Paradigm shift in Paris: Encouraging an holistic view of laser machining

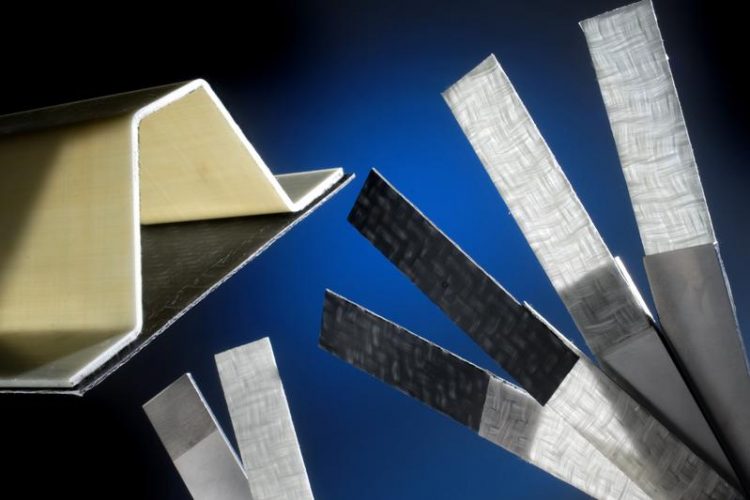

Laserjoining of FRP and hybrid joints between FRP and metal. © Fraunhofer ILT, Aachen, Germany

No other industry has attracted as much public attention to composite materials as the automotive industry, which along with the aerospace industry is a driver of innovation and growth. In other industries too, composites are now becoming increasingly important. Yet users all face the same issue: the problem of finding suitable processing methods for their products.

Lasers change the whole process chain

Suitable for applications such as welding, cutting, ablation, drilling and thermoplastic tape laying, etc., this is where lasers come in. This puts lasers in competition with classical processes. Dr.-Ing. Alexander Olowinsky, Group Manager Micro Joining at Fraunhofer ILT, Aachen, says: “When it comes to cutting and drilling, mechanical techniques such as milling, sawing or water-jet cutting are typically employed. For joining materials, adhesive bonding is the preferred method.”

When switching to lasers, however, it is always a matter of changing over to a completely different manufacturing process. Newcomers to this should talk to experts and define very precisely their requirements for the composite component. This will result in a number of options ranging from a low-cost but somewhat lower quality process to slower technology that is more expensive but of a higher quality.

Process control plays a key role

All processes have one common denominator: their quality and efficiency depend on process control. ILT scientists are looking in detail at various methods for achieving this. Dipl.-Wirt.Ing. Christoph Engelmann, Team Leader Polymer Processing, gives some examples: “With welding, constant monitoring of the temperature is important because of decomposition. When it comes to cutting, we have to employ special optical coherence tomography (OCT) sensors which enable us to determine and adjust the distance between the cutting head and the workpiece.”

An additional issue is that it is no longer sufficient just to monitor and regulate a process. Manufacturers of hybrid components cannot rely on random samples, they must document the entire manufacturing process. Laser technology’s visual accessibility enables manufacturers to produce the required production documentation.

Joining technology is a good example. Here, lasers change the entire process chain and all its prepatory steps. This allows laser joining to be performed without typical disadvantages such as long adhesive hardening time. Dr. Olowinsky says: “Unfortunately, just comparing the supposedly lower-cost adhesive bonding with the mere process of laser joining disregards the upstream and downstream process steps. That is why in Paris we want to encourage decision-makers and developers to take an holistic view of the entire process.”

Forming undercuts in the surface structure of metals more quickly

Laser-based hybrid joining begins with preparation of the metal surface. When it comes to bonding plastic and metal, the options are surface microstructuring using a CW laser, or alternatively micro- and nanostructuring using an ultrashort pulsed laser with a variety of machine concepts. In Paris, theteam will present the ComMUnion project – at the heart of which lie high-speed laser texturing and laser-assisted CFRP tape placement with integrated process monitoring. For the laser texturing process, the Aachen researchers are developing a polygon scanner system for beam guidance that will enable undercut structures to be generated considerably more quickly than was possible until now.

Mass production of hybrid components – to be used in car bodies, for example – is what the EU-funded project FlexHyJoin is all about. The aim is to reduce processing time and manufacturing costs in the production process by using a new and fully automatic joining process for metal and thermoplastic fiber-reinforced polymer composites. To this end, induction and laser welding are carried out together in a fully automated production cell. In Paris, Fraunhofer ILT will be showcasing a roof bow as the fruits of its research activities. The demonstrator is used as the connecting element between the B-pillars, and it consists of two connection nodes made of metal as well as a connecting element made of polyamide reinforced with biaxial glass fiber fabric.

Paradigm shift in the welding of plastics

At the JEC, Fraunhofer ILT will also be presenting new developments in laser transmission welding techniques for joining plastics with a metallic component. In the past, laser welding often failed here due to material thicknesses and filler materials. Through a number of research projects, the Aachen researchers aim to tackle this problem by using long-wave beam sources in the near-infrared range up to 3000 nm. Thanks to the many different beam sources available today, the way of working has changed. Dr. Olowinsky says: “We now modify the wavelength of the lasers to match the material, whereas in the past it used to be the other way around. That is the essential paradigm shift in the welding of plastics.”

At the joint booth, the researchers will also be presenting new developments in the field of laser cutting and drilling. The challenge here is to minimize the interaction between laser and composite. To achieve this, Fraunhofer ILT relies on pulsed laser beams and very rapidly deflected CW radiation, which penetrates ever deeper into the material over the course of several scans. The same also applies to laser drilling, which the Aachen researchers effectively use to cut form-locking contours into preforms.

Fraunhofer ILT at the JEC World Composite Show

In Paris visitors can find out more about composite processing and the current state of development at the joint AZL booth C55, Hall 5A from March 6-8, 2018.

Contact

Dipl.-Wirt. Ing. Christoph Engelmann

Micro Joining Group

Telephone +49 241 8906-217

christoph.engelmann@ilt.fraunhofer.de

Dr.-Ing. Alexander Olowinsky

Group Manager Micro Joining

Telephone +49 241 8906-491

alexander.olowinsky@ilt.fraunhofer.de

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…