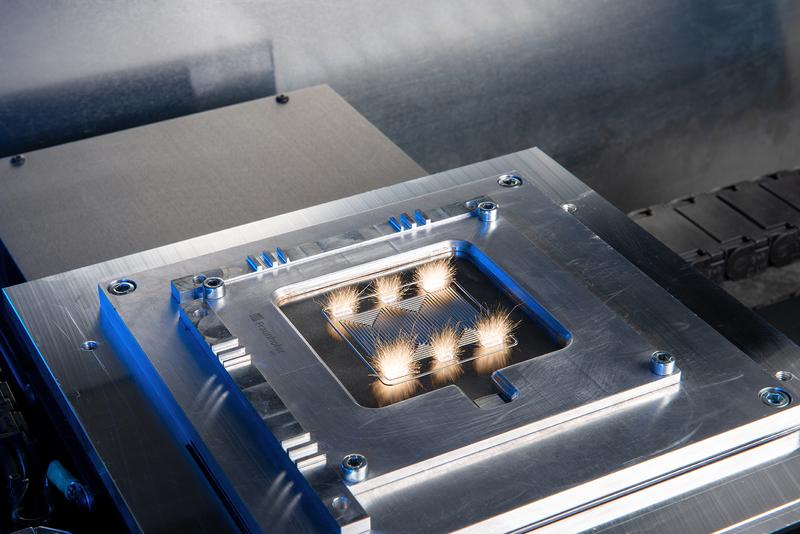

New benchmark for the industry: Fraunhofer ILT and Dreher Automation present laser blanking system at Euroblech 2024. The Fraunhofer Institute for Laser Technology ILT and Automatic-Systeme Dreher GmbH are presenting a groundbreaking innovation in the field of sheet metal processing at Euroblech 2024 from October 22 to 25 in Hanover, Germany: a demonstrator system for laser blanking that significantly increases process reliability and efficiency in production through the use of artificial intelligence. In modern production, especially in the automotive industry,…

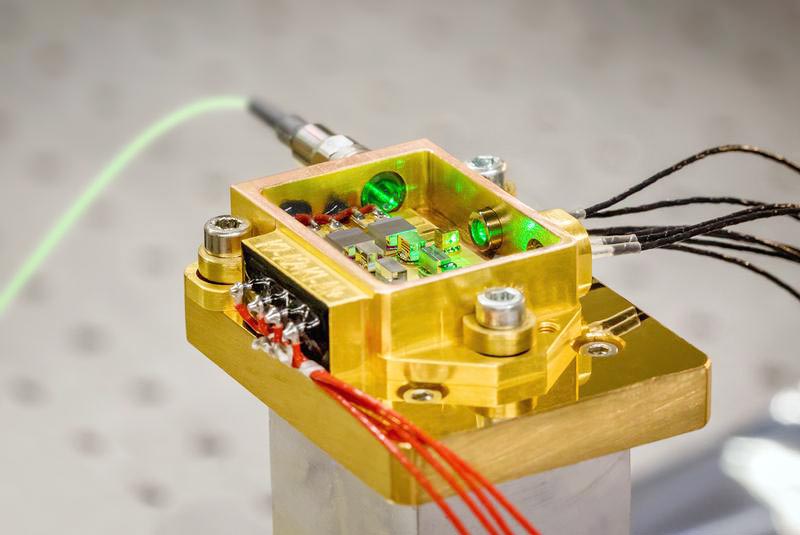

The Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) presents its advanced developments at the Photonics Days Berlin Brandenburg both at the conference and the accompanying exhibition. The Photonics Days will be held on October 5 and 6, 2022 in Berlin Adlershof and bring together experts from photonics, optics, microsystems technology, and quantum technology. Scientists from the Ferdinand-Braun-Institut are actively involved as chairs of the sessions “Berlin Laser Tech Symposium” and “Berlin Quantum Optics Symposium”. In a talk, they also present the progress…

To make the advantages of 5G for the process industry visible, the Fraunhofer Institute for Production Technology IPT from Aachen is installing and hosting a 5G mobile system for the first time at Achema, the leading trade fair for the process industry. The Aachen-based scientists are using a newly developed prototype to illustrate how the status of a pumping system can be monitored in real time. The prototype can be viewed at Achema in Frankfurt from August 22 to 26,…

From high-gloss brochures to new cars: paint layers that are also supposed to shine in front of customers must be smooth and even to reflect perfect quality. The Fraunhofer Institute for Production Technology IPT in Aachen, Germany, has developed an interferometric measurement method that can be used to reliably measure whether thin transparent layers of paint have been applied evenly: The possibilities offered by optical coherence tomography (OCT) for measuring such paint layers will be presented to the trade fair…

Until now, wastewater treatment plants have not been able to sufficiently filter out tiny microplastics in wastewater, but this could soon change: The first laser-drilled microplastic filter is being tested in a wastewater treatment plant. It contains sheets with extremely small holes just 10 micrometers in diameter. The technology to efficiently drill millions of such holes was developed at the Fraunhofer Institute for Laser Technology ILT, and now the institute’s engineers are scaling up ultrashortpulse (USP) laser technology in the…

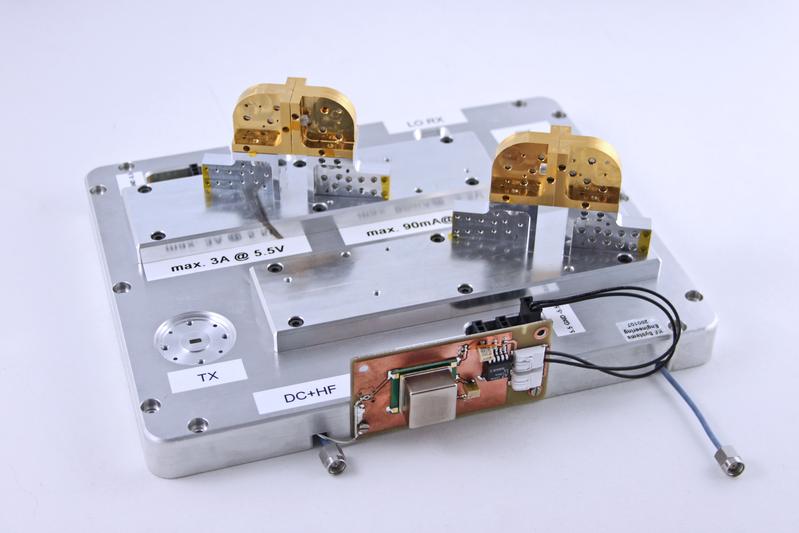

Fraunhofer FHR shows state-of-the-art radar technology at European Microwave Week in London. Future technology on the Thames: the Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR will present the wide range of its capabilities at the 24th European Microwave Week 2021 (EuMW), which will take place in London from April 2 to 7, 2022 after being postponed due to the pandemic. Industry and science will now come together again on site at Europe’s leading trade fair and conference…

Was there life on Mars? This is the question that the European Space Agency (ESA) is setting out to answer with its ExoMars mission. The mission, in which Russia is a participant, is scheduled to launch this fall, although recent political developments have raised questions as to whether this will be possible. Part of the mission is an analytical system that was designed to operate in space and was created as part of the research work conducted at the Fraunhofer…

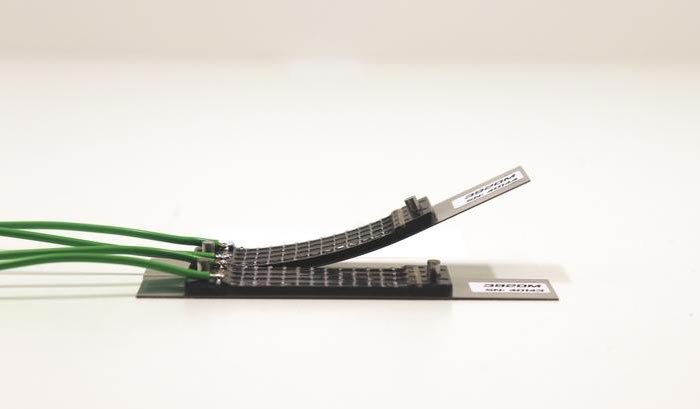

Technologies optimizing aerodynamics of planes and cars are traditionally only designed for one speed range. The start-up “CompActive”, a spin-off of the TU Kaiserslautern, has designed an intelligent material that automatically adapts to changing conditions thanks to shape memory alloy wires. The flexible actuators can also be used to open containers containing food without human contact. CompActive will present their materials at the digital Hannover Messe from 12 to 16 April at the Rhineland-Palatinate research and innovation stand. Eagles are…

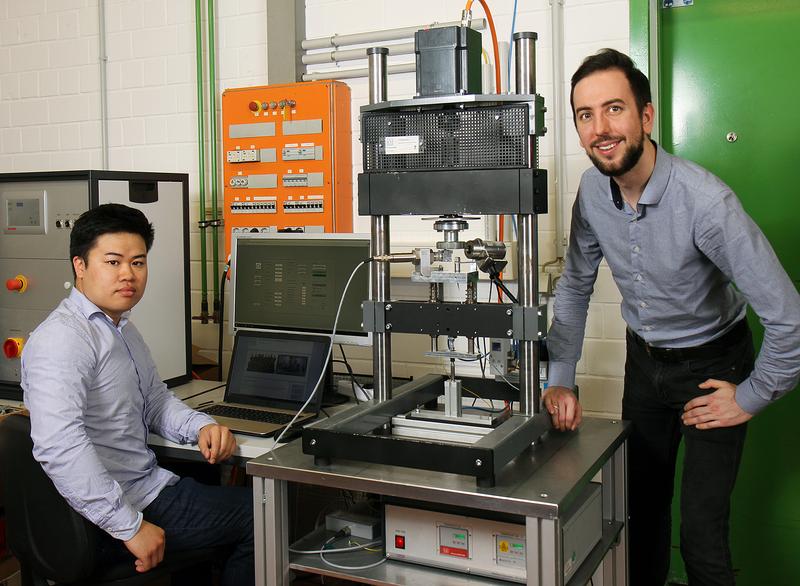

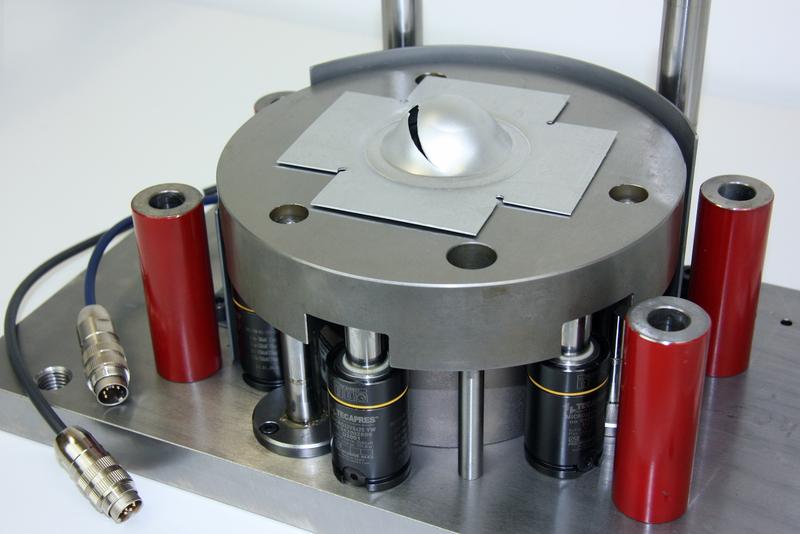

Whether in car tires or gears in production – friction and wear lead to losses. In Germany, this causes annual economic damage amounting to around five percent of the gross domestic product. It is therefore important to develop and test materials that minimize friction, such as plastic-metal combinations. Researchers from Kaiserslautern have developed a new system that automatically detects steady-state wear and analyzes data directly. They will present this technology at the digital Hannover Messe from 12 to 16 April…

Hannover Messe Digital Edition 2021: Autonomous, data-driven production optimization … As connectivity increases in production processes, so does their complexity. Data analysis expertise is required for predicting equipment outages in good time and detecting what causes losses in efficiency. MOEE, the tool that research teams from the Fraunhofer Institute for Manufacturing Engineering and Automation IPA are exhibiting at the Hannover Messe trade fair from April 12 to 16, 2021, identifies the causes of production losses in connected equipment and makes…

Delivered components have to undergo an incoming goods inspection to ensure they are correctly dimensioned and everything else is just right. MARQUIS – a software solution comprising machine learning and augmented reality – will be able to inspect components and their assemblies while on the move and in real time. Researchers at the Fraunhofer Institute for Computer Graphics Research IGD are set to showcase the technology at the Hannover Messe from April 12-16, 2021. Quality control is key to the…

Hannover Messe Digital Edition 2021: Hydrogen Technologies … To create a sustainable road traffic system, hundreds of thousands of fuel cells will be needed for hydrogen-powered cars in the future. Until now, though, fuel cell production has been complex and too slow. The Fraunhofer team is therefore developing a continuous production line that will be able to process fuel cell components in cycles lasting just seconds. The pilot line is set to be presented at the Hannover Messe Digital Edition…

Fraunhofer researchers have developed an innovative process for the initial testing of sheet metal in production systems. The process involves combining tried and proven load tests with an AI software solution. Even before the first machining step, the software creates a prediction about how the material will behave during production and gauges whether it will meet quality requirements. This drastically reduces the risk of failure and amount of scrap. Sheet metal is now used as a material in practically every…

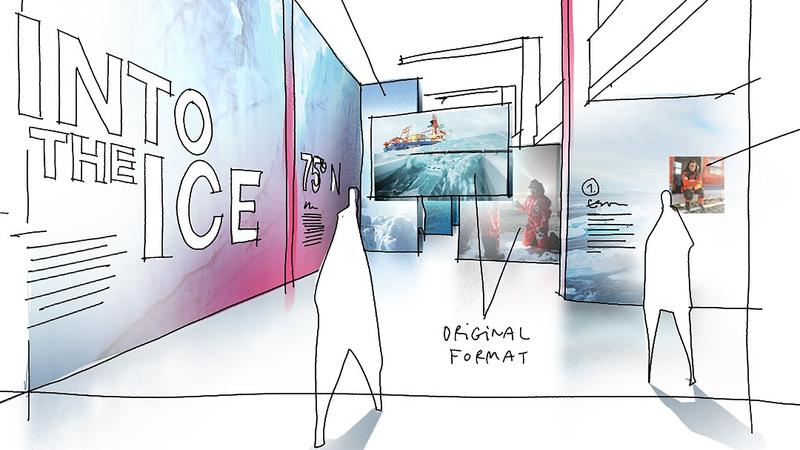

How do oceans and shipping shape our lives? What influence do we have on the oceans? “Man and the Sea – What the Oceans Mean to Us” – this is the title of the new exhibition focus presented by the German Maritime Museum (DSM) / Leibniz Institute for Maritime History on the occasion of the UN Decade of Ocean Exploration for Sustainable Development. During the current corona-related closure of the museum, preparations for new special exhibitions are in full swing….

The Ferdinand-Braun-Institut (FBH) will present its research results targeting energy-efficient amplifier concepts as well as terahertz (THz) components and systems for broadband communication and imaging at the virtual “European Microwave Week” (EuMW). In addition to its conference contributions, FBH exhibits from January 12-14, 2021 at the joint booth of the “Research Fab Microelectronics Germany” (FMD) in ex-hibition hall 3 – with FBH scientists available for a virtual exchange. The relevance of the internet is even growing in times of pandemics…

Accelerating the additive production of metal components by at least a factor of 10: With this goal in mind, the Fraunhofer-Gesellschaft launched the lighthouse project “futureAM – Next Generation Additive Manufacturing” in 2017. As the project ends in November 2020, six Fraunhofer institutes have made technological leaps forward in systems engineering, materials and process control as well as end-to-end digitalization, thus increasing the performance and cost-effectiveness of metal-based additive manufacturing along the entire process chain. On the one hand, the…

IVAM joint booth at CMEF The China International Medical Equipment Fair (CMEF) is regarded as the leading medical equipment trade fair in the Asia-Pacific region. After a successful premiere in spring 2019, the IVAM Microtechnology Network will again present a joint booth for international high-tech suppliers at the fair in Shanghai. CMEF 2020 has been postponed from April to October 19-22, making it one of the first major international medical technology platforms that will take place again under strict security…